- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Automation of Actual Costing Run (CKMLCP) in Mater...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction:

In Material ledger, Actual Cost calculation is an important part, which includes multiple steps that need to be executed by the business controllers. These steps include production/process order closing, overhead cost calculation, execution of assessment/distribution or indirect activity allocation cycles, actual cost split, actual activity price calculation and the most important CKMLCP execution in material ledger.

CKMLCP includes multiple steps that took many hours to get executed. If we take an example of a MNC organization presence all over the world, then execution of period end closing took more than 10 to 15 hours. In this document, I will explain how we can atomize the execution of CKMLCP and reduce the execution of time.

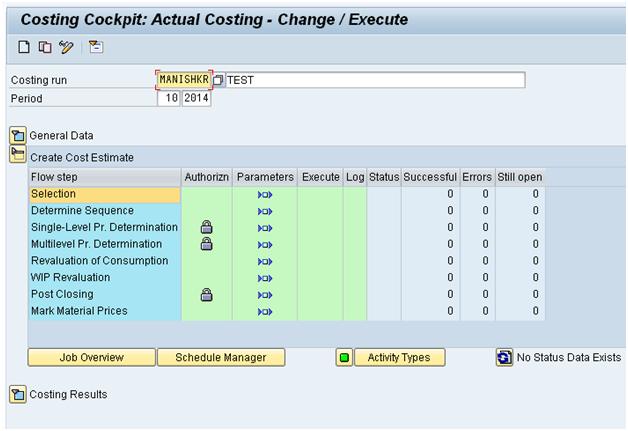

Period End Closing CKMLCP Overview:

CKMLCP is executed to calculate Period Unit Price (PUP), which basically represent average actual cost for material or semi finished goods. Execution of CKMLCP includes the below steps:

I. Selection

II. Determine Sequence

III. Single level price determination

IV. Multilevel price determination

V. Revaluation of consumption

VI. WIP revaluation

VII. Post closing

VIII. Mark material price

Define the costing run name and period in transaction CKMLCP

Select all the plants for at General data and save the costing run.

Now click on Parameters of each steps (for selection, determine sequence, Single –level, multilevel etc.), define the parameters criteria and save the variant.

Selection:

Execution of Selection steps identified, the list of materials for which the Periodic Unit Price calculation need to be executed during CKMLCP. The selection step work on the below concept:

Ø Selection of all the materials for those plants specified at creation of CKMLCP costing run

Ø It includes the list of materials for which any goods movement happened during the current period or any of the previous periods after the go-live off plant in Material ledger

Ø The material for which ML active indicator is done material master

Ø Material with status other than not defined or new.

Click on change parameter for selection step:

Select background processing and Save log, click on Save button to save the variant. Note down the variant name (it will be same in all the other steps under the same costing run in CKMLCP for a single period). Don`t need to execute the steps now.

Determining Sequence:

Execution of this step determines the sequence of materials in which the actual cost needs to be calculated for those materials.

It determine the group of materials, the cost of which don`t depend the cost of any other materials. Generally these are externally procured materials from external vendor (not from internal organization transfer, or purchase from some other plant of same company). These materials are considered for actual PUP calculation at single level price determination. All the other materials, manufacture in-house, sub-contracting, purchase from some other affiliates in the same company are considered for multilevel price determination.

Click on change parameter for determining sequence step

Select background processing and Save log, click on Save button to save the variant.

Single level price determination:

In this step system calculate a single level periodic unit price based on:

Ø Standard price of single level materials

Ø Considering the variances (single level price variance, exchange rate difference)

Ø External or internal group purchase price and landing and nationalization cost variance, etc

Single level price determinations mainly do the price calculation for material procurement type F (external procurement).

Allow Single & Multilevel: Click on authorization and allow single and multilevel price determination

Click on change parameter:

Select Treating materials already processed to process again or don`t process. Select the other criteria as specified in below screen short. Save the variant

Multilevel price determination:

In this step system do the PUP price calculations by considering the below prices:

Ø Variance between the Standard price of raw materials with the Single level PUP calculated at single level price determination

Ø Variance between Plan activity rate with Actual activity rate

Ø Variance allocation performed through the actual flow of goods on actual quantity

Ø Variance between inter-plant (under same company, may or may not be under the same co. codes) transfer are also consider if any goods movement happened between these plants, otherwise not

Ø All other variances having an impact on lower level materials actual cost are consider for calculating actual PUP for higher level materials.

Click on change parameter for multilevel price determination:

Select Treating materials already processed to process again or don`t process. Select the other criteria as specified in below screen short. Save the variant

Revaluation of consumption:

In this step system do the revaluations of all the consumption based on the actual PUP calculated at single level or multilevel price determination. The main purpose of this step is to bring the cost of consumption to actual cost, so that the profit margins are not over or under stated.

Click on change parameter for revaluation step:

Select Treating materials already processed to process again or don`t process. Select the other criteria as specified in below screen short. Save the variant

WIP revaluation:

In this step system do the revaluations of all the Work in progress based on the actual PUP calculated at multilevel price determination.

Click on change parameter for WIP revaluation step

Select Treating materials already processed to process again or don`t process. Select the other criteria as specified in below screen short. Save the variant

Post closing:

At post closing step, system do the posting of all the variances calculated during single level or multilevel price determination and do the revaluation of consumption and closing inventory, and passed the necessary entries.

Allow Post closing: Click on authorization and allow post closing for the current period

Click on change parameter for Post closing step

Select processing type as Execute; Select the other criteria as specified in below screen short. Save the variant.

Mark material price

Material ledger provides the functionality of converting the current Periodic unit Price (PUP) as standard cost of next month. This can be done via executing the Mark material price step.

After executing this step, the PUP of current months gets updated as marked cost estimate for coming month. For converting, the PUP of current month as standard cost of next month, we need to activate Dynamic price release.

Click on change parameter for Mark material price step:

Select the other criteria as specified in below screen short. Save the variant.

Don’t execute any steps while changing the step; if we execute the steps at that point of time, then we need to wait for first step to get executed to start the next step.

Automation of steps for CKMLCP

All the steps for CKMLCP can be executed in one step by designing the process flow with the help of background job schedule.

Now Automate through job runs with the programs used for executing all the different steps. In the below table I have mentioned the name of program used for executing the steps by SAP. We can used the name of program specified in the below table

Transaction SM36

Define the background job, click enter

Now at step 1: define the details for selection steps.

Click on Save

Now click on new step and at step 2, define the details of determine sequence:

Click save

In the same way define all the steps in the right order.

Till the step 6, the details will be:

Define for the remaining two and execute the background job run.

Define the jobs to start immediate and save the variant. After finishing the jobs, if there are no errors, we can check that all the steps for CKMLCP get executed successfully.

The same type of processes can be used to atomize the different costing process (like CK40N) without any complex development. This will result saving lot of time.

- SAP Managed Tags:

- FIN Controlling

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- How can I Copy Material Master in S/4HANA Public Cloud? in Enterprise Resource Planning Q&A

- Change material cost in Sales return process during PGR in Enterprise Resource Planning Q&A

- CK40N costing level doesn't show materials costed without errors in Enterprise Resource Planning Q&A

- CK40N CK24 CK11N COSTING RUN in Enterprise Resource Planning Q&A

- How to process bulk quantity purchase order if the material is dynamic in nature. in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |