- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Accelerating Machine Learning for Intelligent Asse...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member30

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-25-2018

6:19 AM

by vineet.hingorani2#overview and robertmeusel#overview

The rise of Internet of Things in the context of Industry 4.0 has introduced many new possibilities and use cases to the area of asset management. Asset management, in the old-world context was about reactive maintenance and traditional operational expense-based planning for classically sold equipment. In the new world, sensor data coming from machines paired with analytical capabilities and machine learning, asset management can be transformed into pro-active maintenance and critically-based maintenance planning enabling pay-per-use and equipment-as-a-service selling strategies.

Although a large fraction of asset manufacturers and machine operators are technically entering the era of Industry 4.0 by moving to IoT-enabled machines, the full potential on the process level is still largely untapped. One reason is the lack of technical capabilities to derive useful insights from the newly available data and allowing the end user to directly leverage the potential of these insights. A second reason is the lack of human resources to customize and enable machine learning for customer-specific assets and systems of assets.

The first challenge can be addressed by either enabling the underlying software with available machine learning libraries such as SAP PAL on HANA and custom extension or by the inclusion of machine learning services via API such as those of the SAP Machine Learning foundation. By comparison, the second challenge is more difficult to address. Following the CRISP-DM process, in common cases, knowledge about the application and processes, as well as experience with data science is required, which usually is distributed over at least two persons. Besides, a machine learning model trained to predict failures for a specific kind of pump might only be transferable to other kinds of pumps to some extent. In addition, in the case of new kinds of failures, the model needs to be retrained. These facts make the scaling of infused machine learning into business processes expensive and time consuming, not only in the domain of asset management.

Since the data scientist is the obvious bottle neck, the solution to the problem is rather obvious: reduce the necessity of this role by enabling engineers, machine operators, and fleet managers to leverage the potential of machine learning directly. This means, the major challenge in accelerating intelligence in asset management is enabling the domain expert to quickly make use of the data and the analysis from machine learning capabilities and productize them in daily business processes without having to become an expert in data integration, data preparation, machine learning or software programming. This acceleration of end users to enable the potential of their data requires the synergy of multiple components and factors.

An essential to enabling a domain expert to work on the data is the creation of a common data understanding and data model which is shared between all stakeholders. Such a data model describes not only master data or financial data, but includes also data about operational events (e.g., work orders, notifications, alerts) and semantically described data from the machine sensors (like temperature or vibration). Displaying the raw data combined with the semantic description of the asset enables the domain expert to understand the displayed data and get first insights from it.

Besides the visual inspection of data, which can be challenging, especially depending on vast amounts of time series data, automated analysis capabilities tailored towards asset management relevant problems are necessary to accelerate the end user in leveraging the data potential. Besides the visual inspection of data, which can be challenging, given the potential vast amounts of time series data, automated analysis capabilities specifically tailored for application in asset management relevant problems become necessary to accelerate the end user in leveraging the insight held within the data. Currently, due to large amounts of cheap, on-demand computing resources, evaluating several machine learning algorithms and configurations in parallel no longer requires a lot of investment and reduces the necessity for a data scientist or machine learning specialist. In addition, current research focusing on the optimization of these kinds of search problems (multiple possible algorithms times multiple hyper parameter configurations times multiple generated data features) accelerates these automated tests.

When enabling end users to make use of methods from other domains, the potential ambiguity of the used vocabularies is an important, often unappreciated factor. Within the asset management domain, common machine learning terms need to be translated to be naturally understandable by domain experts. This translation is crucial to enable the consumption of the calculated results, especially, in the domain of machine learning where results are often probabilistic, and engineers are more used to deterministic results. Furthermore, in machine learning infused processes, controllability of outcome and the direct influence on future outcomes is a key factor in establishing trust with the end user.

SAP Predictive Maintenance and Service (PdMS), part of the SAP Intelligent Asset Management portfolio, focuses on the acceleration of the operational aspects of asset management. The solution focuses on the improvement of service profitability, the reduction of maintenance costs and the increase of asset availability.

One core feature to achieve the previous stated benefits is the identification of the asset health, based on physical conditions but also enabled by machine learning capabilities identifying hidden patterns in the sensor data. This is realized within the Machine Learning Engine (MLE) which is delivered as part of SAP Predictive Maintenance and Service, available in both cloud and on-premise editions. It enables engineers along with domain experts to calculate health indicators, based on selected assets and customer-specific machine learning models. The MLE models mirror physical conditions, and sophisticated algorithms help identify hidden patterns and dependencies within the sensor data. Users can execute pre-delivered algorithms to detect anomalies, predict upcoming failures for individual assets, or take a view of their entire fleet.

Since the 1805 release of SAP Predictive Maintenance and Service, the MLE makes use of the SAP Asset Central as a unified way to describe and store or reference asset specific data, such as master data, event data but also sensor data. Across SAP, Asset Central is the reusable foundation layer whenever asset data is managed and is currently integrated into a large set of other applications such as SAP Asset Strategy and Performance Management (ASPM), SAP Asset Intelligence Network (AIN) and SAP Predictive Engineering Insights (PEI) within the SAP Intelligent Asset Management portfolio.

Asset Central enables the domain user to select and prepare machine data in a way which is natural for them, as the data model is like the one used to organize their daily work. The MLE later takes the selection based on the Asset Central model and transforms the data automatically so the underlying algorithms can make use of it. Further, the MLE transforms the results back into the Asset Central data model to enable all other applications to make use of the insights.

Since mid of 2018, the MLE in SAP PdMS offers automated algorithms for failure prediction as well as anomaly detection. The MLE makes use of state-of-the-art techniques to optimize the search for the best suitable setup for a given problem. This enables end users (not primary data scientists) to make use of complex and highly specialized methods, without the necessity of being or becoming an expert in machine learning. Of course, these capabilities can also help data scientists to scale their work when building predictive or descriptive models for multiple different (groups of) assets. In addition, as SAP understands that there are highly specialized operators and manufacturers which have gathered years of expertise for specific assets, SAP PdMS enables them to deploy and productize their algorithms. The extensibility for the MLE was included in the 1808 release for SAP internals to access and will be rolled out shortly to end customers. This functionality enables clients and customers to enhance SAP PdMS core functionality with asset-specific capabilities and to infuse their own asset-specific knowledge into the standard product.

In the next releases, SAP PdMS together with Asset Central will further automate the consumption and productization of machine learning-based capabilities. In a first step, machine learning-based results will be extended by explanations. This enables the end user to explore why a certain result is shown. Furthermore, the ability to directly give feedback and thereby influence the future outcomes of the underlying calculation will improve end user trust. The given feedback can automatically be incorporated by the underlying processes to improve over time. This methodology will help to keep the underlying machine learning models on a stable reliability level even if a new component is installed in the pump or a new operator takes over, both of which might cause a change in the underlying patterns in the data.

The rise of Internet of Things in the context of Industry 4.0 has introduced many new possibilities and use cases to the area of asset management. Asset management, in the old-world context was about reactive maintenance and traditional operational expense-based planning for classically sold equipment. In the new world, sensor data coming from machines paired with analytical capabilities and machine learning, asset management can be transformed into pro-active maintenance and critically-based maintenance planning enabling pay-per-use and equipment-as-a-service selling strategies.

Customer Requirements and Challenges

Although a large fraction of asset manufacturers and machine operators are technically entering the era of Industry 4.0 by moving to IoT-enabled machines, the full potential on the process level is still largely untapped. One reason is the lack of technical capabilities to derive useful insights from the newly available data and allowing the end user to directly leverage the potential of these insights. A second reason is the lack of human resources to customize and enable machine learning for customer-specific assets and systems of assets.

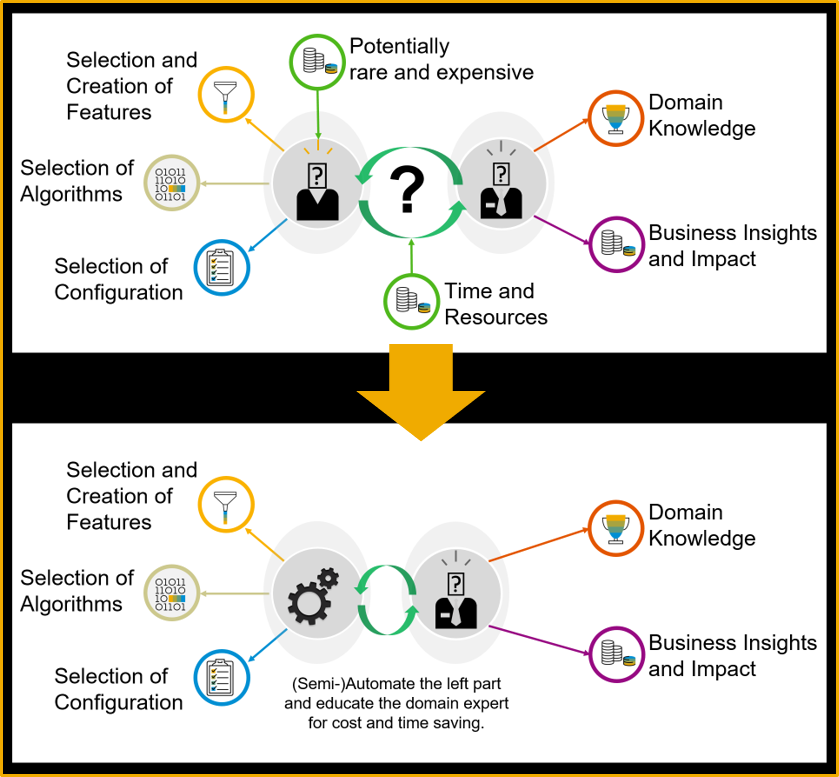

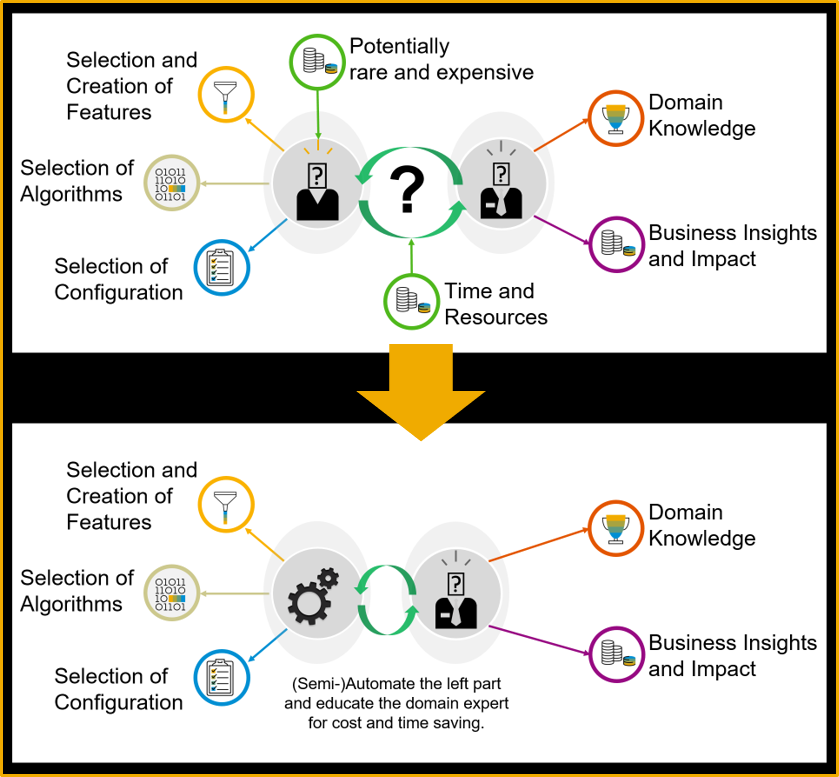

The first challenge can be addressed by either enabling the underlying software with available machine learning libraries such as SAP PAL on HANA and custom extension or by the inclusion of machine learning services via API such as those of the SAP Machine Learning foundation. By comparison, the second challenge is more difficult to address. Following the CRISP-DM process, in common cases, knowledge about the application and processes, as well as experience with data science is required, which usually is distributed over at least two persons. Besides, a machine learning model trained to predict failures for a specific kind of pump might only be transferable to other kinds of pumps to some extent. In addition, in the case of new kinds of failures, the model needs to be retrained. These facts make the scaling of infused machine learning into business processes expensive and time consuming, not only in the domain of asset management.

Integration & Automation

Since the data scientist is the obvious bottle neck, the solution to the problem is rather obvious: reduce the necessity of this role by enabling engineers, machine operators, and fleet managers to leverage the potential of machine learning directly. This means, the major challenge in accelerating intelligence in asset management is enabling the domain expert to quickly make use of the data and the analysis from machine learning capabilities and productize them in daily business processes without having to become an expert in data integration, data preparation, machine learning or software programming. This acceleration of end users to enable the potential of their data requires the synergy of multiple components and factors.

Unified Data Representation/Semantics

An essential to enabling a domain expert to work on the data is the creation of a common data understanding and data model which is shared between all stakeholders. Such a data model describes not only master data or financial data, but includes also data about operational events (e.g., work orders, notifications, alerts) and semantically described data from the machine sensors (like temperature or vibration). Displaying the raw data combined with the semantic description of the asset enables the domain expert to understand the displayed data and get first insights from it.

Automated Machine Learning

Besides the visual inspection of data, which can be challenging, especially depending on vast amounts of time series data, automated analysis capabilities tailored towards asset management relevant problems are necessary to accelerate the end user in leveraging the data potential. Besides the visual inspection of data, which can be challenging, given the potential vast amounts of time series data, automated analysis capabilities specifically tailored for application in asset management relevant problems become necessary to accelerate the end user in leveraging the insight held within the data. Currently, due to large amounts of cheap, on-demand computing resources, evaluating several machine learning algorithms and configurations in parallel no longer requires a lot of investment and reduces the necessity for a data scientist or machine learning specialist. In addition, current research focusing on the optimization of these kinds of search problems (multiple possible algorithms times multiple hyper parameter configurations times multiple generated data features) accelerates these automated tests.

Trust through Understanding and Controllability

When enabling end users to make use of methods from other domains, the potential ambiguity of the used vocabularies is an important, often unappreciated factor. Within the asset management domain, common machine learning terms need to be translated to be naturally understandable by domain experts. This translation is crucial to enable the consumption of the calculated results, especially, in the domain of machine learning where results are often probabilistic, and engineers are more used to deterministic results. Furthermore, in machine learning infused processes, controllability of outcome and the direct influence on future outcomes is a key factor in establishing trust with the end user.

Realization in PdMS with the Machine Learning Engine

SAP Predictive Maintenance and Service (PdMS), part of the SAP Intelligent Asset Management portfolio, focuses on the acceleration of the operational aspects of asset management. The solution focuses on the improvement of service profitability, the reduction of maintenance costs and the increase of asset availability.

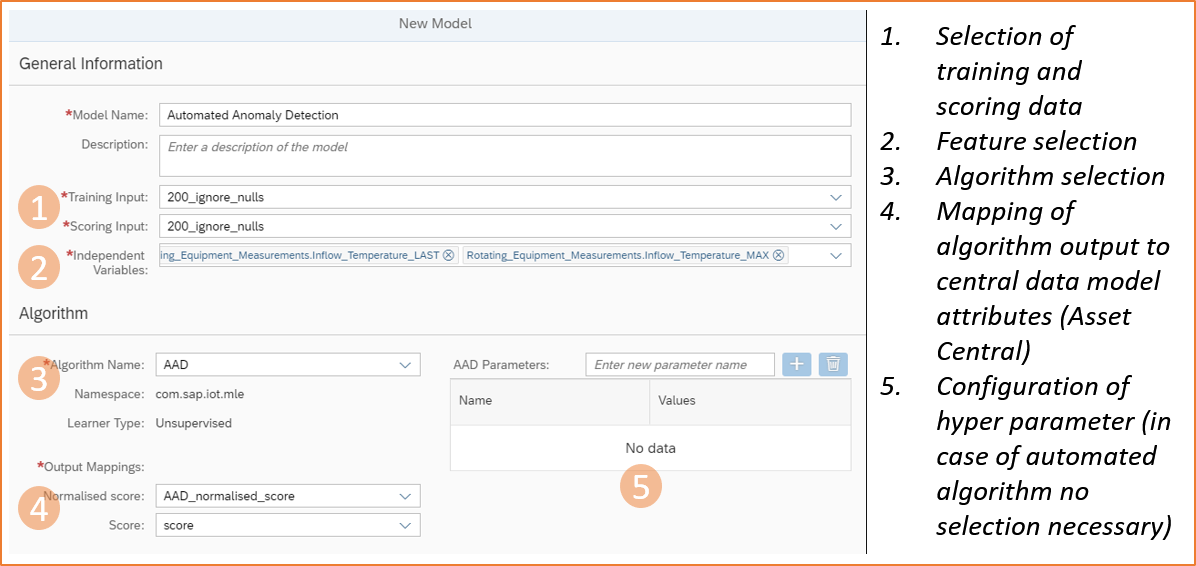

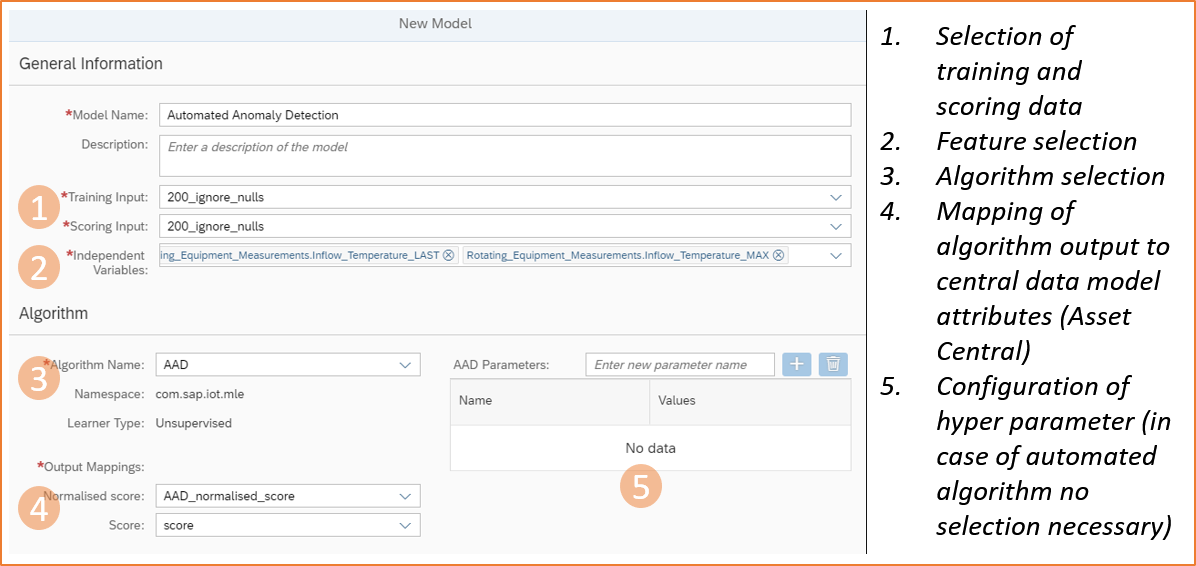

One core feature to achieve the previous stated benefits is the identification of the asset health, based on physical conditions but also enabled by machine learning capabilities identifying hidden patterns in the sensor data. This is realized within the Machine Learning Engine (MLE) which is delivered as part of SAP Predictive Maintenance and Service, available in both cloud and on-premise editions. It enables engineers along with domain experts to calculate health indicators, based on selected assets and customer-specific machine learning models. The MLE models mirror physical conditions, and sophisticated algorithms help identify hidden patterns and dependencies within the sensor data. Users can execute pre-delivered algorithms to detect anomalies, predict upcoming failures for individual assets, or take a view of their entire fleet.

Asset Central – SAPs central ontology to describe and store asset related data

Since the 1805 release of SAP Predictive Maintenance and Service, the MLE makes use of the SAP Asset Central as a unified way to describe and store or reference asset specific data, such as master data, event data but also sensor data. Across SAP, Asset Central is the reusable foundation layer whenever asset data is managed and is currently integrated into a large set of other applications such as SAP Asset Strategy and Performance Management (ASPM), SAP Asset Intelligence Network (AIN) and SAP Predictive Engineering Insights (PEI) within the SAP Intelligent Asset Management portfolio.

Asset Central enables the domain user to select and prepare machine data in a way which is natural for them, as the data model is like the one used to organize their daily work. The MLE later takes the selection based on the Asset Central model and transforms the data automatically so the underlying algorithms can make use of it. Further, the MLE transforms the results back into the Asset Central data model to enable all other applications to make use of the insights.

Automated Machine Learning and Extensibility

Since mid of 2018, the MLE in SAP PdMS offers automated algorithms for failure prediction as well as anomaly detection. The MLE makes use of state-of-the-art techniques to optimize the search for the best suitable setup for a given problem. This enables end users (not primary data scientists) to make use of complex and highly specialized methods, without the necessity of being or becoming an expert in machine learning. Of course, these capabilities can also help data scientists to scale their work when building predictive or descriptive models for multiple different (groups of) assets. In addition, as SAP understands that there are highly specialized operators and manufacturers which have gathered years of expertise for specific assets, SAP PdMS enables them to deploy and productize their algorithms. The extensibility for the MLE was included in the 1808 release for SAP internals to access and will be rolled out shortly to end customers. This functionality enables clients and customers to enhance SAP PdMS core functionality with asset-specific capabilities and to infuse their own asset-specific knowledge into the standard product.

Going Forward

In the next releases, SAP PdMS together with Asset Central will further automate the consumption and productization of machine learning-based capabilities. In a first step, machine learning-based results will be extended by explanations. This enables the end user to explore why a certain result is shown. Furthermore, the ability to directly give feedback and thereby influence the future outcomes of the underlying calculation will improve end user trust. The given feedback can automatically be incorporated by the underlying processes to improve over time. This methodology will help to keep the underlying machine learning models on a stable reliability level even if a new component is installed in the pump or a new operator takes over, both of which might cause a change in the underlying patterns in the data.

Additional Resources

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

41 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

67 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Named a Leader in the 2024 Gartner Magic Quadrant for Transportation Management Systems in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 7 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |