- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Product Management Update: SAP #S4HANA Cloud 1802 ...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-14-2018

6:53 PM

This blog provides you an overview of innovations in our SAP S/4HANA Cloud 1802 release for Manufacturing. Please check out also the video from my colleague Parvathy Sankar.

First and foremost, we have great enhancements in the area of Demand Driven Replenishment, which we’ve brought out during the last two releases. With 1802, we have now received the compliance certification from the Demand Driven Institute. The Institute has certified that SAP S/4HANA Cloud has enough capabilities to implement, sustain and even improve a DDMRP implementation.

Fig. 1: Compliance Certification from the Demand Driven Institute

Demand-driven replenishment helps the production planner to plan and manage supply chains efficiently based on customer demand, rather than through traditional MRP procedures. You do this by strategically decoupling material flows, and by maintaining lower inventory using dynamically-managed buffer (stock) levels for relevant products.

Decoupling material flows at strategic locations can help avoid the so called ‘Bullwhip Effect’, which refers to increasing swings in inventory along the supply chain in response to changes in customer demand. To find out more about the Bullwhip Effect, please visit this use case blog.

Keeping in line with this theme, we bring out a few changes along our demand-driven capabilities. Demand-driven replenishment forms the basis for a reliable material flow, by defining buffers at strategically important points and adjusting these buffers regularly.

A well-balanced buffer level for relevant products ensures they are sufficiently stocked to prevent excessive storage costs or losses without running out of demand. We use buffer positioning to classify products based on value of goods, usage and variations in demand, and buffer sizing to classify products based on decoupled lead time. The main innovations here are the ability to have planned adjustment factors and time-dependent (future) buffer levels.

Fig. 2: SAP Fiori app ‘Manage Buffer Levels’

We now have a new end-to-end process for Demand-Driven Replenishment Planning and Execution. With our Replenishment Planning, you can review the replenishment planning status of buffered components. Additionally, you can create demand or supply for buffered components after the planning status has changed. With replenishment execution, you can review the replenishment execution status of buffered components after converting supply into production execution. Thus, you can reduce on-hand stock to stimulate replenishment need or expedite supply and run production execution.

Quicker confirmation in production progress is very important to avoid showstoppers in the process. The new intuitive SAP Fiori app “Confirm Production Operation” simplifies the execution of production orders. This app improves the usability of recording the production progress and empowers the production operator to quickly

Fig. 3: Intuitive SAP Fiori app “Confirm Production Operation”

The SAP Fiori app “Manage Production Orders” enables the production supervisor to easily monitor the progress of operation.

Fig. 4: Monitor the progress of operation with the SAP Fiori app “Manage Production Orders”

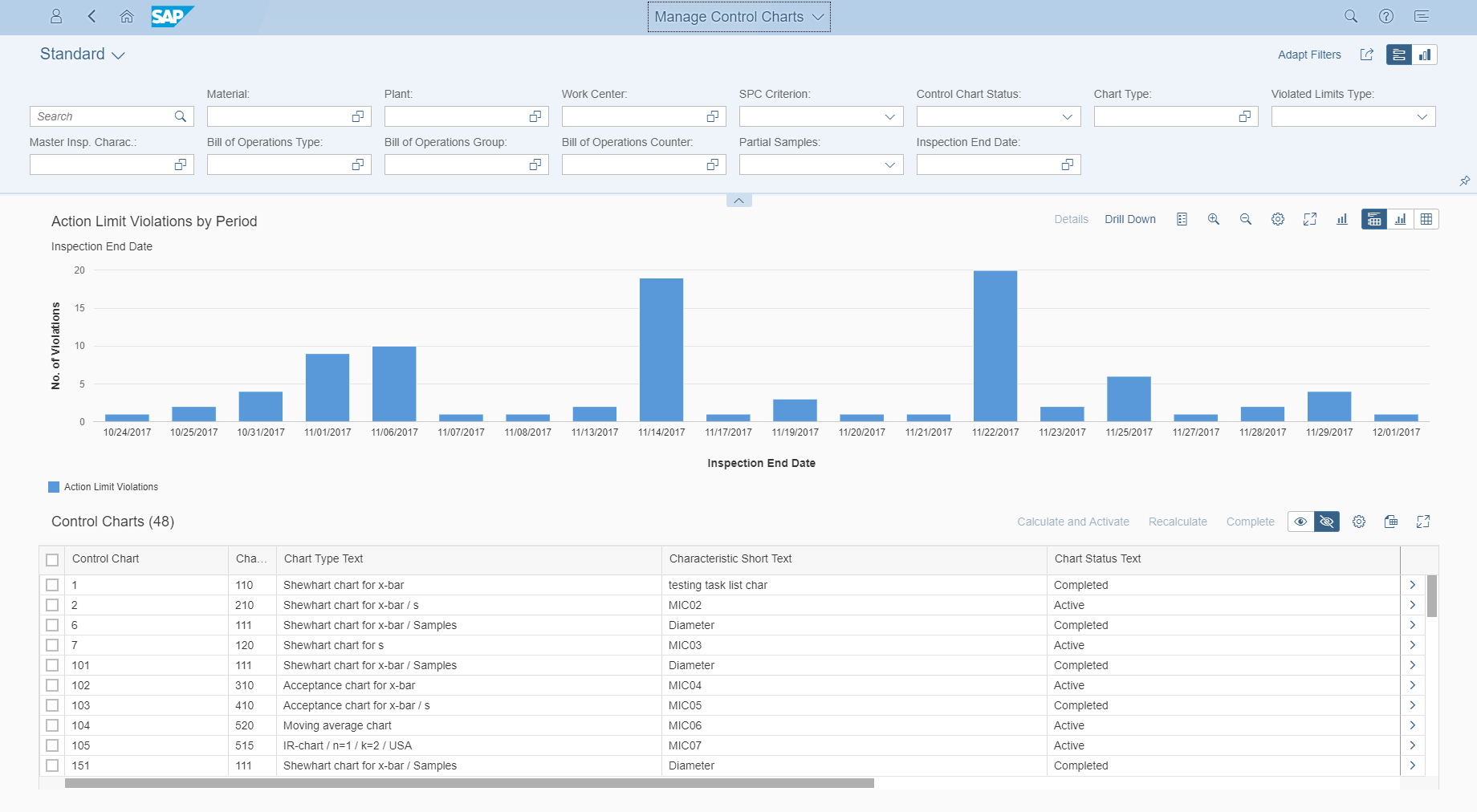

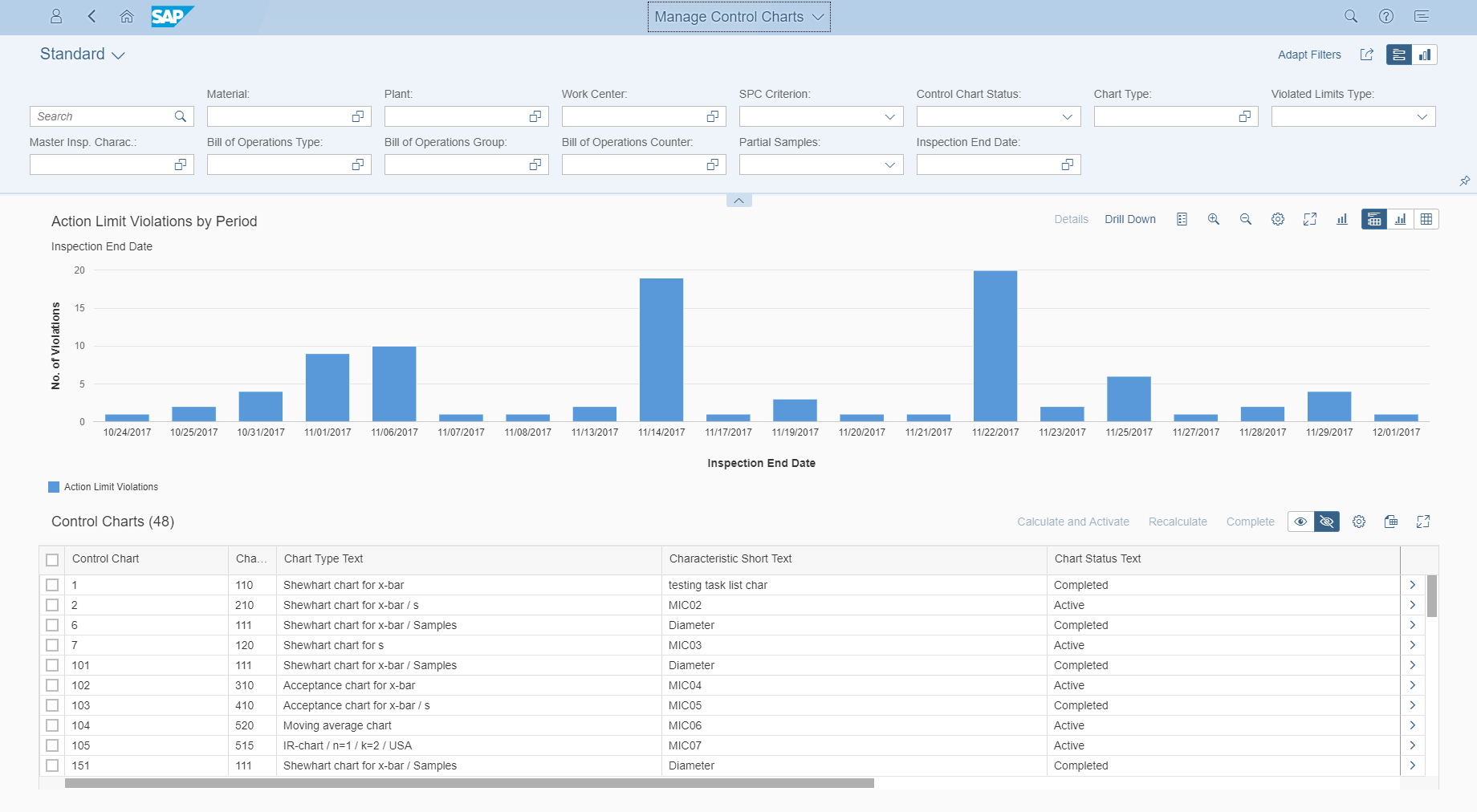

In Quality Management, we have introduced the ability to record results during production on a regular basis. Quality engineers can now use statistical process control and its most important tool, the quality control chart to monitor and control the quality of production processes.

Fig. 5: SAP Fiori app “Manage Control Charts”

Furthermore, I want to highlight the new SAP Fiori app “Record Results for Inspection Points” which enables quality technicians to easily process inspections during a production operation.

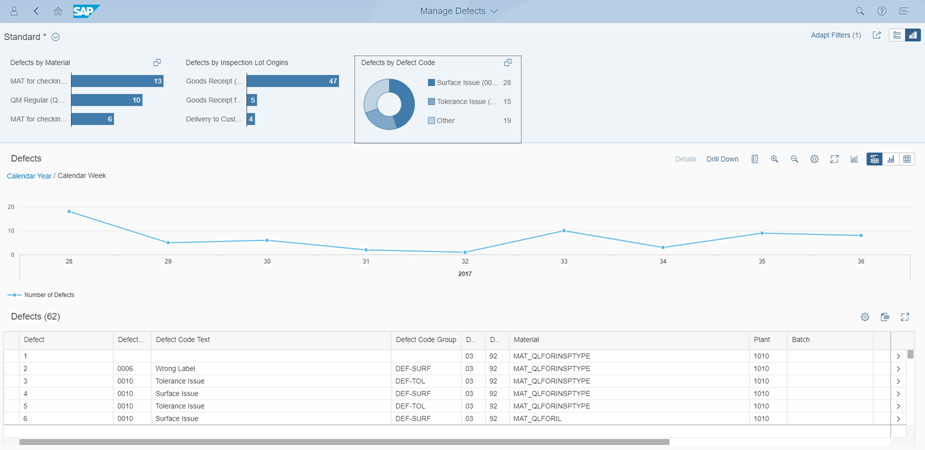

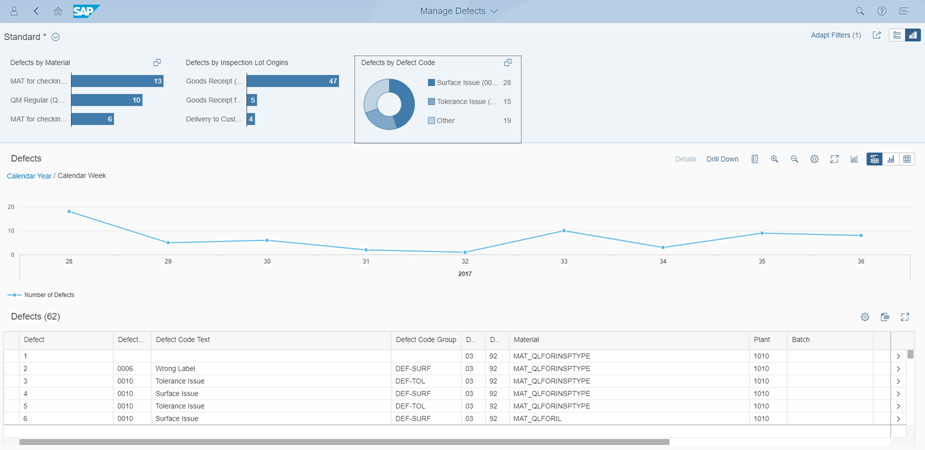

Moreover, we are introducing defect handling in the area of quality management. Quality technicians and engineers can create a defect and quality planners and engineers can easily monitor and manage defects which have been created during the inspection process.

Fig. 6: SAP Fiori app “Manage Defects”

In the area of inventory management let me share a really intelligent innovation with you, the prediction of shipment dates.

For companies issuing and receiving goods from and to their plants, it is important to track the status of the materials in transit in order to take action in case of problems. The "Overdue Materials – Stock in Transit” app gives an overview on the status of the shipment allowing the business user to take action.

What can inventory managers do to directly get predictive insights, and to make better and faster decisions? The answer is: leverage our iERP.

With Predictive Analytics integrator (PAi) we are enhancing the app "Overdue Materials – Stock in Transit” with ‘Predicted Shipment Dates’. The system analyzes whether a purchase order item will be delayed and displays the predicted delivery date. Based on historical data the system tries to predict whether the stock in transit order item will be delayed which enables the inventory manager to identify and manage delivery delays in time.

Each predictive model is customer specific. An analytics specialist has to train the model first on the customer’s own historical data before it can start to produce predictive scores. The inventory manager will then be able to check the information so that he/she is able to adjust time scheduling and plan more effectively.

Fig. 7: SAP Fiori app ‘Overdue Materials – Stock in Transit’

In case you want to learn more about predictive analytics for stock in transit with SAP S/4HANA & SAP Leonardo, watch this video on YouTube.

Last but not least, I want to indicate further innovations like the integration of Advanced Variant Configuration into the sales quotation and the third-party warehouse management system integration which enables the integration of self-operated warehouses implemented with third-party warehouse management solutions to SAP S/4HANA Cloud.

Production Planning and Execution

Demand-Driven Replenishment

First and foremost, we have great enhancements in the area of Demand Driven Replenishment, which we’ve brought out during the last two releases. With 1802, we have now received the compliance certification from the Demand Driven Institute. The Institute has certified that SAP S/4HANA Cloud has enough capabilities to implement, sustain and even improve a DDMRP implementation.

Fig. 1: Compliance Certification from the Demand Driven Institute

Demand-driven replenishment helps the production planner to plan and manage supply chains efficiently based on customer demand, rather than through traditional MRP procedures. You do this by strategically decoupling material flows, and by maintaining lower inventory using dynamically-managed buffer (stock) levels for relevant products.

Decoupling material flows at strategic locations can help avoid the so called ‘Bullwhip Effect’, which refers to increasing swings in inventory along the supply chain in response to changes in customer demand. To find out more about the Bullwhip Effect, please visit this use case blog.

Keeping in line with this theme, we bring out a few changes along our demand-driven capabilities. Demand-driven replenishment forms the basis for a reliable material flow, by defining buffers at strategically important points and adjusting these buffers regularly.

A well-balanced buffer level for relevant products ensures they are sufficiently stocked to prevent excessive storage costs or losses without running out of demand. We use buffer positioning to classify products based on value of goods, usage and variations in demand, and buffer sizing to classify products based on decoupled lead time. The main innovations here are the ability to have planned adjustment factors and time-dependent (future) buffer levels.

Fig. 2: SAP Fiori app ‘Manage Buffer Levels’

We now have a new end-to-end process for Demand-Driven Replenishment Planning and Execution. With our Replenishment Planning, you can review the replenishment planning status of buffered components. Additionally, you can create demand or supply for buffered components after the planning status has changed. With replenishment execution, you can review the replenishment execution status of buffered components after converting supply into production execution. Thus, you can reduce on-hand stock to stimulate replenishment need or expedite supply and run production execution.

Record and manage the production progress

Quicker confirmation in production progress is very important to avoid showstoppers in the process. The new intuitive SAP Fiori app “Confirm Production Operation” simplifies the execution of production orders. This app improves the usability of recording the production progress and empowers the production operator to quickly

- confirm production operations partially or completely

- report produced quantities between batches

- report durations for the activities for selected production operations

- record yield and scrap

- record component consumption

Fig. 3: Intuitive SAP Fiori app “Confirm Production Operation”

The SAP Fiori app “Manage Production Orders” enables the production supervisor to easily monitor the progress of operation.

Fig. 4: Monitor the progress of operation with the SAP Fiori app “Manage Production Orders”

Quality Management

Statistical process control to monitor and control production processes

In Quality Management, we have introduced the ability to record results during production on a regular basis. Quality engineers can now use statistical process control and its most important tool, the quality control chart to monitor and control the quality of production processes.

Fig. 5: SAP Fiori app “Manage Control Charts”

Furthermore, I want to highlight the new SAP Fiori app “Record Results for Inspection Points” which enables quality technicians to easily process inspections during a production operation.

Defect Handling

Moreover, we are introducing defect handling in the area of quality management. Quality technicians and engineers can create a defect and quality planners and engineers can easily monitor and manage defects which have been created during the inspection process.

Fig. 6: SAP Fiori app “Manage Defects”

Inventory Management

SAP Predict Arrival of Stock in Transit

In the area of inventory management let me share a really intelligent innovation with you, the prediction of shipment dates.

For companies issuing and receiving goods from and to their plants, it is important to track the status of the materials in transit in order to take action in case of problems. The "Overdue Materials – Stock in Transit” app gives an overview on the status of the shipment allowing the business user to take action.

What can inventory managers do to directly get predictive insights, and to make better and faster decisions? The answer is: leverage our iERP.

With Predictive Analytics integrator (PAi) we are enhancing the app "Overdue Materials – Stock in Transit” with ‘Predicted Shipment Dates’. The system analyzes whether a purchase order item will be delayed and displays the predicted delivery date. Based on historical data the system tries to predict whether the stock in transit order item will be delayed which enables the inventory manager to identify and manage delivery delays in time.

Each predictive model is customer specific. An analytics specialist has to train the model first on the customer’s own historical data before it can start to produce predictive scores. The inventory manager will then be able to check the information so that he/she is able to adjust time scheduling and plan more effectively.

Fig. 7: SAP Fiori app ‘Overdue Materials – Stock in Transit’

In case you want to learn more about predictive analytics for stock in transit with SAP S/4HANA & SAP Leonardo, watch this video on YouTube.

Process Integration

Last but not least, I want to indicate further innovations like the integration of Advanced Variant Configuration into the sales quotation and the third-party warehouse management system integration which enables the integration of self-operated warehouses implemented with third-party warehouse management solutions to SAP S/4HANA Cloud.

For more information on SAP S/4HANA Cloud, check out the following links:

- Sven Denecken’s SAP S/4HANA Cloud 1802 Release Blog

- SAP S/4HANA Cloud release info: http://www.sap.com/s4-cloudrelease

- Best practices for all the cloud editions here

- What’s New in SAP S/4HANA Cloud 1802 document

- SAP Managed Tags:

- SAP S/4HANA Public Cloud

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

22 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

156 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud, public edition, ABAP Environment Case 8: Material Shelf Life Management in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud ABAP开发案例之八:物料临期管理App in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 8 | |

| 7 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |