- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- What is Wrong with the Pallet Storage Strategy in ...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

DominikTylczyn

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-29-2023

1:45 PM

Introduction

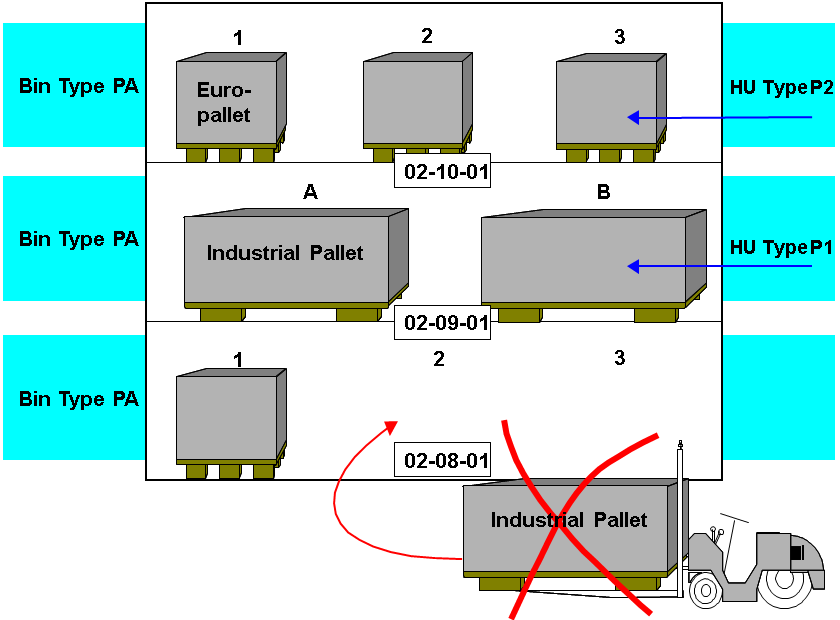

The pallet storage strategy P is available both in EWM and LE-WM. Its key feature is that depending on a handling unit (or storage unit in case of LE-WM) type, a storage bin is dynamically divided into sub-bins (or sections):

Pallet Storage Strategy (source: SAP Help)

The number of bin sections depends on the type of a pallet being placed, for instance if a bin accommodates 3 euro pallets and 2 industrial pallets, the bin is divided into 3 sections upon the placement of an euro pallet into the empty bin and into 2 sections upon the placement of an industrial pallet.

The beauty of this approach is that bins are divided dynamically during placement. It is not needed to create separate bins for euro pallets and industrial ones.

SAP Help documentation:

SAP Help documentation of the strategy for EWM and LE-WM is very similar if not identical. Therefore the strategies must work the same in both systems.

Notice, that the documentation always uses a sequence of bin section numbers from left to right. In real life however, very often the first pallet is placed in the leftmost section, the second one in the rightmost section and the third one in the middle location. That reduces a risk of damages during storage.

Prompted by a question from marcuss I have checked how the strategy works in EWM and LE-WM.

I have run the same test case in both systems, i.e. placing of 3 handling / storage units with the same bin sectioning E D C B A.

I would expect the following placement results:

- the first handling/storage unit -> section E,

- the second handling/storage unit -> section D,

- the third handling/storage unit -> section C.

Additionally, the results in EWM and LE-WM would have to be the same as there are no differences in the strategy P behaviour in both systems.

Pallet Storage Strategy in SAP EWM

Bin sections (sub bins) in EWM

I have started with an inbound delivery with three handling units:

The Initial Inbound Delivery

Then, I have created the stock placement warehouse tasks for the handling units:

Placement with Strategy P in EWM

Notice, that the first task has been placed as expected into sub bin E. However the other two task have been placed into sections A, B, not into D and C as expected and as defined in the bin sections configuration.

Surprised by the odd result, I have rerun exactly the same test in LE-WM.

Pallet Storage Strategy in SAP LE-WM

Bin Sections in LE-WM

Placement with Strategy P in LE-WM

Notice, that LE-WM has placed the storage units exactly as expected and as defined in the bin sections configuration.

Technical Details

I just could not leave it like that and needed to get to the bottom of it. I have debugged the placement strategy in EWM, which is defined in the /SCWM/PUT_BIN_DET function group.

In my opinion the root cause of the issue is the empty bin buffer sorting logic implemented in the BIN_DETERMINATION_2 form routine - lines 140-158. The logic does not refer to the bin sectioning configuration whatsoever:

Empty Bins Buffer Sorting Logic

During the first warehouse task creation, the state of the buffer is as follows:

Empty Bins Buffer During the First Task Creation

Notice that the sub bin 0070-01-01/E is the first one in the buffer. Hence the first task goes to this sub bin, which is the expected result.

However, just before subsequent tasks are created the buffer is sorted and its state is as follows:

Empty Bins Buffer During Subsequent Tasks Creation

The way the buffer is sorted explains why the second and the third handling units are placed into bin sections A and B, instead of D and C.

It looks like the pallet storage strategy P does not respect bin sections configuration when sub bins are already created and sorts them as regular empty bins.

Conclusion

The tests have been conducted on S/4HANA 2022 FP01 system with embedded EWM. That is a quite recent release. I have also reviewed support notes, but to no avail.

Honestly, I am stunned. The pallet storage strategy P is one of the basic features of EWM. It must be commonly used by numerous customers. Have anyone not noticed that problem yet? Or am I missing something?

I would appreciate your comments and experience sharing with the pallet storage strategy P. Correct me if my conclusions are wrong.

Maybe the EWM product owner from SAP sheds some light on this?

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- EWM - Goods Movement,

- LE Warehouse Management

19 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- Practical Insights into New Features of SAP EWM in S/4HANA 2023 in Supply Chain Management Blogs by Members

- Outbound with LOSC and POSC in Supply Chain Management Blogs by Members

- putaway by HU typens without a storage location indicator in Supply Chain Management Q&A

- SAP EWM Bin Capacity check based on Check Acc. to Key Figure Packaging Material in Supply Chain Management Blogs by Members

- /SCWM/REPL fails when creating HU WT but /SCWM/ADHU is ok in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |