- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- PM/CS: Configurable Task List - Standard Process

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

peter_atkin

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

12-26-2021

2:03 PM

1. Introduction

Objective: to create a Configurable General Task List and Configured Equipment that will work in planned and corrective maintenance orders.

The basic data creation process:

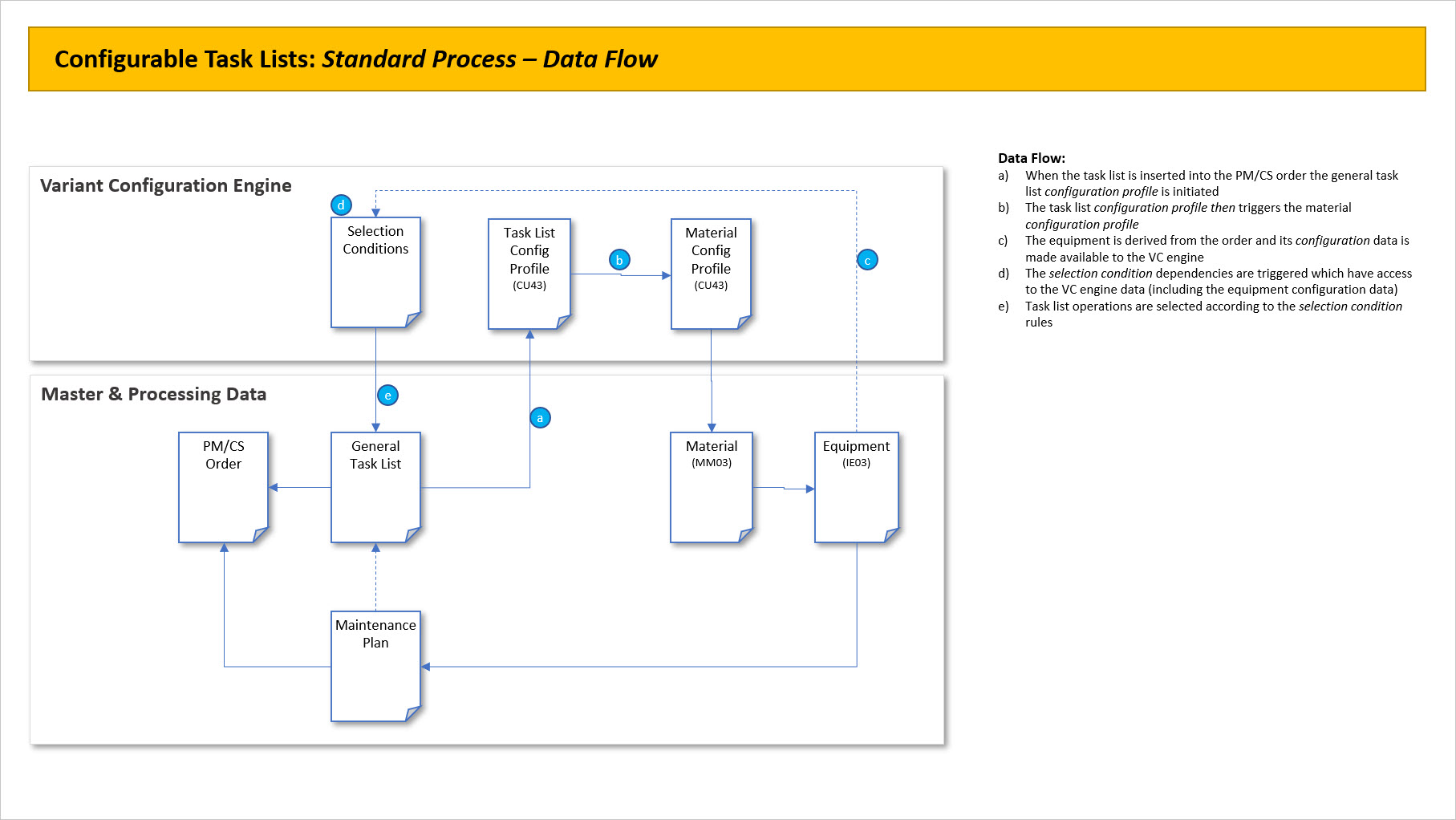

The basic data flow:

In this example we will create a task list with selectable operations based on whether the casing of a pump is cast iron, aluminium, or steel.

2. Configurable Materials

2.1 Define Class/Characteristic Data (CL02/CT04):

Create class type 300 and assign the characteristics as required.

We will use characteristic P_20 later in our task list and equipment.

2.2 Create Configurable Material (MM01):

Create a new material and activate the Basic Data 1, Basic Data 2 and Classification tabs as a minimum.

Assign the class you created in section 2.1 above (you do not need to valuate the characteristics at this point).

2.3 Create Configuration Profile for Material (CU41):

Create a configuration profile via CU41 for the material you created in section 2.2 above and assign the class.

Also ensure that the configuration profile is released.

2.4 Assign Configurable Material to Equipment (IE02):

Go into the equipment master and activate the Configuration tab via menu path: Extras->View Selection, then select the Configuration checkbox.

On the Configuration tab, assign the configurable material you created in section 2.2 above. Then use the Maintain button to populate the characteristic values.

Make sure you populate the housing type as this will be used later in the task list.

Save the equipment.

3. Configurable General Task Lists

3.1 Create Object Dependencies (CU01):

Create new object dependencies (selection conditions) for each of the dependent operations you need to select.

Examples:

• Diesel engine

• Electric engine

The VC code format is <CHARACTERISTIC_NAME> = <CHARACTERISTIC_VALUE>

Example: ENGINE_TYPE = 'DIESEL'

Logical OR, AND, etc. functions can be used.

Example: ENGINE_TYPE = 'DIESEL' OR ENGINE_TYPE = 'ELECTRIC'

In our case we are interested in characteristic P_20 and value "A".

Create two more object dependencies for values "S" and "G".

Ensure the dependencies are released.

3.2 Create General Task List (IA05):

Create a general task list and assign the relevant operations.

Then use menu path: Extras->Object Dependencies->Assignments to assign the object dependencies you created in section 3.1 above.

Note: do not assign dependencies to those operation which you want to always transfer to the order.

3.3 Create Configuration Profile for General Task List (CU41):

Create a configuration profile for the general task list you created in section 3.2 above and assign the class defined in section 2.1 above.

Ensure the profile is released.

4. BOM Items

You cannot assign object dependencies to the components within the task list operations. This can only be done in a BOM external to the task list. And since we are using a general task list, it makes sense to use a Material BOM.

The following section describes how to include selectable BOM items for the task list operations or sub-operations.

4.1 Create a Configurable Material (MM01):

We need to crate a material for our material BOM. In this case I am using material type IBAU, but you can use other material types if required.

You must ensure that the Material is configurable checkbox is set on the Basic Data 2 tab.

4.2 Create a BOM with Dependencies(CS01):

Now we can create our material BOM for the relevant plant. The components are added to the BOM as required, and then we us the following menu path to assign our object dependencies: Extras → Object Dependencies → Assignments

In this example we will create two object dependencies. The first is a selection condition dependency which will determine if the BOM item should be selected, the 2nd is a procedure dependency which changes the item quantity:

4.3 BOM Assignment to the Task List (IA06):

The material BOM is now assigned to the task list header using the assembly field.

Assignment of the material BOM to the header makes all the BOM items available for selection on the operations.

In the example below we can see that operation 0060 has three components assigned. We can also see that component 100-200 has two object dependencies that we created and assigned above.

5. Testing

5.1 Testing with Manually Assigned Task Lists (IW31/2):

Create or change an existing order and ensure that the configured equipment is entered in the order header.

Select the configurable general task list via menu path: Extras->Task List Selection->General Task List:

A classification screen should now be displayed and the characteristic values copied from the equipment. You can change these if required. Notice that the values have been derived from the equipment master:

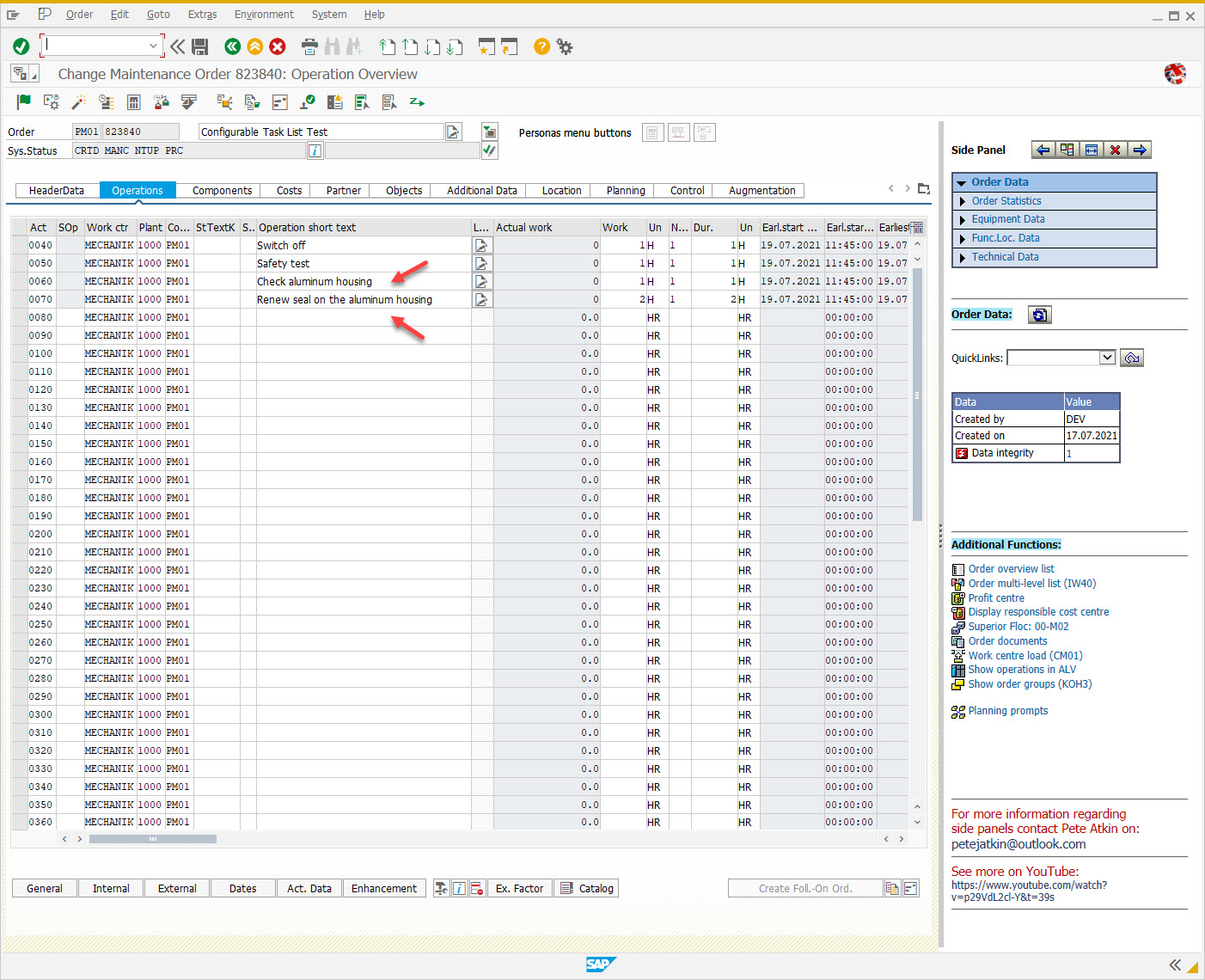

Green-arrow back out of this screen and the order should now be updated with the relevant operations i.e. those operations that satisfy the object dependency parameters, or those operations with no object dependency assignments.

5.2 Testing with Maintenance Plans (IP10):

Create a maintenance plan for the configurable equipment you created in section 2.4 above.

Schedule the plan via IP10 and release one of the calls.

The order should now be created with the relevant operations i.e. those operations that satisfy the object dependency parameters, or those operations with no object dependency assignments. Notice that the classification popup does not appear in this case.

5. Appendix

SAP Help:

In this series:

- PM/CS: Configurable Task List - Standard Flow

- PM/CS: Configurable Task List - without Equipment Configuration

- PM/CS: Configurable Task List - Seasonal Operations

- PM/CS: Configurable Task List - Object Dependencies

Here are some other useful blogs:

- PM/CS: Side Panels in GUI for Windows

- FAQ: SAP Plant Maintenance Transactions

- FAQ: Plant Maintenance Cut-Over Activities/Tasks

- FAQ: PM/CS Reports

- FAQ: List Edit Reports

- FAQ: PM/CS Cost Reports

- PM/CS: Task List Header & Operation Report via SQVI

- SAP Query using Standard Program Reports (SQ01 and SQ02)

- FAQ: Master Data Load Sequence

- FAQ: Alternative Printing Options

- FAQ: Resource Related Billing (DP90)

- FAQ: PM/CS Upload/Download Options

- FAQ: Maintenance Order Scheduling

- FAQ: PM/CS Tables

- FAQ: Finding Tables in SAP

- FAQ: PM/CS Enhancement Options

- FAQ: PM/CS User-Exits, BADIs, BTEs & BOR Objects

- FAQ: PM/CS Authorisation Objects

- Changing Your SAP GUI Colours

- PM/CS: Search Helps

- SAP Managed Tags:

- PLM Enterprise Asset Management (EAM)/Plant Maintenance (PM)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Intercompany Billing - Func.Area and Porfit center determination in Enterprise Resource Planning Q&A

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Introducing the market standard of electronic invoicing for the United States in Enterprise Resource Planning Blogs by SAP

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- Output Type SPED trigger Inbound Delivery after PGI for Inter-Company STO's Outbound delivery in Enterprise Resource Planning Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |