- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Production / Process Order Change Log using SAP No...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Issue Encountered:

The Revision Field in the Custom Production Order Job Card Printout was initially intended to be blank based on the Customer Template. However, the new requirement is to update this field automatically whenever there are changes to the Production Order and to reprint the Job Card with new data and a revised revision number.

Approach to Resolution:

Initially, the need arose to access the Production Order Change Log or History within any Database Tables to initiate the customization process. Regrettably, we were unable to locate any change log in both CDHDR and CDPOS for the Production Order (Order Category: 10 and 40).

Upon further investigation, we discovered that SAP has not incorporated this in the Standard Solution, as indicated in SAP Note: 390635. This is due to the fact that modifications to the Header Quantity will lead to changes in all BOM Component Quantities and Operations, resulting in an extensive list of change documents.

Link to SAP Note: https://me.sap.com/notes/390635/E

So, Consequently we opted to:

- Capture changes in the Production Order (for specific fields alone). For example, generate a change log exclusively when there is a modification in Production Order Header Quantity, creation or updates to existing lines in both BOM and Routing, while ignoring any other changes.

- Utilize the aforementioned log to automatically update the Revision Field in the Custom Production Order Job Card Printout.

Solution:

Following the guidelines provided in SAP Note: 390635, we executed the following steps:

- Coordinated with the Technical Team to create and activate the Include in (SMOD / CMOD) in Project: PPCO0007, FM: EXIT_SAPLCOZV_001, and Include: ZXCO1U06.

- Informed the Basis Team to implement SAP Note: 390635.

- Subsequently, the SAP Sample Code is automatically generated in this Include. This Sample Code serves as a reference for generating the log for changes made in Routing.

- Collaborated with our Technical Team to make the necessary modifications in this Include Program. We requested them to create a new entry whenever there is a change in Header Quantity or when there is data creation or updating in BOM/Routing.

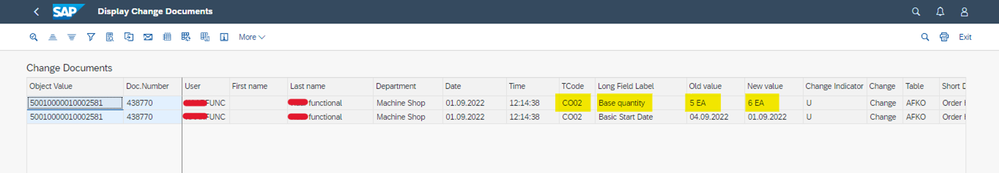

- After the Technical Team's modifications, we can observe all our changes in the Program: RSSCD100 / 150 / 200 (as specified in SAP Note).

- Enter the details below in the Selection Screen of RSSCD100 and Execute,

Object Class - ORDER

Object ID - *<Production Order Number>

Date Range - As Required

RSSCD100 Selection Screen

- The output displayed is as follows:

- If required, we can create this Program: RSSCD100 as the TCode as a Tile and Provide to the Customer.

Transitioning to the second half of the blog:

- Within the Production Order, we've activated the "Customer Screen" tab, incorporating five fields—Revision Number, Changed By, Changed On, Changed At, and Document Number. These custom fields have been added to the table.

Production Order - Customer Screen View

- Whenever changes occur in the specified fields, and a document is generated through SNote: 390635, we captured the relevant data from the posted document within the Update BAdI. Subsequently, we calculated the Revision Number and displayed it in the Production Order. It's important to note that the program has been configured to generate only one document and, consequently, record a single revision if changes are made to all the fields and saved at once.

- Leveraging this available data, we linked it to the customized Adobe Form for the Job Card Printout.

Conclusion:

We trust that this approach will be beneficial if you come across a similar scenario. If you have explored alternative methods, please feel free to comment and share your insights.

- SAP Managed Tags:

- MAN Production Planning (PP)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- SAP S4HANA Cloud Public Edition Logistics FAQ in Enterprise Resource Planning Blogs by SAP

- remove billing plan block from sales order in Enterprise Resource Planning Q&A

- Collective processing of PR's generated by MRP in S4 Hana Public Cloud in Enterprise Resource Planning Q&A

- SAP Preferred Success: A Day in a Life in Product Change Management with Change Records in Enterprise Resource Planning Blogs by SAP

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |