- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- On-demand additive manufacturing-3D printing netwo...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Today manufacturing companies are challenged to produce individualized products in an environment of constantly changing and varying customer demand in highly volatile market.

With emergence of demand for individualized products,life cycles of products gets shorter , faster time to market is the key for staying competitive. The demand for customer personalization leads to complex products variants ,this would force companies to be agile and more responsive to market needs.

Responsive to market disruptions and growing customer demands : COVID certainly have exposed the sensitivities of traditional manufacturing and supply chains.linear soiled manufacturing with point-to-point integration will not be able to handle constantly changing customer requirements and market disruptions.Modular manufacturing and autonomous guided vehicles will be the future of manufacturing in hyper local production environment would be the future.

With that said , with huge demand for customer personalisation predicted ,a)will the centralized manufacturing holds good to cater future requirements b) Demand for customer personalisation leads to complex product variants which open doors for complex spare part maintenance .

It is highly impossible to maintain spare inventory for complex product variations, on the flip side . one of the major disadvantages of excess inventory is loss of revenue . The longer you hold , the cheaper it gets . Unavailability of right spare part in right time will leads to loss of production,un-planned down times and loss of customer experience and trust .

Lot size one manufacturing with mass customization will give birth to emergence of micro plants ( Hyper local manufacturing ) .Hyper local production literally means plants operating in physical proximity to high density population .

Hyper local plants

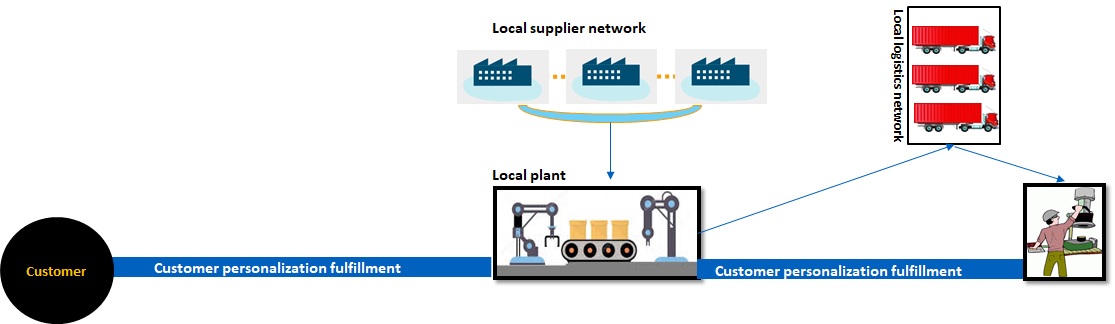

Micro plants will be available locally based on predictive customer demands with local supplier network , Micro plant could be a small assembly line or set of 3D machines or even could be mobile shipping container that could accommodate a set of machine/3D printers . Not all the products are manufactured in local plants , rather it is a choice that manufacture has to make based on many factors a) Customer segmentation or jobs to be done b)Region specific product variants c) Predictive models d) Which products can be make local vs central . As a consequence a sub-set of supply chain will be created which appeal to the on demand customers . A network of local suppliers can reduce the total time of manufacturing drastically . This would be a significant win for customers in terms of reduced turn around times and shipping cost.

Today , as an asset operator , if my asset is down for repair or predicted repair in next two weeks , i can receive spares from manufacturer's dealer in same country or manufacturer in another country or vice-versa . The end result is always the same, the spare has to be shipped from miles away from the asset location.Availability, Planning ,transportation of spare is very critical in repair of machine.

With 3D additive manufacturing , a network of 3D printing machines located in local plants which are the sole property of manufacturer or individual 3D printing machines subscribed with manufacturer by partner spread across location monitored centrally.

3D printing network( Additive manufacturing network)

Assume a scenario , where manufacturer is centrally located in New delhi, a network of 3D printing machine spread across the country like bangalore,chennai,hyderabad,pune etc .These 3D printing machines nominated to serve in specific location will be managed by manufacturer ( registration , qualification etc), once qualified , will be allowed to serve in local location in printing spare. The request received by manufacturer from specific location will be transferred to local 3D machine to serve local customer/operator.

The entire life cycle of manufacturing spare by 3D printer and transportation will be monitored by manufacturer in centralized application . This would be huge cost advantage in terms of zero spare inventory ,reduction in shipping cost by huge margin as it is shipped locally. Speed of repair and spare availability in near real-time would be revolutionary change.

It is not surprising that a container fleet that can carry a 3D printing machine to customer/operator's premise for quick printing .These fleet could be maintained in logistic business network for process optimization and could be integrated to asset intelligent network .

On demand manufacturing

On demand distributed manufacturing combined with logistics business networks in hyper local production environment would be the theme of the manufacturing future .

Source &References:

(https://www.sap.com/documents/2019/12/7eb945d8-777d-0010-87a3-c30de2ffd8ff.html)

https://news.sap.com/2020/11/creating-network-of-networks/

https://podcasts.apple.com/in/podcast/the-digital-supply-chain-podcast/id1466599957?i=1000497440557

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Change History

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

FINANCE

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Material Master changes

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- Material master labels print out transcation in Supply Chain Management Q&A

- Sequencing of spools for different inbound deliveries in Supply Chain Management Q&A

- Custom Handling unit label printing using PPF actions in EWM in Supply Chain Management Blogs by Members

- Handling Unit Label Printing Through PPF in SAP EWM in Supply Chain Management Q&A

- SAP EWM Physical Inventory count sheet Print Automatically after PI Document Active in Supply Chain Management Q&A

| User | Count |

|---|---|

| 7 | |

| 4 | |

| 4 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |