- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Automatic Replenishment in SAP S/4HANA Cloud Wareh...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member13

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-08-2021

7:34 PM

Hello SAP Community,

This is a continuation of my blog series about Replenishment Strategies in SAP S/4HANA Cloud Warehouse Management.

In my previous blog post, I focused on Planned Replenishment. In this blog post, I will focus on Automatic Replenishment and setup an example using fixed bins.

Automatic Replenishment is triggered when the warehouse operative confirms a picking warehouse task that decreases the quantity in the storage bin to below the minimum quantity threshold. The system automatically triggers a replenishment warehouse task creation in the background.

Characteristics of Automatic Replenishment:

Master Data Setup:

The Master Data Setup is very similar to Planned Replenishment.

1. Activate Replenishment Strategy: Manage Your Solution > Supply Chain > Warehouse Management > Internal Warehouse Processes > Activate Replenishment Strategies in Storage Types

2. Assign fixed bins to products: in Assign Fixed Bins app assign fixed storage bins to the product, informing the minimum and maximum quantity for the bin

Note: these maximum and minimum quantities in the fixed bin are solely used for replenishment, it’s not a physical limitation, e.g. I can manually move more than 50 PC to my storage bin below

3. Set Stock Removal Control Indicator: the removal indicator will tell the system where to pick the stock from and what is the removal rule (e.g. FIFO). Please take a look at KBA 3075567 in case you notice your replenishment warehouse task is using the Putaway Control Indicator instead of Stock Removal Control Indicator.

You define it in Manage Product Master Data app > Warehouse Management > Stock Removal

4. Define replenishment quantity in the product master (optional): this setting defines what is the minimum quantity for the replenishment WT, and the min. and max. replenishment quantity in the storage type. For example, if the minimum replenishment quantity is 5 PC the system will not create any task for less than 5 PC and only for multiples of 5 (5, 10, 15, and so on).

You define it in Manage Product Master Data app > Warehouse Management > Warehouse > Storage Type > Replenishment

Procedure:

After the automatic replenishment is customized, the system will automatically create a replenishment WT (in open status) once a picking WT that reduces the stock quantity to less than minimum quantity defined in step 2 is confirmed.

Conclusion

With this process, you can automate the creation of replenishment warehouse tasks to ensure the right inventory levels for your product in the areas where picking is done.

At the end of the process, the warehouse operative confirms the warehouse tasks and makes sure that the stock is moved from the reserve area to the picking area.

Additional Information

SAP Help Portal Replenishment Control: https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/a8f8c1c6de10466cb6a335df94...

SAP Help Portal Configuration for Replenishment Control: https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/0bfbc5fe6cfb4a34af90f72307...

Best Practice for SAP S/4HANA Cloud > Supply Chain > Warehousing > Scope Item Replenishment in Warehousing (4A2): https://rapid.sap.com/bp/#/browse/packageversions/BP_CLD_ENTPR

Please feel free to leave any comments or questions below and any additional topics you think are valuable to have included in this and future blog posts.

This is a continuation of my blog series about Replenishment Strategies in SAP S/4HANA Cloud Warehouse Management.

In my previous blog post, I focused on Planned Replenishment. In this blog post, I will focus on Automatic Replenishment and setup an example using fixed bins.

Automatic Replenishment is triggered when the warehouse operative confirms a picking warehouse task that decreases the quantity in the storage bin to below the minimum quantity threshold. The system automatically triggers a replenishment warehouse task creation in the background.

Characteristics of Automatic Replenishment:

- Calculates replenishment according to existing stocks in the picking area and the minimum and maximum quantities from fix bins or product master

- It’s only started when the stock figure is lower than the minimum quantity

- It is triggered automatically upon warehouse task confirmation

- The system rounds down the replenishment quantity to a multiple of the minimum replenishment quantity

- Replenished quantity will not be higher than the maximum quantity

Figure 1. Automatic Replenishment

Master Data Setup:

The Master Data Setup is very similar to Planned Replenishment.

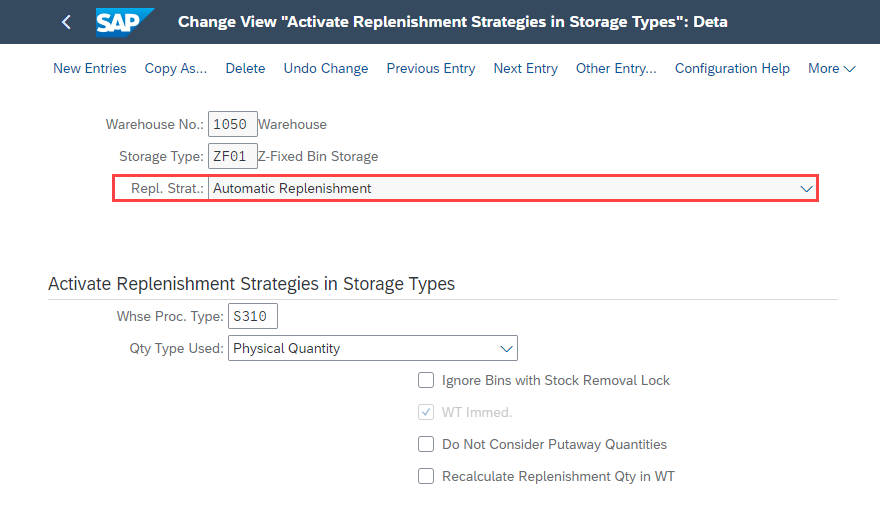

1. Activate Replenishment Strategy: Manage Your Solution > Supply Chain > Warehouse Management > Internal Warehouse Processes > Activate Replenishment Strategies in Storage Types

Figure 2. Activate Replenishment Strategies customizing view

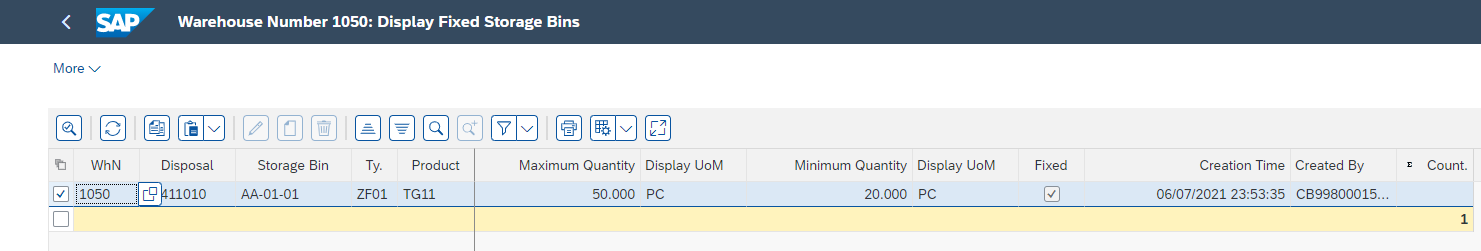

2. Assign fixed bins to products: in Assign Fixed Bins app assign fixed storage bins to the product, informing the minimum and maximum quantity for the bin

Note: these maximum and minimum quantities in the fixed bin are solely used for replenishment, it’s not a physical limitation, e.g. I can manually move more than 50 PC to my storage bin below

Figure 3. Assign Fix Bins app

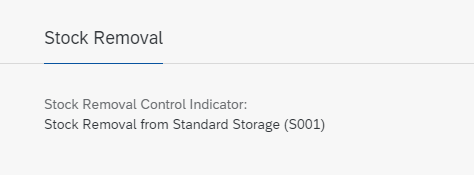

3. Set Stock Removal Control Indicator: the removal indicator will tell the system where to pick the stock from and what is the removal rule (e.g. FIFO). Please take a look at KBA 3075567 in case you notice your replenishment warehouse task is using the Putaway Control Indicator instead of Stock Removal Control Indicator.

You define it in Manage Product Master Data app > Warehouse Management > Stock Removal

Figure 4. Stock Removal in Product Master Data

4. Define replenishment quantity in the product master (optional): this setting defines what is the minimum quantity for the replenishment WT, and the min. and max. replenishment quantity in the storage type. For example, if the minimum replenishment quantity is 5 PC the system will not create any task for less than 5 PC and only for multiples of 5 (5, 10, 15, and so on).

You define it in Manage Product Master Data app > Warehouse Management > Warehouse > Storage Type > Replenishment

Figure 5. Storage Type Specific Replenishment in Product Master Data app

Procedure:

After the automatic replenishment is customized, the system will automatically create a replenishment WT (in open status) once a picking WT that reduces the stock quantity to less than minimum quantity defined in step 2 is confirmed.

Conclusion

With this process, you can automate the creation of replenishment warehouse tasks to ensure the right inventory levels for your product in the areas where picking is done.

At the end of the process, the warehouse operative confirms the warehouse tasks and makes sure that the stock is moved from the reserve area to the picking area.

Additional Information

SAP Help Portal Replenishment Control: https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/a8f8c1c6de10466cb6a335df94...

SAP Help Portal Configuration for Replenishment Control: https://help.sap.com/viewer/87f9b54f9c4f4e75aff0061860a6589a/latest/en-US/0bfbc5fe6cfb4a34af90f72307...

Best Practice for SAP S/4HANA Cloud > Supply Chain > Warehousing > Scope Item Replenishment in Warehousing (4A2): https://rapid.sap.com/bp/#/browse/packageversions/BP_CLD_ENTPR

Please feel free to leave any comments or questions below and any additional topics you think are valuable to have included in this and future blog posts.

Labels:

6 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

20 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

23 -

Expert Insights

114 -

Expert Insights

150 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,687 -

Product Updates

202 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

85

Related Content

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Stock Transfer between two EWM Managed plants assigned to same warehouse in Enterprise Resource Planning Q&A

- SAP ERP Functionality for EDI Processing: UoMs Determination for Inbound Orders in Enterprise Resource Planning Blogs by Members

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- KANBAN issue straight to cost center after status FULL in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |