- SAP Community

- Products and Technology

- Technology

- Technology Blogs by SAP

- Predictability in manufacturing leads to profitabi...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Aerospace and Defense (A&D) is a rapidly changing industry. And this is great if you are the one leading the change. A&D companies are able to succeed by becoming data driven, providing instant insights and services to manage the volume, variety and velocity of data. Even as A&D industry is one of the pioneers in adopting digitalization, they have to extend digital technologies far beyond engineering in order to increase throughput and quality at lower costs. A further step towards digital aviation as a whole will be the establishment of predictive analytics.

Extension of analytics capabilities.

Extension of analytics capabilities.

The key is unlocking data to move decision making from sense & respond to predict & act.

The most common use case of predictive analytics is predictive maintenance of air- and spacecraft in ongoing operations.

So far, so good. But is there anything else to get out of it? Sure!

Now it is time to exert predictive analytics in the value chain much earlier, namely in manufacturing processes.

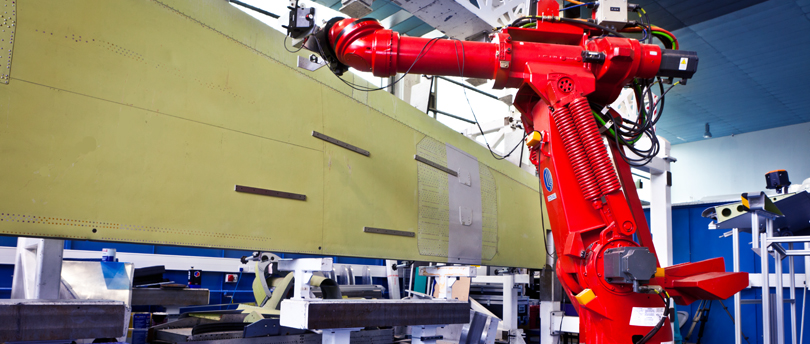

The applicability of predictive analytics raises manufacturing to the next level, which is, for instance, required by the continuous increase of composite share. Such as the latest Airbus A350 XWB consists of 53% hardly fabricable composite material, including wings as the largest single aviation parts ever made from carbon fibre.

With the help of the latest available technologies, for example, accurate predictive analytics, hyperconnectivity and super computing power, all production machines can automatically act on analysis of constant streams of data. Thus, the interconnected machines are able to speed up root cause analysis, looking for links between quality and variation of the production process, hence self-correct or call for maintenance, resulting in an effective quality security system.

Vision: Internet of Things + machine learning + condition monitoring = forecast of any machine failure

Rapid identification or prediction of production quality issues based on large volumes of sensor data, provides a significant business case for A&D manufacturer. In order to avoid rework by timely corrective maintenance of the production machines, two major use cases are currently seen:

- Analyzing the deviation of specific equipment using measurement data of final products along time. Due to an historical evaluation on a timeline and correlation between different measurements, deviations of the equipment and the products are even predictable. This ensures greater quality assurance with the help of essential inspections and maintenance for the equipment before produced parts will be rejects. Definitely at the right time, since Run-to-failure is not a strategy embraced by the aerospace manufacturing industry.

- The next configuration level is monitoring and visualizing certain parameters or variables during manufacturing processes of long duration in real-time, like milling of large parts. If it is foreseeable, that a component will be out of tolerance and consequently be a scrap part, the machine will stop immediately. A maintenance scenario for the production machine will follow, with the objective to save time and money. Airbus, for example, plans to produce 60 A320 a month starting in mid of 2019. To achieve this, defective production on the shop floor is unacceptable.

Another very attractive case of application for predictive analytics in manufacturing is the No-Fault-Found scenario, especially in the A&D industry. The No-Fault-Found scenario describes an issue, where an assembled part diverges from the standard norm and performance, even though all single components passed their quality tests. Predictive analytics provides the opportunity to analyze complex combinations of parameters, which lead to the failure.

Always keep in mind: Predictability = Profitability

To simplify and accelerate Manufacturing Execution Systems, SAP offers predictive analytics on in-memory data base SAP HANA to reduce time spend on fault finding, avoid rework and consequently lower costs, increase throughput and improve profitability. Providing new insights by intuitive user interface, the combination of analytics and 3D visualization will act as pioneering technology.

This is just one example of digital transformation, turning aircraft manufacturing into a smarter one.

So trust aircraft wings when boarding next plane! Following complex composite wing structures are going to be manufactured in excellent quality.

Other examples of digital transformation in aerospace:

Everything in manufacturing needs to be digital

Fasten your seatbelts! Next generation of finance transformation is on the way

You might also like:

5 Reasons why Chinese aircraft manufacturer will become a global contender

- SAP Managed Tags:

- Digital Technologies,

- Aerospace and Defense,

- SAP Predictive Analytics,

- SAP HANA,

- MAN (Manufacturing)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

ABAP CDS Views - CDC (Change Data Capture)

2 -

AI

1 -

Analyze Workload Data

1 -

BTP

1 -

Business and IT Integration

2 -

Business application stu

1 -

Business Technology Platform

1 -

Business Trends

1,658 -

Business Trends

91 -

CAP

1 -

cf

1 -

Cloud Foundry

1 -

Confluent

1 -

Customer COE Basics and Fundamentals

1 -

Customer COE Latest and Greatest

3 -

Customer Data Browser app

1 -

Data Analysis Tool

1 -

data migration

1 -

data transfer

1 -

Datasphere

2 -

Event Information

1,400 -

Event Information

66 -

Expert

1 -

Expert Insights

177 -

Expert Insights

296 -

General

1 -

Google cloud

1 -

Google Next'24

1 -

Kafka

1 -

Life at SAP

780 -

Life at SAP

13 -

Migrate your Data App

1 -

MTA

1 -

Network Performance Analysis

1 -

NodeJS

1 -

PDF

1 -

POC

1 -

Product Updates

4,577 -

Product Updates

342 -

Replication Flow

1 -

RisewithSAP

1 -

SAP BTP

1 -

SAP BTP Cloud Foundry

1 -

SAP Cloud ALM

1 -

SAP Cloud Application Programming Model

1 -

SAP Datasphere

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Migration Cockpit

1 -

Technology Updates

6,873 -

Technology Updates

420 -

Workload Fluctuations

1

- Partner-2-partner collaboration in the construction industry in Technology Blogs by SAP

- Streamline Your Cash Flow with SAP Cash Application: Your Guide to Faster Payments & Efficiency in Technology Blogs by SAP

- Learn SAP Signavio for Free?! in Technology Blogs by SAP

- SAP Best Practices Baseline Package - Function List - Transactions in Technology Blogs by Members

- Brazil’s SME Partners dive into SAP Analytics Cloud in a hybrid Hack2Build experience in Technology Blogs by SAP

| User | Count |

|---|---|

| 36 | |

| 25 | |

| 17 | |

| 13 | |

| 8 | |

| 7 | |

| 7 | |

| 6 | |

| 6 | |

| 6 |