- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Rescheduling of production proposals based on comp...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Employee

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-04-2020

3:41 PM

The objective of this blog post is to explain how you can use the pegged supply UI enhancements done with 2005 to come to a feasible production plan considering the component availability.

Basis for the feasibility analysis is the planned material flow, that is calculated during material planning run execution. The planned material flow is a link between a demand element like forecast, sales order, or a component (dependent) demand, and a supply element like inventory, purchase orders, or production proposal output. This link is often also referred to as ‘pegging’. It explains, what quantity of a certain supply element was used by the planning run to fulfill a certain demand element.

Thus, the material flow can also be used as an explanation of the results of a material planning run.

In the example above a typical pegging network is illustrated.

There are several UIs in the work centers Supply Planning and Supply Control like the ‘Material Flow’, ‘Pegged Supply’, or ‘Top-level Pegged Demand’, that are based on this information.

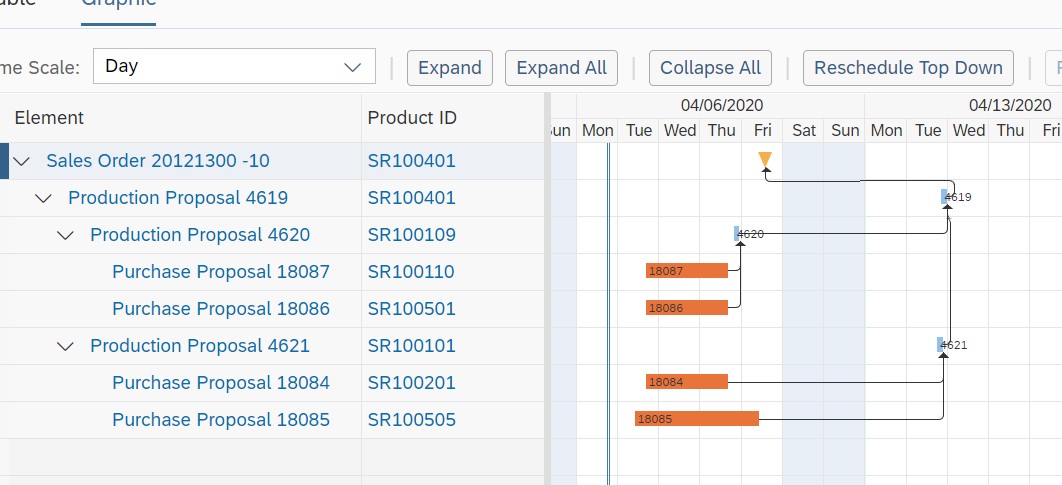

Imagine the following planning situation: A sales order to be shipped on Friday requires a two-level production, and the corresponding components of the lower production level need to be purchased. As you can see one component (purchase proposal 18085) can only be delivered late.

Of course, a planner does not want to analyze the material flow for each sales order individually. Instead, he might first need to check which of the production proposals has a late component.

He can do this by selecting a set of production proposals in the Supply Control work center, view ‘Process Production Proposals’ and navigate to the ‘Pegged Supply’ UI:

You can see that a new column ‘Component Delay’ was added in the upper table with release 2005 to highlight, that one of the components of production proposal 4621 is not available on time. The corresponding pegged supply elements are listed in the lower table. Again, the ‘Component Delay’ column allows you to identify the delayed document.

A new navigation ‘Open Material Flow’ was added in the lower table to directly access the complete material flow UI for the delayed supply element:

To solve the planning issue a bottom-up scheduling can now be performed. It is important to understand that the bottom-up scheduling can only be done from the reference document upwards, while the reference document is the one, for which the material flow UI was launched.

After bottom-up scheduling, the situation looks like this:

The corresponding production proposals are moved into the future, so that they will only start once the components are available.In addition it is easy to understand the impact of the late component on the pegged sales order.

Please also have a look at this video.

Basis for the feasibility analysis is the planned material flow, that is calculated during material planning run execution. The planned material flow is a link between a demand element like forecast, sales order, or a component (dependent) demand, and a supply element like inventory, purchase orders, or production proposal output. This link is often also referred to as ‘pegging’. It explains, what quantity of a certain supply element was used by the planning run to fulfill a certain demand element.

Thus, the material flow can also be used as an explanation of the results of a material planning run.

In the example above a typical pegging network is illustrated.

There are several UIs in the work centers Supply Planning and Supply Control like the ‘Material Flow’, ‘Pegged Supply’, or ‘Top-level Pegged Demand’, that are based on this information.

Imagine the following planning situation: A sales order to be shipped on Friday requires a two-level production, and the corresponding components of the lower production level need to be purchased. As you can see one component (purchase proposal 18085) can only be delivered late.

Of course, a planner does not want to analyze the material flow for each sales order individually. Instead, he might first need to check which of the production proposals has a late component.

He can do this by selecting a set of production proposals in the Supply Control work center, view ‘Process Production Proposals’ and navigate to the ‘Pegged Supply’ UI:

You can see that a new column ‘Component Delay’ was added in the upper table with release 2005 to highlight, that one of the components of production proposal 4621 is not available on time. The corresponding pegged supply elements are listed in the lower table. Again, the ‘Component Delay’ column allows you to identify the delayed document.

A new navigation ‘Open Material Flow’ was added in the lower table to directly access the complete material flow UI for the delayed supply element:

To solve the planning issue a bottom-up scheduling can now be performed. It is important to understand that the bottom-up scheduling can only be done from the reference document upwards, while the reference document is the one, for which the material flow UI was launched.

After bottom-up scheduling, the situation looks like this:

The corresponding production proposals are moved into the future, so that they will only start once the components are available.In addition it is easy to understand the impact of the late component on the pegged sales order.

Please also have a look at this video.

- SAP Managed Tags:

- SAP Business ByDesign

Labels:

6 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

152 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

206 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

87

Related Content

- SAP S/4HANA Cloud Public Edition 2402.2: Final What's New & Product Assistance available in Enterprise Resource Planning Blogs by SAP

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 6 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |