- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- How Swiss Federal Railways Reshaped Asset Manageme...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-10-2019

11:51 AM

Today at Sapphire, I dropped into a session to hear from Urs Gehrig, Senior Consultant at Swiss Federal Railways SBB, the national railway company of Switzerland. Urs explained how Swiss Federal has successfully implemented reliability-centered maintenance (RCM) processes for its trains by empowering its workforce to access information in real time and predict potential operational problems ahead of time.

The focus of reliability-centered maintenance is, of course, reliability. On a daily basis, Swiss Federal transports 1.25 million passengers on more than 6,000 trains. Keeping these trains running in a reliable fashion is a top priority.

To get the job done, Swiss Federal powers its RCM processes with SAP Intelligent Asset Management solutions. Specialist technical knowledge is pooled across disciplines and mixed with operational context. The result is RCM analysis based on comprehensive data – and a fully justified maintenance file presented in a standardized format.

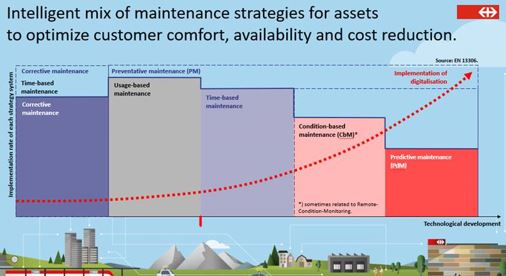

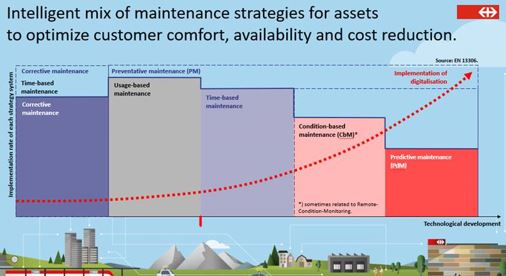

RCM, of course, is hardly a new idea in asset management. What separates Swiss Federal is an intelligence mix of asset maintenance strategies to optimize customer comfort, availability and cost reduction.

One key strategy is predictive maintenance – enabled in part by incoming diagnostic data regarding cycle, temperature, pressure, and other asset-related KPIs. Such data helps Swiss Federal transcend costly “run-to-failure” strategies with feedback loops that identify failure modes, associated risks, and countermeasures required.

Digitization and proper data management are critical for making all of this happen. After all, the more you digitize, the more data you have available, and the more you can move to predictive maintenance practices.

With SAP Intelligent Asset management, Swiss Federal has defined a vehicle structure that allows for pervasive data integration – from the vehicle fleet level down to the bill of materials for individual assets.

Based on a solid asset data foundation, Swiss Federal is also moving toward creating sophisticated digital representations (digital twins) of each asset in SAP Asset Intelligence Network (AIN) – with links to the failure-modes of parts to improve failure discovery.

With on-board vehicle monitoring systems, the company also collects conditional coupling cycle data. It then adds this data to SAP Predictive Maintenance and Service (PdMS) to build rule-sets. What are these rule sets used for? To automatically generate maintenance notifications – based on operational context – for staff to take action as required.

RCM. Predictive maintenance. Networked digital twin technology with automated maintenance notifications. Quite sophisticated! I wonder what’s coming next for Swiss Federal.

Learn more about SAP Intelligent Asset Management and register for the ARC whitepaper, Intelligent Asset Management improves asset performance.

The focus of reliability-centered maintenance is, of course, reliability. On a daily basis, Swiss Federal transports 1.25 million passengers on more than 6,000 trains. Keeping these trains running in a reliable fashion is a top priority.

To get the job done, Swiss Federal powers its RCM processes with SAP Intelligent Asset Management solutions. Specialist technical knowledge is pooled across disciplines and mixed with operational context. The result is RCM analysis based on comprehensive data – and a fully justified maintenance file presented in a standardized format.

Turning “run to failure” into “run to success”

RCM, of course, is hardly a new idea in asset management. What separates Swiss Federal is an intelligence mix of asset maintenance strategies to optimize customer comfort, availability and cost reduction.

One key strategy is predictive maintenance – enabled in part by incoming diagnostic data regarding cycle, temperature, pressure, and other asset-related KPIs. Such data helps Swiss Federal transcend costly “run-to-failure” strategies with feedback loops that identify failure modes, associated risks, and countermeasures required.

Digitization and proper data management are critical for making all of this happen. After all, the more you digitize, the more data you have available, and the more you can move to predictive maintenance practices.

With SAP Intelligent Asset management, Swiss Federal has defined a vehicle structure that allows for pervasive data integration – from the vehicle fleet level down to the bill of materials for individual assets.

Based on a solid asset data foundation, Swiss Federal is also moving toward creating sophisticated digital representations (digital twins) of each asset in SAP Asset Intelligence Network (AIN) – with links to the failure-modes of parts to improve failure discovery.

With on-board vehicle monitoring systems, the company also collects conditional coupling cycle data. It then adds this data to SAP Predictive Maintenance and Service (PdMS) to build rule-sets. What are these rule sets used for? To automatically generate maintenance notifications – based on operational context – for staff to take action as required.

RCM. Predictive maintenance. Networked digital twin technology with automated maintenance notifications. Quite sophisticated! I wonder what’s coming next for Swiss Federal.

Learn more about SAP Intelligent Asset Management and register for the ARC whitepaper, Intelligent Asset Management improves asset performance.

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Named a Leader in the 2024 Gartner Magic Quadrant for Transportation Management Systems in Supply Chain Management Blogs by SAP

- Control cycle for EWM IM managed slocs in Supply Chain Management Q&A

- Preferred Alternative UoM for Warehouse Operation in EWM in Supply Chain Management Blogs by Members

- SAP ATTP in Supply Chain Management Q&A

- Manage Analytics App- How to change data model to custom PA from Best Practices Pa- SAPIBP1 in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 8 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |