- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Scheduling Parameters in Maintenance Plan

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

sriram_007

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-30-2023

5:23 PM

Objective :

The Main Objective of this Blog post is to explain how the Scheduling parameters are Functioning on the calculation of the Plan date in Preventive Maintenance - Single Cycle Plan

Scheduling Parameters :

Here we maintain the Scheduling Parameters for the single cycle plan directly in the maintenance plan as shown as below.

There are 3 types of scheduling Indicator

- Time

- Time- key date

- Time-factory calendars

Based On Time Scheduling Indicator:

According to the Time scheduling indicator, the calculation is based on every 30 days all the calendar days should get counted for example if I give 01.08.2023 it will calculate after 30days. i.e 31.08.2023 is the plan date.

Based on Time-Key Date:

According to the Time-key date indicator, the calculation is based on effective days of the month i.e If I give 01.08.2023 as start date , the plan date occurs on 01.09.2023

Based on the Factory Calendar :

The basis of month always 30 days ; Only the factory calendar dates are get counted. i.e Cycle one month , factory calendar Saturday/Sunday/Public holiday free , start of cycle 01.08.2023 results in plan date of 13.09.2023 . Selecting the Indian (IN) calendar.

Call Horizon :

The Call Horizon determines when a maintenance call object, for example, a Maintenance Order should be generated for a Maintenance Call.

A percentage that determines how much time must pass after the start or completion confirmation date of a maintenance plan before the system creates a maintenance call object, for example, a maintenance order or a service entry sheet, for a calculated maintenance date (planned date).

If no current completion confirmation date is available, the last planned date is used as a starting date for calculating the call date for the maintenance call objects.

For example;

If the duration of the cycle is 150 days and the call horizon is 0 %, 80%, or 100%, the system creates the order after the following number of days:

- 0% - Immediate call

- 80% - Call after 100 days (= 80% of 150 days)

- 100% - Call after 150 days, on the planned date

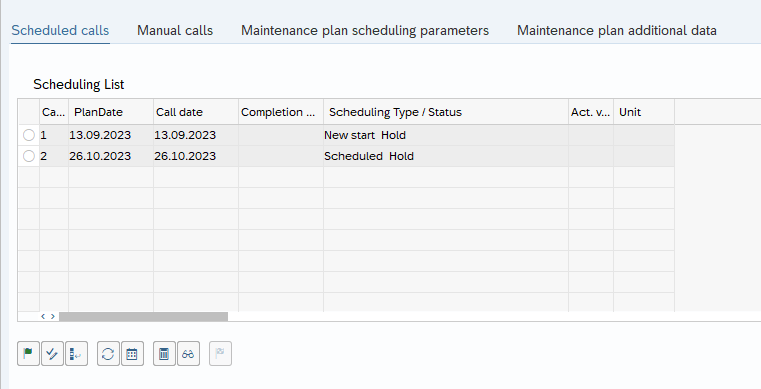

For 0% of call horizon :

The Schedule will appear like this :

For 90% of call horizon :

By the same way if the call horizon is 90%

For 100% of call horizon :

By the same way if the call horizon is 100%

Completion requirement :

If you set this indicator, the system only generates the next Call object once the preceding call object has been confirmed.

If incase you're planning to release the second schedule, the completion requirement check box is in marked stage, the interface will not allow you to release the schedule due to the incompletion of first schedule.

Shift Factor :

Shift factor specifically for your maintenance plan by specifying the shift percentage to be taken into account when calculating the next due date.

For example the planned date for your maintenance order was 01.09.23, but it was confirmed 15 days too late on 16.09.23. The next planned date may now be on a different date since this is dependent on the shift factors entered:

If the shift factor is 0% the next planned date will be 01.10.2023

If the shift factor is 100% the next planned date will be 16.10.2023

If the shift factor is 50% the next planned date will be 08.10.2023

Tolerance :

In the maintenance plan there are two different kinds of Tolerance's

- Positive Tolerance

- Negative Tolerance

Positive Tolerance :

For a late completion, this tolerance defines the time span in which a positive deviation between the actual and planned date does not influence any subsequent scheduling.

Negative Tolerance :

For a early completion, this tolerance defines the time span in which a negative deviation between the actual and planned date does not influence any subsequent scheduling

For example, if you have created a maintenance plan for 30 days and you have defined a tolerance of 10% in the case of early completion. This produces the tolerances of 3 days. If the completion is made no more than 3 days before the planned date, the system does not consider this deviation when calculating the next planned date.

- SAP Managed Tags:

- PLM Enterprise Asset Management (EAM)/Plant Maintenance (PM)

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Proactive Order (YA02) is not generating with Notifiction type (Y2) and giving error while schedulin in Enterprise Resource Planning Q&A

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Account Balance Validation in SAP S/4HANA Cloud, Public Edition in Enterprise Resource Planning Blogs by SAP

- Scheduling parameters usage & what is forward scheduling & backward scheduling in maintenance orders in Enterprise Resource Planning Q&A

- Service with Advanced Execution and Resource-related Billing in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 4 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |