- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- Characteristics-Based Dispatching in SAP Digital M...

Product Lifecycle Management Blogs by SAP

Dive into product lifecycle management news, learn about digitalizing PLM for the digital supply chain, and stay informed with product updates from SAP.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-30-2023

1:02 PM

Efficient resource allocation and effective production scheduling are crucial, and SAP Digital Manufacturing (SAP DM) Resource Orchestration (REO) offers a powerful solution to manage and optimize last mile shop floor scheduling of operations.

In this blog post, we'll take a look into the exciting new feature of characteristics-based dispatching in SAP DM REO and discover how it can significantly enhance production planners' control over operation dispatching.

Demo

https://sapvideoa35699dc5.hana.ondemand.com/?entry_id=1_1b1och7o

Benefits of Characteristics-Based Dispatching

Characteristics-based dispatching in SAP DM Resource Orchestration offers a lot of benefits that can significantly improve production efficiency and streamline the manufacturing process.

By enabling endless scheduling options based on specific criteria, this feature enables manufacturing plants to optimize resource allocation and reduce costs.

Some key benefits of Characteristics-Based Dispatching include:

Prerequisites to use Characteristics-Based Dispatching in REO

To enable characteristics-based dispatching in SAP DM REO, some prerequisites are needed.

Now proceed with regular operation dispatching and see that operations are dispatched following the sequence depentent rules selected.

Demo

https://sapvideoa35699dc5.hana.ondemand.com/?entry_id=1_1b1och7o

Conclusion

Characteristics-based dispatching in SAP DM Resource Orchestration brings a new level of control and adaptability to the shop floor, empowering production planners to make better-informed decisions, respond to real-time events, and improve overall manufacturing efficiency.

Experiencing SAP Digital Manufacturing

You can have a glimpse and experience several aspects of SAP Digital Manufacturing via the Interactive Value Journeys below:

Do you like this post? Please let me know in the comments section what you think. Any feedback is highly appreciated.

Or, if you have any questions, please check SAP Community Q&A Area, or comment down below.

Thanks,

Manoel Costa

In this blog post, we'll take a look into the exciting new feature of characteristics-based dispatching in SAP DM REO and discover how it can significantly enhance production planners' control over operation dispatching.

Demo

https://sapvideoa35699dc5.hana.ondemand.com/?entry_id=1_1b1och7o

Benefits of Characteristics-Based Dispatching

Characteristics-based dispatching in SAP DM Resource Orchestration offers a lot of benefits that can significantly improve production efficiency and streamline the manufacturing process.

By enabling endless scheduling options based on specific criteria, this feature enables manufacturing plants to optimize resource allocation and reduce costs.

Some key benefits of Characteristics-Based Dispatching include:

- Reduced setup time: Schedule operations with similar characteristics consecutively, such as grouping blue products together before moving on to red products, setup time can be minimized. This leads to a more efficient use of resources and a reduction in production delays.

- Enhanced production line organization: Prioritize operations based on product size, weight, or other attributes. This enables better organization of the production line, reducing the need for shifting products around during the manufacturing process, and ultimately saving time and resources.

- Improved resource utilization: Allocate resources more effectively based on factors such as order priority, demand situation, and resource availability. This helps to minimize idle time and ensure that resources are utilized to their full potential.

- Increased adaptability: Respond to changing shop floor conditions quickly, such as machinery breakdowns or labor shortages. By adjusting the scheduling of operations based on these events, production can continue to run smoothly with minimal disruptions.

- Customizable scheduling: Tailor scheduling approach based on specific plant needs and objectives. This can lead to more efficient processes and better alignment with overall manufacturing goals.

- Enhanced decision-making: By providing a comprehensive overview of the load assignment of resources, planners can make better-informed decisions regarding the allocation and deallocation of operations. This ultimately leads to a more streamlined and efficient production process.

Prerequisites to use Characteristics-Based Dispatching in REO

To enable characteristics-based dispatching in SAP DM REO, some prerequisites are needed.

- Create Characteristics in CT04, ensuring that the "REO_" prefix is used

- Create a Classification in CL01 of Class Type 300 (Variant Configuration), ensuring that the "REO_" prefix is used and assign all relevant Characteristics on the "Char." tab

- Create a "Configurable Material" in MM01, mark "Material is Configurable" flag in "Basic Data 2" tab and assign the Classification on "Classification" tab

- Create a "Configuration Profile" in CU41

- Define the Configurable Material for your Header Material at "MRP 3" tab at "Plant-specific configuration" section

- Click "Configure variant" and assign values to the "REO_" characteristics, click "Save"

- Click "Configure planning variant", click "Save"

- Note that "Variant" and "Planning variant" flags are marked, save the material

- Sync all Master Data to SAP Digital Manufacturing via DRFOUT t-code, including the Header Material and check on Manage Materials app in SAP Digital Manufacturing that Classification and Characteristics are downloaded

- Go to Manage Custom Data app in SAP Digital Manufacturing and maintain "REO_ " Characteristics in Shop Order category as Custom Data

- Go to Manage Integration Workflows app and update <CustomFieldList> section of Production Order Download (LOIPRO05 V2) workflow as shown below:

<CustomFieldList>

<xsl:for-each select="E1VCCHR">

<CustomField>

<Attribute><xsl:value-of select="ATNAM"/></Attribute>

<Value><xsl:value-of select="ATWRT"/></Value>

</CustomField>

</xsl:for-each>

</CustomFieldList>

- Create a Production Order and after Releasing it, go to Header > Configuration (CTRL+F3) and note that "REO_" characteristics are copied over

- Save the Production Order, check LOIPRO05 IDOC in we02 t-code and note that "REO_" characteristics are part of E1VCCHR segment

- In SAP Digital Manufacturing Integration Message Dashboard app, note that "REO_" characteristics are present as Custom Fields

- In Manage Orders app, note that "REO_" characteristics are present as Custom Data Fields

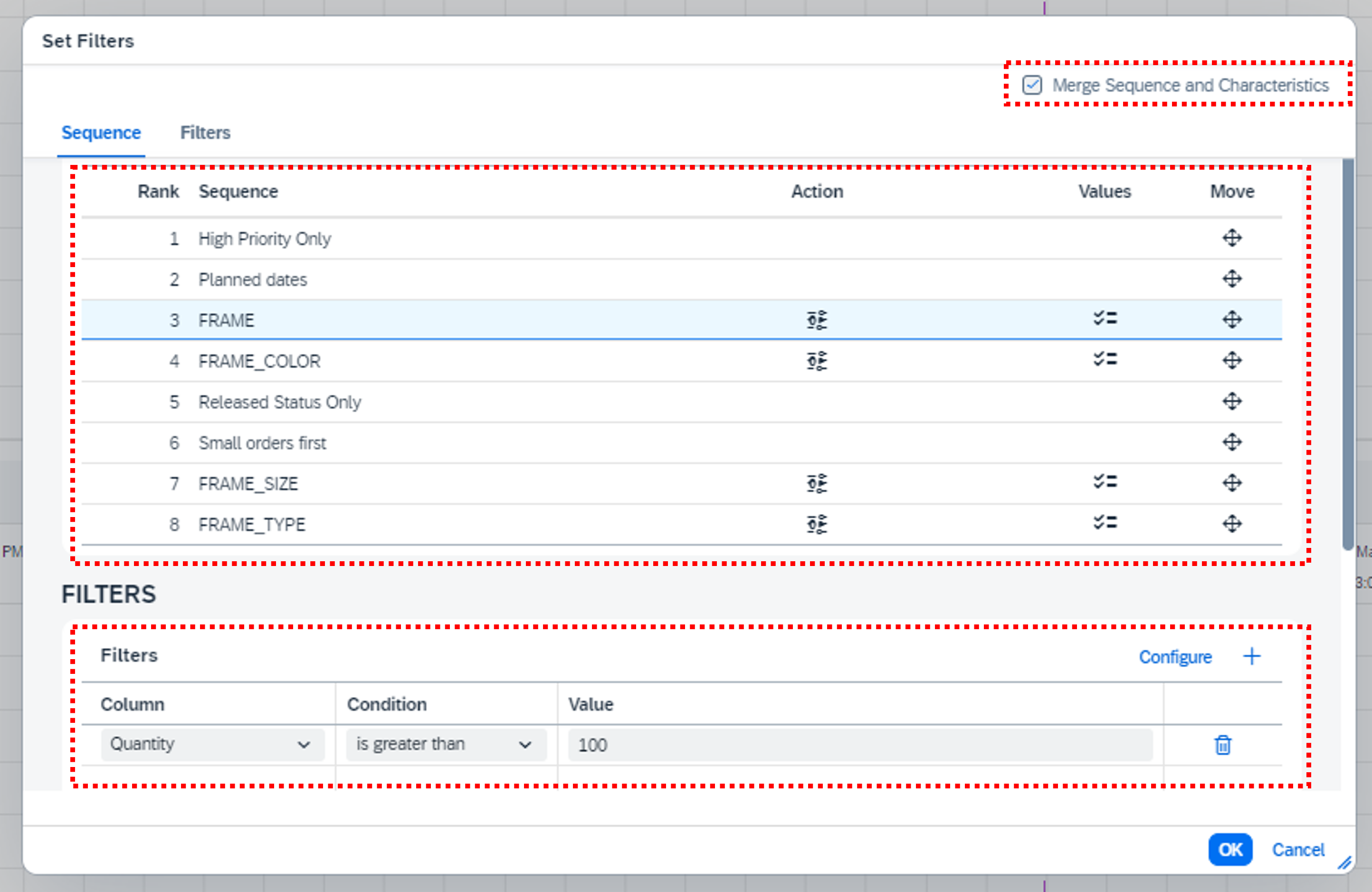

- In Dispatch and Monitoring 2.0 app, click "Filters" on the Worklist

- Under "Sequence Dependent Rules", click "Configure"

- Select all relevant Characteristics and click "OK"

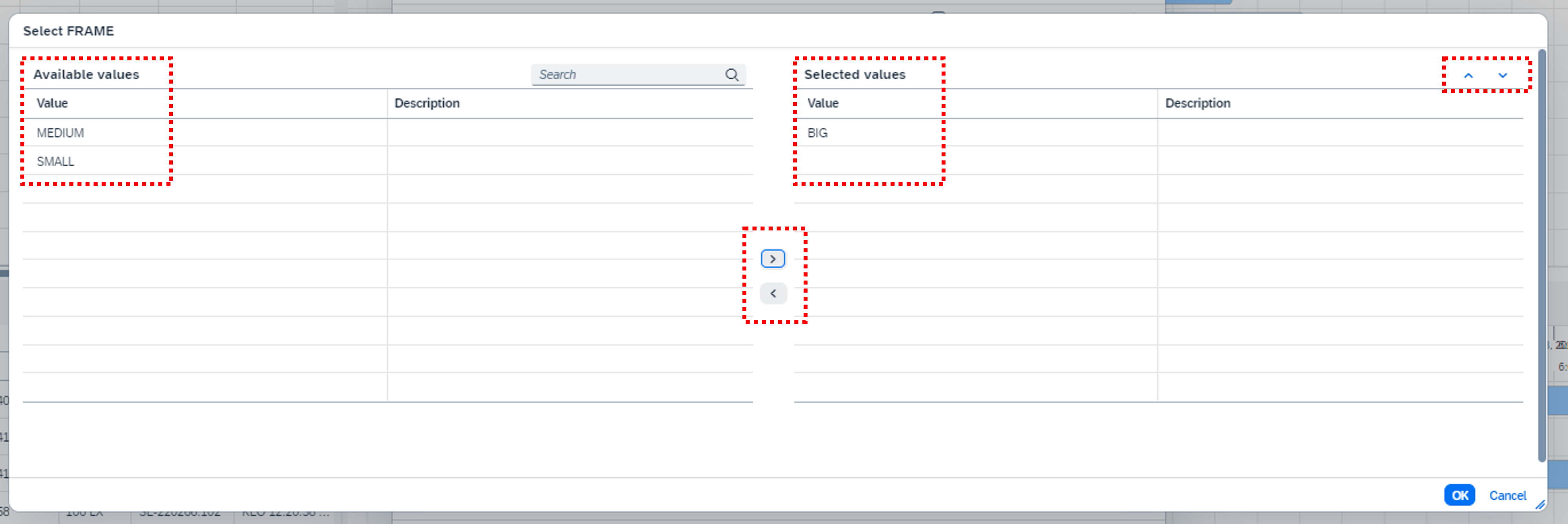

- Use the "Move" column to change the sequence if needed, and click "Configure sequence value" icon on Action column to create Sequence Dependent Rules for each Characteristic

- Define values and sequences for each Characteristic and click "OK"

- Click "Sequence values selected" in "Values" column to see current values and sequence, click "OK"

- Note that Sequence Dependent Rules for Characteristics can be merged with standard dimensions when click the option “Merge Sequence and Characteristics” and with regular Filters as well

Now proceed with regular operation dispatching and see that operations are dispatched following the sequence depentent rules selected.

Demo

https://sapvideoa35699dc5.hana.ondemand.com/?entry_id=1_1b1och7o

Conclusion

Characteristics-based dispatching in SAP DM Resource Orchestration brings a new level of control and adaptability to the shop floor, empowering production planners to make better-informed decisions, respond to real-time events, and improve overall manufacturing efficiency.

Experiencing SAP Digital Manufacturing

You can have a glimpse and experience several aspects of SAP Digital Manufacturing via the Interactive Value Journeys below:

Do you like this post? Please let me know in the comments section what you think. Any feedback is highly appreciated.

Or, if you have any questions, please check SAP Community Q&A Area, or comment down below.

Thanks,

Manoel Costa

- SAP Managed Tags:

- SAP Digital Manufacturing,

- SAP Manufacturing Execution

Labels:

6 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- Quick Start guide for PLM system integration 3.0 Implementation in Product Lifecycle Management Blogs by SAP

- Striking the Perfect Balance in Product Lifecycle Management Blogs by SAP

- MII configuration and content transport management in Product Lifecycle Management Blogs by SAP

- 2024 SAP Digital Manufacturing Assets: IVJs, videos and blog posts in Product Lifecycle Management Blogs by SAP

- SAP Digital Manufacturing and SAP MII integration in Product Lifecycle Management Q&A