- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Concept of Alternative Sequence of Operation and h...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Alternative sequence

Alternative sequences contain operations that replace the operations in the standard sequence. They are used for example if- the production process in the order is changed for certain lot sizes or

- alternative capacities are available that can be used as alternatives in the case of capacity bottlenecks

Now in the following screen shot it describes the standard sequence of Operation and the alternative sequence of operation.

Alternative Sequence of Operation is valid for the lot size 500 to 99999999. the branch operation is 0030 and the return operation is 0040.

Standard Sequence of Operation

Alternative Sequence of operation

Graphical Overview of Operation

So the above screen shot shows that the product can be produced either using the standard sequence of operation 0010-->0020--->0030--->0040--->0050 or else

using 0010--->0020--->0035(single operation in the alternative seq)--->0050(Thread Cutting).

Production Order Creation

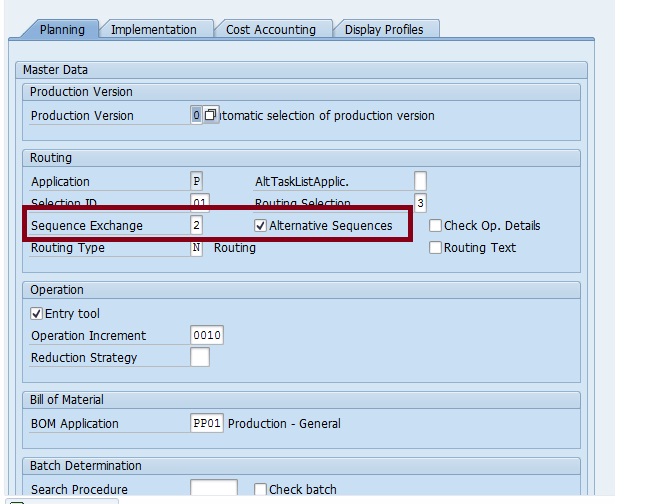

Ensure in the Order type dependent Parameters the necessary configuration setting is included for the alternative sequence and in the below screen shot

sequence exchange value is set as 1-Always Automatic selection by lot size of alternative sequence.

Now in the below screen shot the order quantity is entered as 600,

In the operation overview of the production order the system automatically copies the sequence of operation as 0010-->0020--->0035--->0050.

Similarly for an order quantity of 100,the system copies the standard sequence of operation, that's 0010--->0020--->0030--->0040-->0050.

Scenario 2:

In case if in the alternative sequence no lot size is maintained means(default from 1 to 99999999) then in the order type dependent parameters maintain the value

for sequence exchange as 2 - Manual selection,then during production order creation, the system issues the following popup to choose the sequence of

operation.

If No is selected means, then the system copies the standard sequence of operation and if Yes is selected then the alternative sequence of operation gets

copied into the production order.

Thanks for reading this blog.

Kindly share your comments.

Regards

Mangalraj.S

- SAP Managed Tags:

- MAN Production Planning (PP)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Inspection type 03 result recording accept reject impact on next operation confirmation and GR. in Enterprise Resource Planning Q&A

- FAQ: S/4HANA Cloud, public edition - Sales in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA alternative BOM in CU50 in Enterprise Resource Planning Q&A

- Production order : double confirmation B10 for the same personal number in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |