- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Synchronizing Purchase Scheduling Agreements with ...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Dear friends of TM,

In a procurement scenario it's possible that there's an outline agreement between supplier and customer to supply products for a longer period in time. Thereby, it may occur that the recipient is responsible for parts of the transport from an incoterm location or from the supplier to the final destination. And here, it can occur that the requested delivery date from the purchase scheduling agreement changes during transport planning on customer side e.g. due to the availability of transport vehicles.

To handle this, TM provides the possibility to synchronize the delivery dates in the purchase scheduling agreement with the delivery dates from transport planning when MM and TM are on the same SAP S/4HANA system.

Scenario description

The integration of purchase scheduling agreements with TM in a single SAP S/4HANA system runs basically as follows:

- Material Requirements Planning (MRP) identifies the demands (quantity & delivery date) for a certain product.

- The purchase scheduling agreement creates and updates schedule lines for those demands.

- Freight unit building in TM creates and updates freight units based on the calculated open quantity and delivery dates from the schedule lines.

- Delivery dates of the freight units can be updated by transport planning. Therefore, report /SCMTMS/TM_SAG_PLANNING_SYNC synchronizes the schedule lines accordingly with the delivery dates from TM.

Of course, there are other use cases that also influence the delivery of a freight unit. For instance, assume the customer picks up the cargo at any handover location. Then it may occur that the delivery of the supplier to the handover location is delayed or that the quantity differs from what has been purchased, indicated e.g. by a respective advanced shipping notification (ASN).

Such scenarios are not intended to be covered by the synchronization report described here. It only targets situations where the customer adjusts his own planning.

Imagine for instance the supplier sends an ASN with a delay of a transport of one or several days. In certain situations this could now be a big challenge for the synchronization report to deal with in terms of identifying and adapting the corresponding schedule lines of the purchase scheduling agreement. Those can't automatically be changed by any ASN of the supplier as they need to reflect the actual demands of the customer. So this should better be resolved by a human being than by a fixed algorithm which could lead to inconsistent and unwanted situations, impacting the supply of the demanded products severely. In future, this might well be a scenario for AI.

We will now discuss the report in the following.

Description of the synchronization report

At first it has to be kept in mind that the purchase scheduling agreements are constantly updated by the regular MRP run. To be precise, the MRP run updates the schedule lines in terms of delivery dates and quantities according to the identified demands.

Here, it has to be ensured that there are no interferences with updates 'back and forth' from the MRP run and the report synchronizing the schedule lines with the transport planning.

Therefore, the synchronization report considers only schedule lines which are protected against updates from the MRP run. Those schedule lines are in the so called 'fixing horizon'. This fixing horizon can be maintained on purchase scheduling agreement item level with the settings for firm zone and trade-off zone.

To explain this fixing mechanism in detail, let's first take a look at the selection screen of the report:

Here, you see the planning time fence which can be provided by the user and has the following semantics:

- If a planning time fence is provided, it's taken as the fixing horizon. So, only schedule lines with delivery date within the fixing horizon are considered.

- Otherwise, the fixing horizon depends on the MRP binding setting, as maintained in the purchase scheduling agreement item.

As an example, take a schedule line with a delivery date in 10 days from today. If now a planning time fence of 5 days is provided the schedule line is not considered by the report as it's outside the fixing horizon (in this case determined by the planning time fence) and could potentially be changed by MRP again. Elsewise, all schedule lines with a delivery date from today until 5 days in the future are considered by the report.

In addition, the usage of the report is shown now with an example.

Example

Assume, we have a purchase scheduling agreement with a delivery of a product two times a week:

To simplify, the already delivered schedule lines are not shown and we assume the next delivery is due for the first schedule line with delivery date on December 15th.

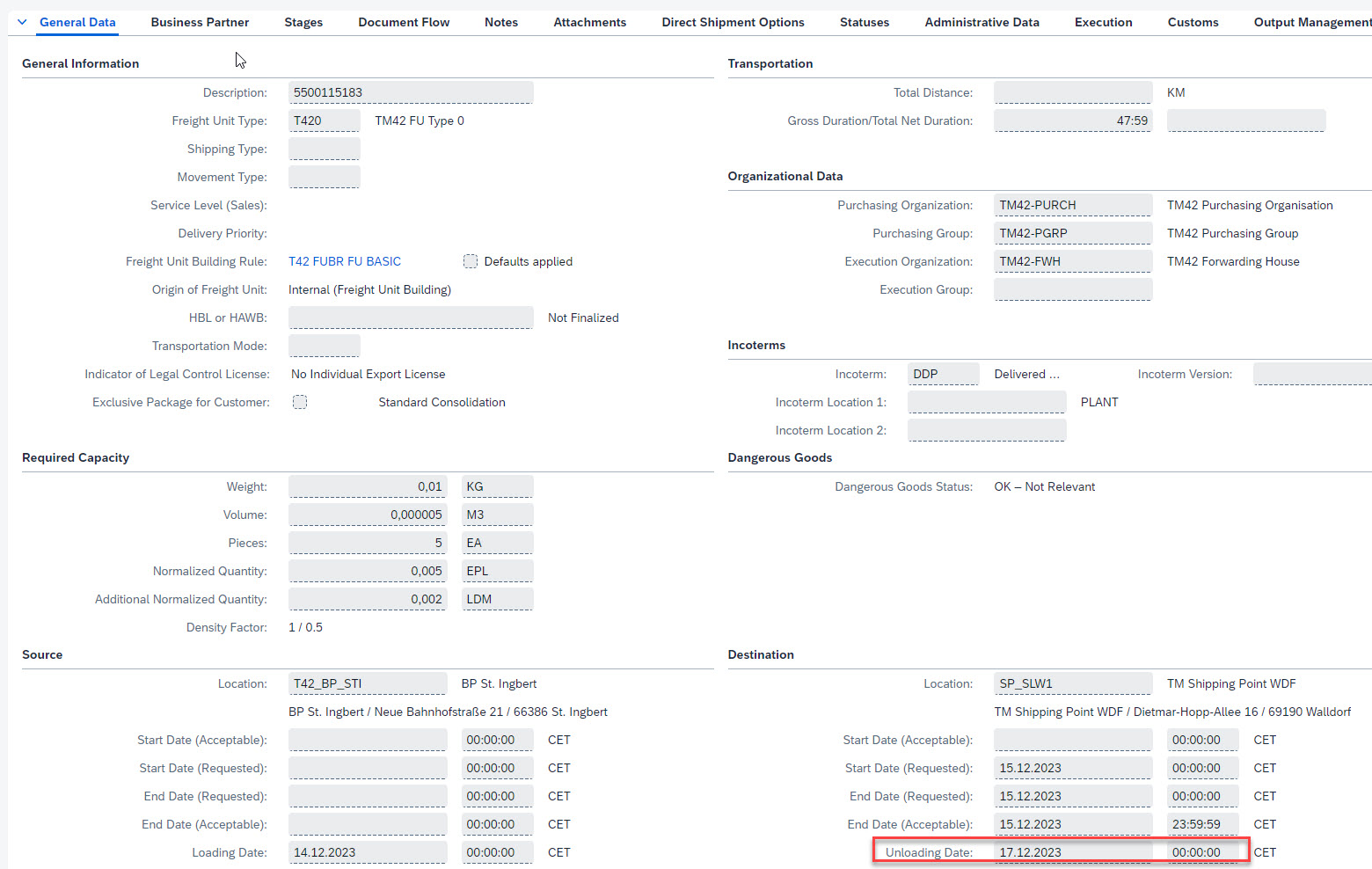

During TM integration, a respective freight unit is created for this transport requirement. This freight unit is then planned on a freight order. Now, during transport planning it turned out that the delivery is only possible at December 17th which is reflected in the freight order and the freight unit:

Usually, the synchronization report runs periodically for a bunch of purchase scheduling agreements. E.g., it runs every night for all purchase scheduling agreements of a particular purchasing group.

After the report has run, the respective schedule line is updated with the new delivery date from transport planning:

So now, transport planning of the freight unit and its respective schedule line of the purchase scheduling agreement are synchronized.

I hope this helps you to set up your procurement scenarios with TM integration. Appreciate your feedback and comments!

Best regards,

Michael

- SAP Managed Tags:

- SAP Transportation Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

41 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

67 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- Scheduling Agreement failing in Ariba CIG in Supply Chain Management Q&A

- The credit check is not preformed for the sales scheduling agreement in Supply Chain Management Q&A

- SAP S/4HANA 2023 FPS1: Improved integration of purchase scheduling agreements with TM in Supply Chain Management Blogs by SAP

- System allows to deliver more than the planned scheduling agreement quantity in Supply Chain Management Q&A

| User | Count |

|---|---|

| 7 | |

| 4 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |