- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP Materials Management Introduction

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Taking that article, as an introductory step to the module Materials Management "MM". It will be your guiding article to build the base knowledge in that module. It will help you to put yourself on the track of diving deeper vertically in all the topics, that will be listed below.

SAP stands for (Systems, Applications and Products for Enterprise data processing). For SAP MM, It is an ERP system that deals with procuring, processing and production of materials with transactions such as Purchase Order (PO), Purchase Requisition (PR), Contracts, Inventory Valuation, Vendor Management and Materials Requirement Planning. SAP MM is related to the SAP ERP Logistics system. Each system needs data. For SAP MM it needs data related to the materials, vendors, plants, storage locations and inventory management. That data is called Master Data.

Let's have the cycle of SAP MM in a form of a story:

It is starts with a user requesting to purchase materials and services through manual or automated processes in the form of a Purchase Requisition (PR). After getting the approval on that request from the purchasing department. These PRs are converted to Purchase Orders (PO).

It can be considered as an external purchasing document, that will be sent to the vendor. Vendors are now aware with the material required. Receiving the material in our stock is the process of Goods Receipt (GR). Invoices will be created by the vendor, and the payment will be done.

Receiving goods from vendors make it subject to be tested for quality. The quality needs to be good, so the goods won't return back to the vendor. Having the quality checked, and everything is good. The goods will be sent to the stock.

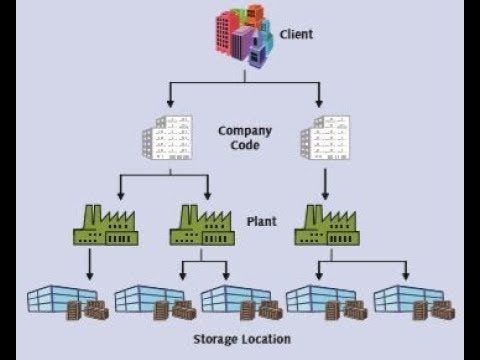

Let's check the organization structure for SAP MM:

In SAP MM, The highest level in the org. structure is the "Client". Inside the client, there can be multiple company codes, which are the legal entities within the org. structure. Inside these company codes, there can be multiple plants. Inside the plants, there can be multiple storage locations, which are used to differentiate between the materials stored. There are also purchasing organizations and purchasing groups within the org. structure.

Let's discuss the Material Master Data within SAP MM:

Material Master Data contains all the data related to the material characteristics. To create a material master, some information is required such as the "Industry Sector" and "Material Type". Each material has a certain number. It can be external or internal according to the numbering system in the configuration. The data of each material are divided in the form of views. Simply views can be considered as multiple tabs, where each tab has a name and it contains information about the material. The name of the view is descriptive enough to be able to know the type of data exists within the view. The t-code used to access the material master data is "MM01".

Let's discuss the Material Types:

Material type is a way of definition for the criteria of the material. It can be used to differentiate between materials through the supply chain process. It is an identifier with four characters. We can have some examples of commonly used material types.

Material Types can be Finished Products (FERT). It is type of products produced in-house, as it cannot be ordered by purchasing. Based on that it has no purchasing view in the material master record. Another material type can be Raw Materials (ROH). It is type of material that is procured externally then used according to the need of the organization. It contain purchasing view, but it doesn't contain sales as it cannot be sold. Another material type Semi- finished Products (HALB). It is type of material can be procured externally, and manufactured in-house. It can contain normally the purchasing view not as the Finished Products material type, as it can be procured externally.

Let's discuss the Pricing Conditions:

They are elements that contain the pricing and discounts information about a material from the vendor. It is important for the purchasing department to know the price of the material to get it at the appropriate price. Cost of the material contain components such as the gross price, discounts, taxes and shipment costs. That cost impacts the net and effective price. Conditions help to identify the cost components, and calculate the net or effective price.

Conditions can be time dependent and non time dependent conditions. Time dependent conditions have a defined period of time, which it is duration of applicability of the condition. Time dependent conditions can be used of purchase documents such as (PO, PR, etc.), while non time dependent conditions can be used in the info records. Info records are used to link a material to a vendor and price. It can be at the plant or purchasing organization level.

Let's discuss the Account Assignment Category and Item Category:

Account Assignment Category is used to categorize different needs of materials, and services. Different kinds of account category are needed for cost objects such as assets, production orders and cost centers. It can differs according to the requirements of Goods Receipt and Invoice Receipt. Let's have some examples for more clarification. Regarding the assets, the main asset number, and sub numbers are required. Regarding the cost center, the cost center number and G/L account number are required for account assignment.

Item category identifies the way of procurement for the material or the service. Some examples of item categories, It can be standard, consignment, subcontracting, stock transport order, and third party type.

Let's discuss the Inventory Management in SAP MM:

Inventory management is used to store, and issue the goods. Goods have shelf life time, which is the expiry date of the goods. It is important to put them in batches, so all goods with the same expiry date should be kept together in one place. There are many activities included in the inventory management such as Managing Goods Receipts (GRs), Goods Issue (GI), physical inventory, Goods Return Management, Batch Management, Material Valuation, and Stock Transfer.

There are three different types of material statuses. The Unrestricted-use stock, It is where materials can be used and transferred normally. The Inspection Stock, It is where materials are inspected to check it's quality. The Blocked Stock, It is where materials can be transferred to inspection or unrestricted use.

- SAP Managed Tags:

- SAP ERP,

- MM (Materials Management),

- MM Inventory Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- Announcement: New integration platform in SAP Business Network for Logistics in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- SAP EWM FAQ Series: How to setup monitoring and alerts in Supply Chain Management Blogs by SAP

- Freight Generation in Data Collation Document using Freight Rate Table or Pricing Multireference in Supply Chain Management Blogs by Members

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |