- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Inventory "adjustments" to dates in the past

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ferspk1

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-27-2023

6:57 PM

In your SAP Business ByDesign system, you may need to make adjustments in your inventory.

You will use the "Physical Inventory count" documents to manage your inventory counts:

And you can use "new inventory adjustment" to make adjustments to some records of your inventory (you can select them in the search results list):

Perhaps, for some reason, you may need to make an adjustment to a date in the past.

For exemple, after your go-live, you discover that there was some errors in your loaded inventory. How can you adjust them?

You might see the field "Key Date" and think you can use it to adjust your inventory in date in the pas. You will be wrong. Why? How do these screens work?

The "new inventory adjustment" calculates the difference between the quantiy you set in the screen and the quantiy in your stock TODAY (at the moment you are in the transaction). The system doesn't use the theorical quantity of your stock on the "Key Date" reported on the screen. The "Key Date" is used only as the accounting date for your inventory adjustments.

But, then, how can you handle this type of situation when you need to make one or more adjustments in a past date?

Imagine this example, where your initial loaded stock was "20 bottles" on 31.12.2022

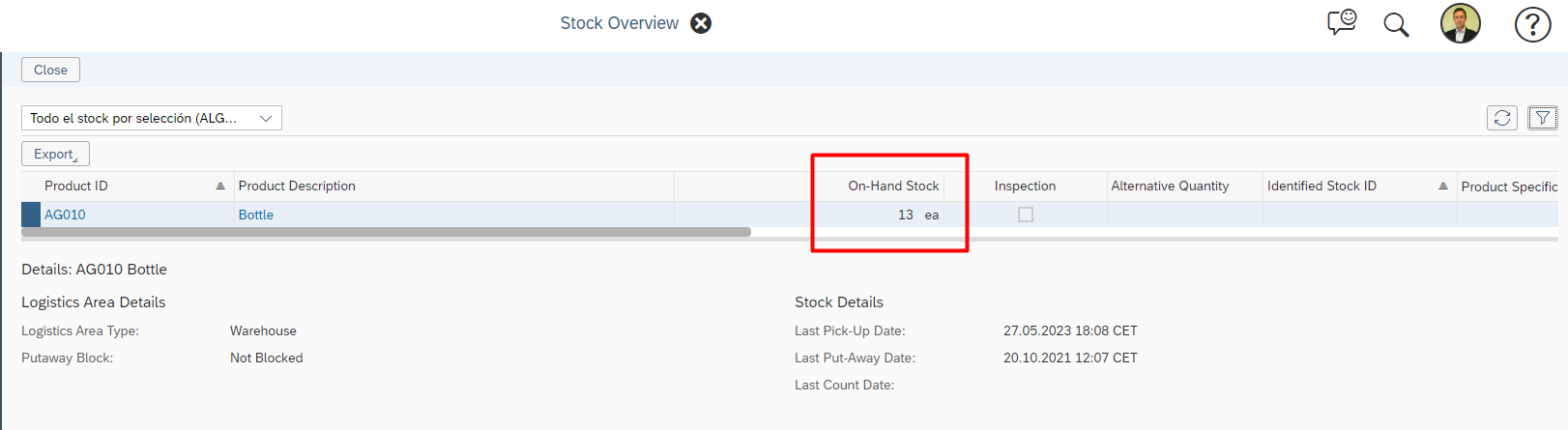

But your stock today (27.05.2023) is "13 bottles"

If you start a new inventory adjustment for this product and try to set "21 bottles" as the quantity in the key date "31.12.2022"

you could expect the system to calculate a different of "1 more bottle" compared to the inventory balance on 31.12.2022

However, the system calculates a difference of "8 bottles", because it takes today's quantity ("13 bottles") compared to the quantity that you fill on the screen ("21 bottles")

If you continue, your inventory balance at 31.12.2022 will show 28 bottles (20 + 8), because the key date is used as the accounting date:

The only way to adjust the inventory to "21 bottles" as of 31.12.2022 is to use a "Return from a Cost Center" with "1 bottle"

You must to establihs a cost center for the accounting of this operation.

In this way, you'll get the inventory balance you need as of 31.12.2022:

However, the main problem with this procedure is that you have to calculate your differences by product and fill the screen one by one, manually.

Automation of the adjustments

If you have a long list of adjustments, maybe you can think in some kind of automation

Here I share some tips that can help you achieve it:

- Get inventoy balance quantity using ODATA for Analytics

https://<your_system_url>/sap/byd/odata/scm_physicalinventory_analytics.svc/RPSCMINBU03_Q0001QueryRe... eq '<your-material-id>' and CLOG_AREA_UUID eq '<your-location + "/" + your-logisticarea-id>' and PARA_ENTRY_PERIOD eq datetime'2022-12-31T00:00:00'&$select=KCENDING_QUANTITY&$format=json

In our example:

https://myXXXXXX.sapbydesign.com/sap/byd/odata/scm_physicalinventory_analytics.svc/RPSCMINBU03_Q0001... eq 'AG010' and CLOG_AREA_UUID eq 'ESO101/ESO101-30' and PARA_ENTRY_PERIOD eq datetime'2022-12-31T00:00:00'&$select=KCENDING_QUANTITY&$format=json

You get something like this:

the fields "KCENDING_QUANTITY" and "UCENDING_QUANTITY" tell us that we have 20 EA of this product, in this area, as of 31.12.2022

If you work with identified stocks, you will need to add an expression like this to the filter:

" and CISTOCK_UUID eq '<your-product>+"/"+ <your-identified-stock>' "

- Calculate the differences

Once you get the quantities from the inventory balance on your adjustment date, you must calculate the differences with your "actual stock" on that date. The result can be positive or negative.

- Use the inbound service to create the consumption/return

You can use the Operation Do Goods Consumption for Cost Center of the Inbound Service InventoryProcessingGoodsAndActivityConfirmationGoodsConfirmationIn to create a consumption (if your real stock is less than your original stock) or a return (if your real stock is greater than your original stock), on your key date.

Remember that you need to set the cost center for this operations

Here you can see a sample tool for adjustments automation using an Excel spreedshet

With these tips, I think you can build your own tool for automatization

Feel free to contact me if you need some kind of support

Fernando Alonso

- SAP Managed Tags:

- SAP Business ByDesign

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Cannot create a Single-date Order ECO using a custom OData service in Enterprise Resource Planning Q&A

- Add Header Text in Basic Date of Supplier Invoice in Enterprise Resource Planning Q&A

- A direct consumption PO with Account Assignment category K in Enterprise Resource Planning Q&A

- SAP S4HANA Cloud Public Edition Logistics FAQ in Enterprise Resource Planning Blogs by SAP

- Stock Ageing Report just gone live of SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |