- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- An alternative for Equipment Calibration in Asset ...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Calibration is the process by which instrumentation, gauges, meters, and other testing equipment are set up, checked, and maintained to ensure they continue to give accurate, precise, reliable results. A huge range of equipment including manufacturing instruments, devices and gauges can require calibration.

This is an important process under plan maintenance to calibrate test equipment and take appropriate measures based on the results.

As we are aware that in SAP S/4HANA Cloud, Public edition the calibration scope item is not yet available as a standard scope item and this blog post explains an alternative to simple equipment calibration process with limitations.

Assumptions:

- No standard calibration scope item available yet

- No PM-QM integration (MICs/Inspection point/type)

- No inspection lot creation

Here we are using measuring point as calibration parameters whereas the respective measurement document serves as readings for each calibration.

Below is the process flow for the calibration process.

Process Flow

The prerequisite data would be as follows-

- Measuring Point for the test equipment

- Maintenance Task List

- Maintenance Plan

The process starts with the need for calibration for the test equipment with the task list comprising of the steps for calibration and parameters that must be calibrated, vendor details in case of external calibration.

This continues with a maintenance plan for the test equipment with time based single cycle or strategy plan where the equipment must be calibrated at regular/ defined intervals.

So once the maintenance plan is scheduled, there is a due calibration order generated as per the cycle length and scheduling parameters defined in the maintenance plan.

As we know that there is no feasibility to configure order type in SAP S/4HANA Cloud public edition, we can leverage maintenance activity type on the maintenance order to specify calibration activity/internal calibration/external calibration.

Maintenance Order

Similarly on the Equipment master we can use Sort field/Class and characteristics/Custom field to specify the test equipment as we cannot configure equipment categories.

So once the calibration order is generated, the execution remain the same as for any preventive /proactive order with a step of capturing measurement document for measuring point for the test equipment during the Execution phase via Perform Maintenance Jobs app.

Please note that Recording measurements from Perform Maintenance Job shall not create notifications based on condition. If customers wish to do that, they must record the readings from the app Create Measurement Document (IK11)

Perform Maintenance Jobs

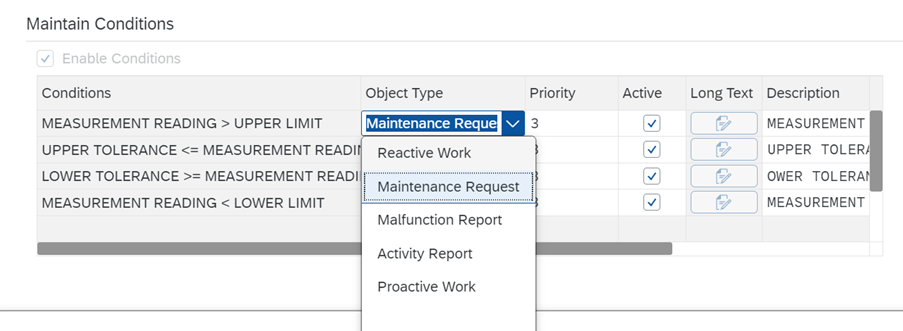

Measuring point can be also configured to accommodate various conditions based on which the deviation notifications can be raised in case the reading goes above upper limit/tolerance or below lower limit/tolerance etc.

Measuring Point Conditions

For Internal calibration the labor hours can be captured by recording time spent and for External calibration, service can be added to the maintenance order, which creates a PR, converted to PO and completed with Service entry sheet. (Standard lean services). For external calibration, the vendor certificate can be attached to the calibration order and process can be completed with technically completing the order.

We can utilize app Change measurement documents to look at the measurement document created as a part of maintenance order.

Change Measurement Documents

To summarize, this way we can use the above process as a workaround for the calibration process in current SAP S/4HANA Cloud, public edition.

We still do not have the fixed timeline on when the calibration scope item will be delivered in SAP S/4HANA cloud, public edition but we can leverage this workaround meanwhile.

Thanks for your time and please share your valuable feedback and inputs in a comment below. Also kindly follow the tag SAP S/4HANA Cloud for Asset Management to watch similar content.

You can also post your questions at All Questions in SAP S/4HANA Cloud for Asset Management | SAP Community

- SAP Managed Tags:

- SAP S/4HANA Cloud for Asset Management,

- SAP S/4HANA Cloud Public Edition

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

33 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

32 -

Expert Insights

114 -

Expert Insights

202 -

General

2 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

413 -

Life at SAP

2 -

Product Updates

4,680 -

Product Updates

281 -

Roadmap and Strategy

1 -

Technology Updates

1,496 -

Technology Updates

113

- SAP Public Cloud Credit Management VKM4/VKM5 alternative solution? in Enterprise Resource Planning Q&A

- How to Handle VMI on Subcontracted Assemblies in Enterprise Resource Planning Q&A

- SAP Fiori for SAP S/4HANA – Trial system options for Private Cloud and On-Premise in Enterprise Resource Planning Blogs by SAP

- advanced payment management: Processing Inbound Messages (PAIN.002) using Multi-Bank Connectivity in Enterprise Resource Planning Blogs by SAP

- 4 Expert Tips for Setting Up the Organizational Structure in SAP Central Business Configuration in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 13 | |

| 6 | |

| 5 | |

| 5 | |

| 5 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 2 |