- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- ERP Post Implementation Challenges – Part 2 Reconc...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

In my previous blog "ERP Post Implementation Challenges’ - Part 1" I have explained the concept of COGM, COGS and deriving the closing stock. In this blog I will be concentrating on the Reconciling GL, Raw Material Consumption, Semi Finished / Finished Goods Production and Vendor Invoice.

Let me divide the topic into;

Reconciliation 1:

Opening Stock + Raw Material Receipt - Raw Material Consumed = Raw Material Closing Stock

Reconciliation 2:

Receipt of Raw Material = Invoice received from Vendor

Reconciliation 3:

Raw Material Consumed = Raw Material Issued for the Production of Finished Good

= Raw Material Consumption GL

Reconciliation 4:

Raw Material Closing Stock = Stock GL of Raw Material

Now let us analyze each scenario;

Reconciliation 1: Opening Stock + Raw Material Receipt - Raw Material Consumed = Raw Material Closing Stock

As explained in my Previous Blog "ERP Post Implementation Challenges’ - Part 1" all material movements should be considered for calculating the closing stock of material.

Reconciliation2: Receipt of Raw Material = Invoice received from Vendor

The Raw Material received should be matching with the invoice received from the vendors. I have done quite a lot of research to generate report on the list of invoices received against a material.

Material Receipt (MB5B) with movement type 101+102 = Stock GL of Raw Material + Price Diff GL of Raw Material with Type "WE"

To find the list of Invoice generated against the Raw Material:

There can be invoice and Credit/Debit notes posted against the material.

To generate Invoice list generated against the material:

We have to combine few tables for generating the report.

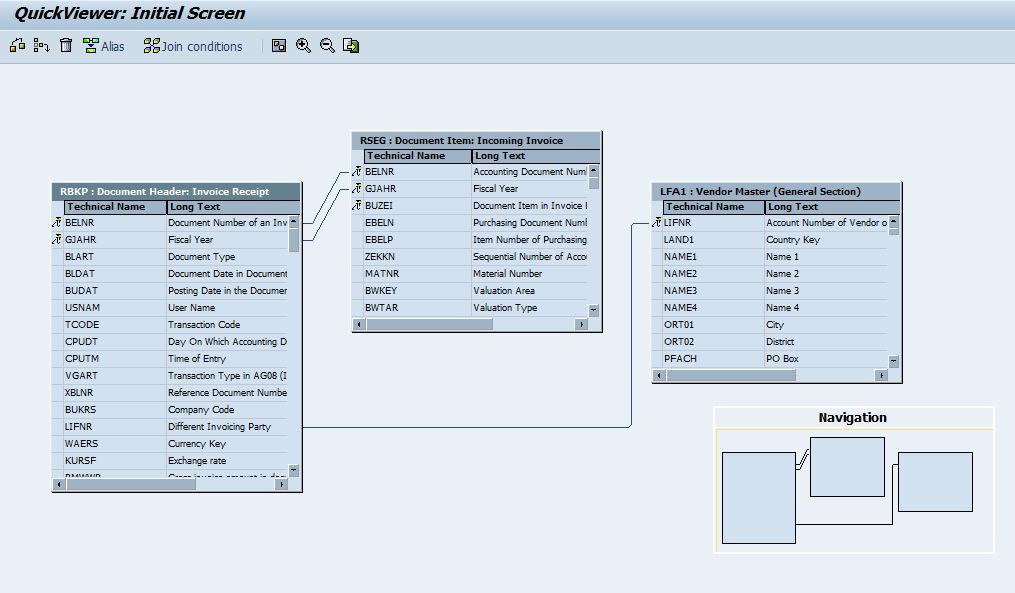

Execute SQVI and create a query with the following data.

Tables: RBKP, RSEG, LFA1

Joining Condition:

Tables RBKP-RSEG -> Joining Fields BELNR,GJAHR

Tables RBKP-LFA1 -> Joining Fields LIFNR

Figure 1.0

Figure 2.0

To generate Credit Note / Debit Note list generated against the material:

We have to combine few tables for generating the report.

Execute SQVI and create a query with the following data.

Tables: RBKP, RBMA, LFA1

Joining Condition:

Tables RBKP-RBMA -> Joining Fields BELNR,GJAHR

Tables RBKP-LFA1 -> Joining Fields LIFNR

Figure 3.0

Figure 4.0

Debit / Credit will be recorded as "S" or "H"

Reconciliation 3: Raw Material Consumed = Raw Material Issued for the Production of Finished Good = Raw Material Consumption GL

Raw Material will be consumed for the production of Semi / Finished Good, which will be created against Process Order. The total raw material consumed against a process order can be generated from transaction code KOB1.

Let me explain with an example:

Raw Material 1 (RM1) is used for the production of three Finished Good (FG1, FG2, FG3)

| Material | Process Orders | Quantity Produced |

|---|---|---|

| FG1 | 10000035 | 67,981.00 |

| FG2 | 11000035 | 343,842.00 |

| FG3 | 12000035 | 61,601.00 |

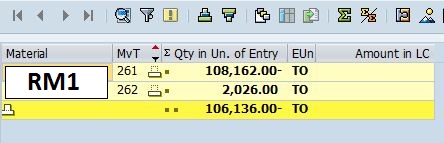

Total Raw Material RM1 issued during the period is 106,136.00 TO. This is the quantity used for then production of 473,424.00 TO of FG1, FG2, FG3.

Table 1.0

(Report from MB51 movement Type 101 + 102)

From transaction KOB1 we will be able to equate the Finished Good Produced and Raw Material Consumed quantity.

Figure 6.0

Figure 7.0

Raw Material (RM1) Consumption GL should be updated with the value of 1,061,360.00

(Report from FBL3N Raw Material (RM1) Consumption GL + Raw Material (RM1) Price Difference GL)

Fugure 8.0

GL Entries Posted During the Process;

Raw Material Consumed for Production of Finished Good

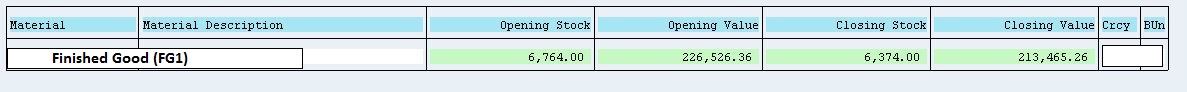

Reconciliation 4: Closing Stock = Stock GL of Material

Generate Closing Stock report for Material from MB5B

Figure 9.0

Stock Report of Material From FBL3N

Figure 10.0

Generally We can reconcile opening, receipt, issue Closing by inputting values in the table listed below;

| Material | Opening | 0 Qty | Mat Receipt (101+102) | Price Revaluvation | MIR7 | Issue To Production Order 261 + 262 | Issue To Cost Center 201 + 202 | Physical Inventory Posting | GL Consumption | Sales | Closing |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | |

| FG1 | A | B | C | D | E | F | G | H | D+E+F+G+H | J | (A+B+C+D) - (F+G+H+J) |

| 1,683,916.80 | 54,700.53 | 7,539,313.34 | 256,027.28 | 670.28 | 7,543,679.84 | 0.00 | 0.00 | 7,800,377.40 | 161,430.24 | 1,828,847.87 |

Table 2.0

0 Quantity - Execute Transaction MB5B. Sort Based on Movement Type

0 Quantity Included Price Revaluation & MIR7 entries

0 Qty of FG1 Entry:

0 Qty Other = 54,700.53 +

Price Revaluation = 256,027.28

0 Qty -> 310,727.81

Figure 11.0

| Debit | Credit | |

|---|---|---|

| Raw Material Consumption | XXX | |

| Stock of Raw Material | XXX | |

| Stock of Finished Good 1 (FG1) | XXX | |

| COGM of Finished Good 1 (FG1) | XXX |

Table 3.0

Important Transaction Codes:

| Transaction Code | Description |

|---|---|

| MB5B | Material Report |

| MB51 | Material Report |

| FBL3N | GL Report |

| FBL1N | Vendor Report |

| KOB1 | Production Report |

| MCBE | Material Report |

| MC.A | Material Report |

| MC+E | Sales Report |

| SQVI | Dynamic Query |

Table 4.0

- SAP Managed Tags:

- Mill Products,

- Public Sector,

- SAP ERP,

- FIN (Finance)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Update of the SAP Activate Roadmap for SAP S/4HANA (on prem) upgrades with the Clean Core Strategy in Enterprise Resource Planning Blogs by SAP

- SAP Signavio Process Navigator turning 1-year old today! in Enterprise Resource Planning Blogs by SAP

- implementation partner is different and license partner different SAP B1 in Enterprise Resource Planning Q&A

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

- Flexible Forecast consumption BADI not working in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 |