- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Replenishment Strategies in SAP S/4HANA Cloud Ware...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member13

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-22-2021

7:46 PM

Hello SAP Community,

Replenishment is an internal process that ensures stock of storage bin for picking is always between minimum and maximum quantity. Once stock is lower than minimum quantity, the replenishment can take place.

As of release 2105, we will have 3 types of replenishment strategies in SAP S/4HANA Cloud WM, those are:

In this blog post, I will focus on the planned replenishment strategy. In a latter blog post, I will share more information regarding the other strategies as well as the new enhancements coming with release 2105.

Characteristics of Planned Replenishment:

Environment:

SAP S/4HANA Cloud 2102

Limitations:

Replenishment Level is Storage Bin Level for Fix Bins only. As of Release 2105 we plan to provide more flexibility to the strategies.

Master Data Setup:

1. Activate Replenishment Strategy: you activate planned or automatic replenishment for fixed bin storage type by activating a replenishment strategy at Warehouse + Storage type level.

This step can be found in the Warehouse Setup Guide. In Manage Your Solution app > Supply Chain > Warehouse Management > General Settings > Activate Replenishment in Storage Types.

2. Assign fixed bins to products: in Assign Fixed Bins app assign fixed storage bins to the product, informing the minimum and maximum quantity for the bin

Note: these maximum and minimum quantities in the fixed bin are solely used for replenishment, it’s not a physical limitation, e.g. I can manually move more than 20 PC to my storage bin below

3. Set the stock removal control: the removal indicator will tell the system where to pick the stock from and what is the removal rule (e.g. FIFO). Please take a look at KBA 3075567 in case you notice your replenishment warehouse task is using the Putaway Control Indicator instead of Stock Removal Control Indicator.

You define it in Manage Product Master Data app > Warehouse Management > Stock Removal

4.Define replenishment quantity in the product master (optional): this setting defines what is the minimum quantity for the replenishment WT, and the min. and max. replenishment quantity in the storage type. For example, if the minimum replenishment quantity is 5 PC the system will not create any task for less than 5 PC and only for multiples of 5 (5, 10, 15, and so on).

You define it in Manage Product Master Data app > Warehouse Management > Warehouse > Storage Type > Replenishment

Procedures:

Call Replenish Stock app, fill in the necessary entries and Execute. Here, I’m planning replenishment for the entire ZSF1 storage type.

On the next screen, check the proposed quantity to be replenished, select the line item and choose Perform Replenishment

The WT for replenishment is then created.

Note: If the stock of TG11 is not below the Min.Qty (5 PC) in the fixed storage bin, there is no replenishment proposal. The replenishment quantity is calculated as the difference between the maximum bin quantity and the current bin quantity, and then it is rounded to a multiple of the minimum replenishment quantity.

You can maintain the minimum replenishment quantity in the product master via the Manage Product Master Data app (step 4). See the details in the master data script “Create Warehouse Attributes for Material/Product Master”.

If no minimum replenishment quantity is maintained in the product master, the system rounds the quantity with the basic Unit of Measure of the product.

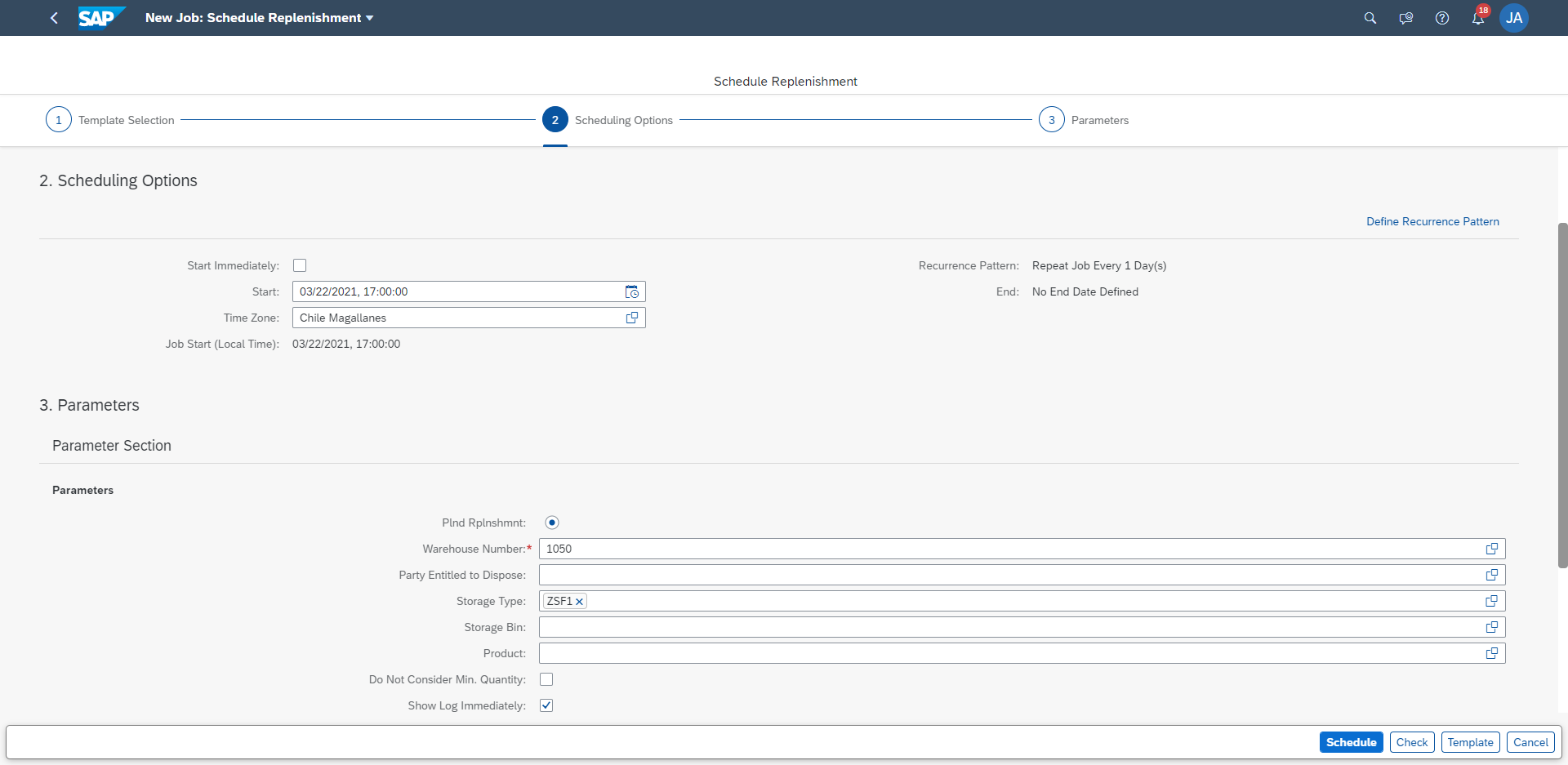

Call Schedule Replenishment app and choose New.

Select Job Template “Schedule Replenishment” and define a Job Name. Now you need to define the Scheduling Options and Parameters for the job.

In below example, my job will run everyday at 5 PM for Warehouse 1050, Storage Type ZSF1.

Conclusion

With this process, you can plan and automate the creation of replenishment warehouse tasks to ensure the right inventory levels for your product in the areas where picking is done.

At the end of the process, the warehouse operative confirms the warehouse tasks and makes sure that the stock is moved from the reserve area to the picking area.

Additional Information

SAP Help Portal Replenishment Control:

https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/a8f8c1c6de10466cb6a335df94...

SAP Help Portal Configuration for Replenishment Control:

https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/0bfbc5fe6cfb4a34af90f72307...

Best Practice for SAP S/4HANA Cloud > Supply Chain > Warehousing > Scope Item Replenishment in Warehousing (4A2):

https://rapid.sap.com/bp/#/browse/packageversions/BP_CLD_ENTPR

Please feel free to leave any comments or questions below and any additional topics you think are valuable to have included in this and future blog posts.

Replenishment is an internal process that ensures stock of storage bin for picking is always between minimum and maximum quantity. Once stock is lower than minimum quantity, the replenishment can take place.

As of release 2105, we will have 3 types of replenishment strategies in SAP S/4HANA Cloud WM, those are:

- Planned Replenishment (supported since 1911): system creates replenishment warehouse tasks if the current stock is below the defined threshold for the product’s bin. Planned replenishment can be started either manually or as a regular application background job

- Automatic Replenishment (supported since 2002): when the warehouse operative confirms a warehouse task that decreases the quantity in the storage bin to below the minimum quantity threshold, the system automatically triggers a replenishment warehouse task creation in the background

- Order-Related Replenishment (supported since 2105): in this strategy, the system calculates replenishment quantities based on the quantity of open outbound deliveries. This process can be started either manually or as a regular application background job

In this blog post, I will focus on the planned replenishment strategy. In a latter blog post, I will share more information regarding the other strategies as well as the new enhancements coming with release 2105.

Characteristics of Planned Replenishment:

- Calculates replenishment according to existing stocks in the picking area and the minimum and maximum quantities from fix bins or product master

- It's started when stock is lower than the minimum quantity

- It can be started interactively or in the background

- The system rounds down the replenishment quantity to a multiple of the minimum replenishment quantity

- Minimum quantity can be ignored

- Replenished quantity will not be higher than the maximum quantity

Figure 1. Planned Replenishment

Environment:

SAP S/4HANA Cloud 2102

Limitations:

Replenishment Level is Storage Bin Level for Fix Bins only. As of Release 2105 we plan to provide more flexibility to the strategies.

Master Data Setup:

1. Activate Replenishment Strategy: you activate planned or automatic replenishment for fixed bin storage type by activating a replenishment strategy at Warehouse + Storage type level.

This step can be found in the Warehouse Setup Guide. In Manage Your Solution app > Supply Chain > Warehouse Management > General Settings > Activate Replenishment in Storage Types.

Figure 2. App Manage Your Solution

Figure 3. Activate Replenishment Strategies customizing view

2. Assign fixed bins to products: in Assign Fixed Bins app assign fixed storage bins to the product, informing the minimum and maximum quantity for the bin

Note: these maximum and minimum quantities in the fixed bin are solely used for replenishment, it’s not a physical limitation, e.g. I can manually move more than 20 PC to my storage bin below

Figure 4. App Assign Fixed Bins

3. Set the stock removal control: the removal indicator will tell the system where to pick the stock from and what is the removal rule (e.g. FIFO). Please take a look at KBA 3075567 in case you notice your replenishment warehouse task is using the Putaway Control Indicator instead of Stock Removal Control Indicator.

You define it in Manage Product Master Data app > Warehouse Management > Stock Removal

Figure 5. Stock Removal in Product Master Data

4.Define replenishment quantity in the product master (optional): this setting defines what is the minimum quantity for the replenishment WT, and the min. and max. replenishment quantity in the storage type. For example, if the minimum replenishment quantity is 5 PC the system will not create any task for less than 5 PC and only for multiples of 5 (5, 10, 15, and so on).

You define it in Manage Product Master Data app > Warehouse Management > Warehouse > Storage Type > Replenishment

Procedures:

- Manually:

Call Replenish Stock app, fill in the necessary entries and Execute. Here, I’m planning replenishment for the entire ZSF1 storage type.

Figure 6. App Replenish Stock

On the next screen, check the proposed quantity to be replenished, select the line item and choose Perform Replenishment

Figure 7. Replenishment Proposal

The WT for replenishment is then created.

Figure 8. Warehouse Task creation log

Note: If the stock of TG11 is not below the Min.Qty (5 PC) in the fixed storage bin, there is no replenishment proposal. The replenishment quantity is calculated as the difference between the maximum bin quantity and the current bin quantity, and then it is rounded to a multiple of the minimum replenishment quantity.

You can maintain the minimum replenishment quantity in the product master via the Manage Product Master Data app (step 4). See the details in the master data script “Create Warehouse Attributes for Material/Product Master”.

If no minimum replenishment quantity is maintained in the product master, the system rounds the quantity with the basic Unit of Measure of the product.

- Background job:

Call Schedule Replenishment app and choose New.

Select Job Template “Schedule Replenishment” and define a Job Name. Now you need to define the Scheduling Options and Parameters for the job.

In below example, my job will run everyday at 5 PM for Warehouse 1050, Storage Type ZSF1.

Figure 9. App Schedule Replenishment

Conclusion

With this process, you can plan and automate the creation of replenishment warehouse tasks to ensure the right inventory levels for your product in the areas where picking is done.

At the end of the process, the warehouse operative confirms the warehouse tasks and makes sure that the stock is moved from the reserve area to the picking area.

Additional Information

SAP Help Portal Replenishment Control:

https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/a8f8c1c6de10466cb6a335df94...

SAP Help Portal Configuration for Replenishment Control:

https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/0bfbc5fe6cfb4a34af90f72307...

Best Practice for SAP S/4HANA Cloud > Supply Chain > Warehousing > Scope Item Replenishment in Warehousing (4A2):

https://rapid.sap.com/bp/#/browse/packageversions/BP_CLD_ENTPR

Please feel free to leave any comments or questions below and any additional topics you think are valuable to have included in this and future blog posts.

Labels:

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

29 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

27 -

Expert Insights

114 -

Expert Insights

174 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,683 -

Product Updates

251 -

Roadmap and Strategy

1 -

Technology Updates

1,500 -

Technology Updates

92

Related Content

- Speeding up your SAP HCM move to the cloud in 2024 - Part 2: Customer Evolution Kit for HCM in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Data Migration and Master Data Management Best Practices with SAP BTP in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Manufacturing in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Overview - Gen AI and Sustainability in Enterprise Resource Planning Blogs by SAP

- SAP Activate methodology Prepare and Explore phases in the context of SAFe. in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 29 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |