- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Mass forecasting in SOP in Background Mode

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Former Member

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-08-2017

1:25 PM

Mass forecasting in SOP in Background Mode

Please find bellow the procedure in order to perform mass forecasting in background when doing SOP, either standard or flexible (The example described here is on standard SOP).

Here, we define the planning type we are going to use (SOPKAPAM, since we are interested in the individual material itself), the activity (PROGNOSE = forecasting), the forecast profile we are going to use (ZAP – my customized forecasting profile), and the name of the entity field we want to forecast (ABSAT = SALES).

Press Execute

We enter the name of the infostructure and the specific version we are going to use (here, since we are using standard SOP we will be using S076).

Press Execute and choose (by double-click) SOPKAPAM as our planning type

In the next screen, press cancel on the already existing variables in order to create a new one for this specific background job

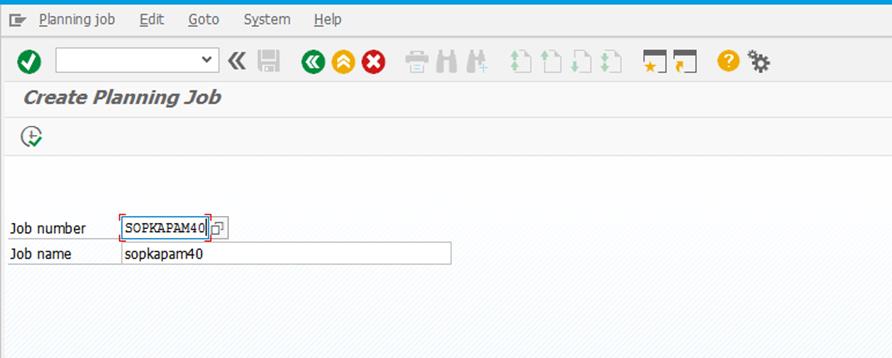

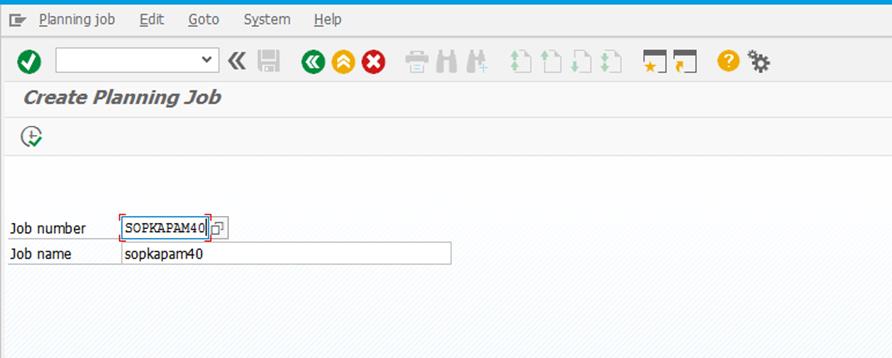

Enter a name and press “Create”

In the next screen, choose “For all selection screens” and press “Continue”

Please note that you can re-use any of the variables you have already created, if it serves your needs. However, the purpose of this example was to illustrate how to define a new variable.

Here, we enter the material we want to forecast, the corresponding plant, the planning activity we are going to use (the one we created earlier in transaction MV8T), and we also set “Plant” as our aggregation level

We press on “Attributes”, and we are getting the following message:

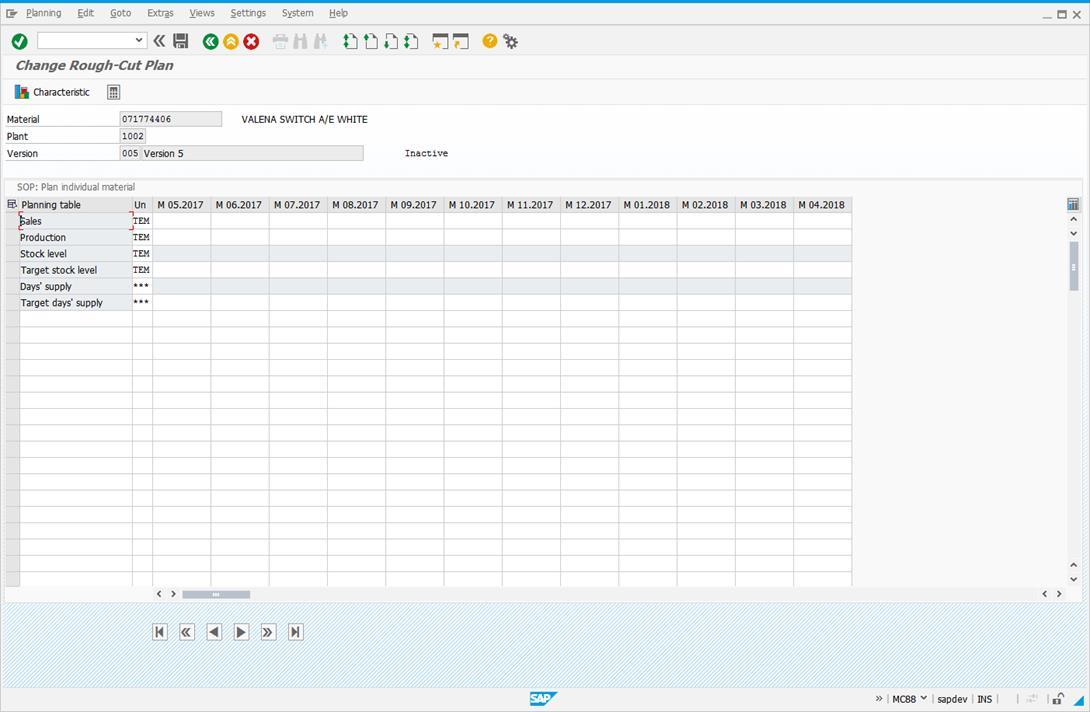

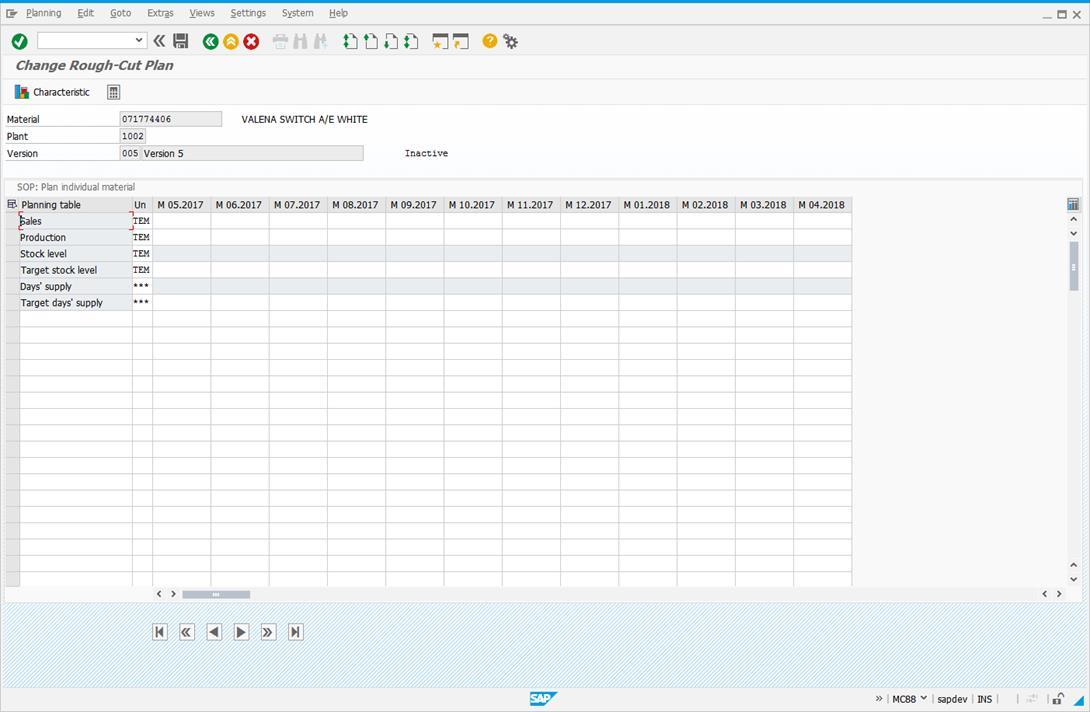

We are getting this message, because version 005 for this material and this planning type has not been created. This means that the forecasting program cannot find where to store its result. For this reason, we terminate the creation of the background job, and we go to MC87 to create version 005 of material 071774406:

We press Enter. In the following table we enter nothing, we just press Save.

Now, we start again the procedure of creating the background job, as it was shown earlier. Now, when we reach the point where we previously had the message “No data exist for chosen selection”, we see that now, when we press “Attributes”, everything is OK

We enter a name for our variant and we press SAVE. We get the message that our variant is saved.

For the purpose of our example, we choose “Immediate”

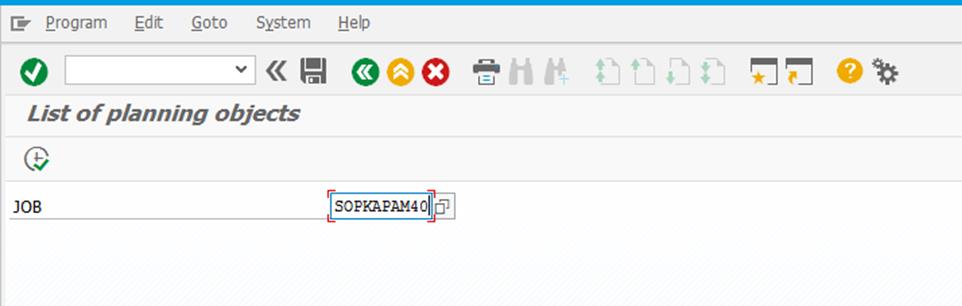

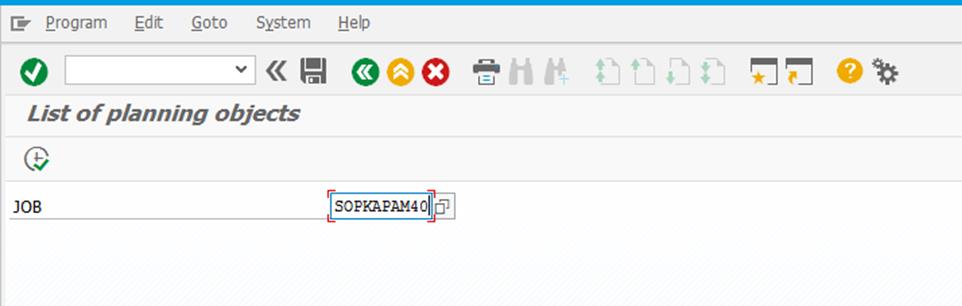

Using transaction MC8J we can check of what happened to our background job

We press execute and we see that our job has run successfully

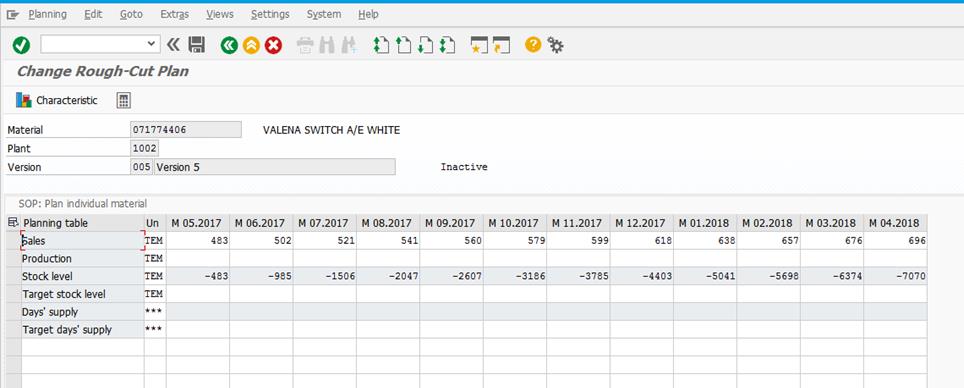

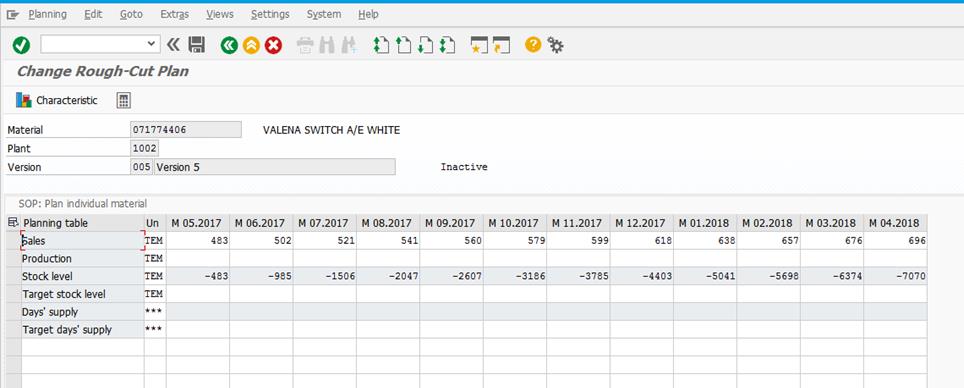

We can further check (that our forecasting has successfully run and created results) by checking version 005 of material 071774406 for plant 1002

You can use this process for any combination of materials, plants and planning activities you wish. However, in order to perform this procedure, you will first have:

Best regards,

Dr. Nikos Giannopoulos

Please find bellow the procedure in order to perform mass forecasting in background when doing SOP, either standard or flexible (The example described here is on standard SOP).

- Define background activity (transaction MC8T)

Here, we define the planning type we are going to use (SOPKAPAM, since we are interested in the individual material itself), the activity (PROGNOSE = forecasting), the forecast profile we are going to use (ZAP – my customized forecasting profile), and the name of the entity field we want to forecast (ABSAT = SALES).

- Create the background job (transaction MC8D)

Press Execute

We enter the name of the infostructure and the specific version we are going to use (here, since we are using standard SOP we will be using S076).

Press Execute and choose (by double-click) SOPKAPAM as our planning type

In the next screen, press cancel on the already existing variables in order to create a new one for this specific background job

Enter a name and press “Create”

In the next screen, choose “For all selection screens” and press “Continue”

Please note that you can re-use any of the variables you have already created, if it serves your needs. However, the purpose of this example was to illustrate how to define a new variable.

Here, we enter the material we want to forecast, the corresponding plant, the planning activity we are going to use (the one we created earlier in transaction MV8T), and we also set “Plant” as our aggregation level

We press on “Attributes”, and we are getting the following message:

We are getting this message, because version 005 for this material and this planning type has not been created. This means that the forecasting program cannot find where to store its result. For this reason, we terminate the creation of the background job, and we go to MC87 to create version 005 of material 071774406:

We press Enter. In the following table we enter nothing, we just press Save.

Now, we start again the procedure of creating the background job, as it was shown earlier. Now, when we reach the point where we previously had the message “No data exist for chosen selection”, we see that now, when we press “Attributes”, everything is OK

We enter a name for our variant and we press SAVE. We get the message that our variant is saved.

- Schedule the background job (transaction MC8G)

For the purpose of our example, we choose “Immediate”

Using transaction MC8J we can check of what happened to our background job

We press execute and we see that our job has run successfully

We can further check (that our forecasting has successfully run and created results) by checking version 005 of material 071774406 for plant 1002

You can use this process for any combination of materials, plants and planning activities you wish. However, in order to perform this procedure, you will first have:

- to create the corresponding plans for the combination of material-plant-version, as we shown earlier in this document. You can do this easily by using an LSMW. In any case, please double-check that the plan/version has been successfully created and saved, otherwise you will continue getting the message “No data exist for chosen selection”, and

- to set specific materials into material filed of the background variable (as we did with material 071774406 earlier). If you do not put any material in this filed in the background variable, the program by default excludes all materials and therefore it produces no result.

Best regards,

Dr. Nikos Giannopoulos

- SAP Managed Tags:

- SAP Sales Cloud

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP IBP: Enhancing Forecast Accuracy with Time Series Analysis and Change Point Detection in Supply Chain Management Blogs by SAP

- UseCase for Pegging- and Cross-Order relationship in SAP S/4HANA Manufacturing for Planning & Scheduling (aka. Production Planning and Detailed Scheduling PP/DS) in Supply Chain Management Blogs by SAP

- EWM Cycle Counting Physical Inventory Procedure in Supply Chain Management Blogs by SAP

- How to Make Your Clinical Distribution More Efficient in Supply Chain Management Blogs by SAP

- sap foreign trade mode of transport change in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |