- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- Operational Risk Management in SAP S/4HANA Cloud P...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction

Nearly all countries in the world have implemented regulations that require the employers to protect their employees from work-related harm. This aspect of a company's process landscape is usually called operational or occupational risk management, sometimes the term industrial hygiene is used in that context, often it's simply workplace safety.

The solution Environment, Health, and Safety (EHS) as part of SAP S/4HANA delivers various processes in the area of workplace safety. The most prominent and most central process hereby addresses the topic of operational risk assessment, where potential hazards for employees are identified, recorded, assessed and mitigated.

SAP S/4HANA, Public Edition 2308 delivers a new app called Manage Risk Assessments which handles all the above aspects of an operational risk assessment. This blog post provides a process overview and shows a demo video about the described process.

Process Overview

The video below visualizes the following process:

- An employee observes a safety relevant situation and records it in the system.

This initial step is not part of the video. - This near miss is evaluated and processed by an incident manager.

- At the end of the evaluation, the incident manager creates a task to trigger a re-assessment of the risk situation at the relevant workplace.

- The responsible person for the workplace (usually a plant or production manager) receives the task in their Inbox.

This step is not shown in the video. - The responsible person opens the relevant risk assessment record and adds the new hazard/risk Slips and Trips to it.

- The new risk is assessed by defining a risk level.

- The new risk is mitigated by assigning a control.

- The new risk's assessment is finalized by setting the new control to implemented.

Demo Video

Process Details

Step 1: Creating a Near Miss

A near miss is a work-related situation where an incident or accident just didn't happen. In other words: "Whew! That was close!"

It is utterly important to not only track and look at actual incidents, but to also keep track of near misses (and similar safety relevant situations), because - according to statistics - after a number of these "harmless" situations, an actual harmful incident will happen at that workplace.

Step 2: Incident Evaluation

The video does not show the full incident evaluation but only the result of it: The incident happened due to a material defect.

Step 3+4: Creating a Task for Risk Assessment

The EHS solution shares the common feature of Task Management, which means that tasks defined in one functional area of EHS can show up and have effects on other EHS areas.

In our example, the incident manager defines a task inside the incident processing which is then received by the responsible risk manager (usually this is the production or plant manager) of the relevant workplace.

Step 5: Adding a new Hazard

When looking at the existing risk assessment, the risk manager realizes that the hazard Slips and Trips has not been considered yet. So a new risk with the appropriate hazard is added.

Step 6: Assessing the Risk

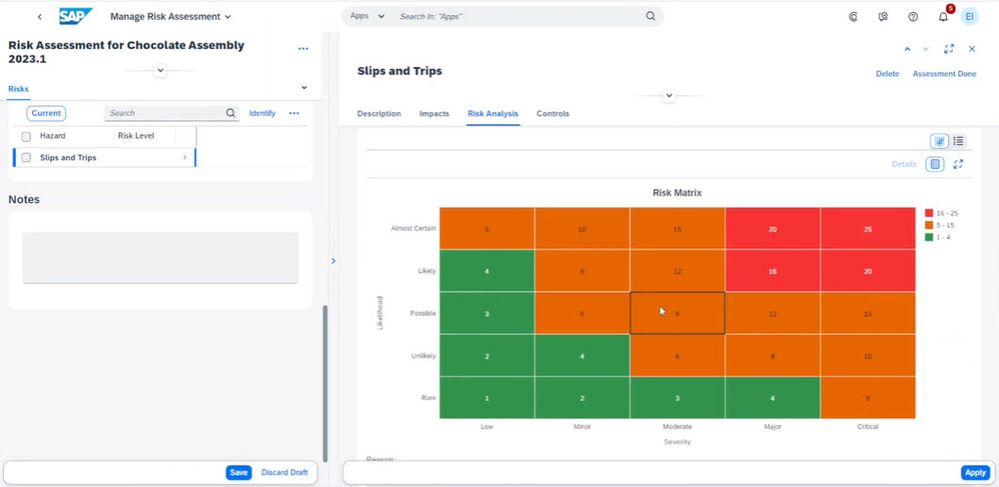

Assessing a hazard or risk usually means to define how serious this hazard is from a safety point of view for the working environment and the performed tasks. Usually this risk level is defined along a so called risk matrix, where the likelihood and the severity of a hazard together define the resulting risk level.

In the video the following assessment is performed:

- The likelihood (= y-axis of the risk matrix) was assessed as "Possible", which means that there is a medium probability that this problem occurs.

- The severity (= x-axis of the risk matrix) was assessed as "Moderate" because the effect from slipping usually is not that grave.

- These two assessments result in a risk level of 9, which lies somewhere in the middle of the possible range of 1 to 25. Therefore it gets a Risk Level of Medium

Step 7: Assigning a Control

Risks of risk level Medium and High usually need mitigation, which means that certain measures (called controls) must be defined to lower the risk level. These measures usually are from one (sometimes multiple) of the following categories and have to be chosen in the shown order of priorities:

- Engineering measures

Example: Installation of an air vent - Organizational measures

Example: Training - Person-related measures

Example: Personal protective equipment

In our example, the risk manager assigns a rubber mat as control to lower the risk of slipping.

Step 8: Implementing the Control

Assigning a control only means that the risk manager plans to install that control. But this does not mean that it will be installed right away. Sometimes this takes quite some time, and during that time the risk still is on its initial high level.

Only after successful installation of the control, the risk level can be adjusted (i.e. lowered; not shown in the video) and the risk can be closed afterwards by setting it to Assessment Done.

Summary

This blog described the usual steps of an operational risk assessment process, enhancing this with a demo video showing the described process in the actual software. This gives a good idea of the process as well as of the new S/4HANA app Manage Risk Assessments.

Further information about the mentioned app can be found on the SAP Help Portal.

- SAP Managed Tags:

- SAP Environment, Health, and Safety Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Quick Start guide for PLM system integration 3.0 Implementation in Product Lifecycle Management Blogs by SAP

- Transition from SAP Solution Manager to SAP Cloud ALM with help from SAP Enterprise Support in Product Lifecycle Management Q&A

- Striking the Perfect Balance in Product Lifecycle Management Blogs by SAP

- A Comprehensive Breakdown: The Pros and Cons of Product Lifecycle Management in Product Lifecycle Management Blogs by SAP

- MII configuration and content transport management in Product Lifecycle Management Blogs by SAP

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |