- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Capacity Planning (Leveling) and Evaluation in S4H...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

kraghavanbindhu

Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-18-2023

2:37 PM

Introduction

Hi All,

In this blog we will see the capactiy leveling and evaluation.

Capacity evaluation is just a monitor to see weather all the resource/ workcenters are available or not.

Capacity leveling is moving the orders from one date to other if the capacity is not available or overloaded.

Before that why we need capacity apps in PP?

In APO all the materials will be planned by considering all the operation time and workcenters as finite capacity in MRP itself. So all production orders will be created by considering the capacity accurately (Work hours, Break time, shift time, relationship time, inter operation time, Splits). Here we are in no need of Capacity planning.

But in PP all the materials are planned by considering all the oepration time and workcenters as infinite capacity in MRP. so the system will not consider the capacity accurately. So the production orders will be created without considering the capacity. The operation times are considered only per order per material. For a material all orders will be created on same day. Since we need to do capacity leveling again in PP system.

This is why because APO is only for Planning (MRP) and PP is only for execution (Confirmation, GI, GR).

Finite Capacity - Moudling machine which can handle certain amount of product on a day

Infinite capacity - Cooling sillo which can cool enormous amount of air on a day

Main Part

Master data.

BOM - 1 finished material Magazine need 1 raw material plastic of 1 KG

Resource / Workcenter - MOULD with 24 working hrs per day

Capacity Formulas to be maintained.

Routing - Here I mentioned 24 hrs for making 1 magazine.

As per the above master data we can manufacture only one magazine per day as the machine MOULD can work 24 hrs a day.

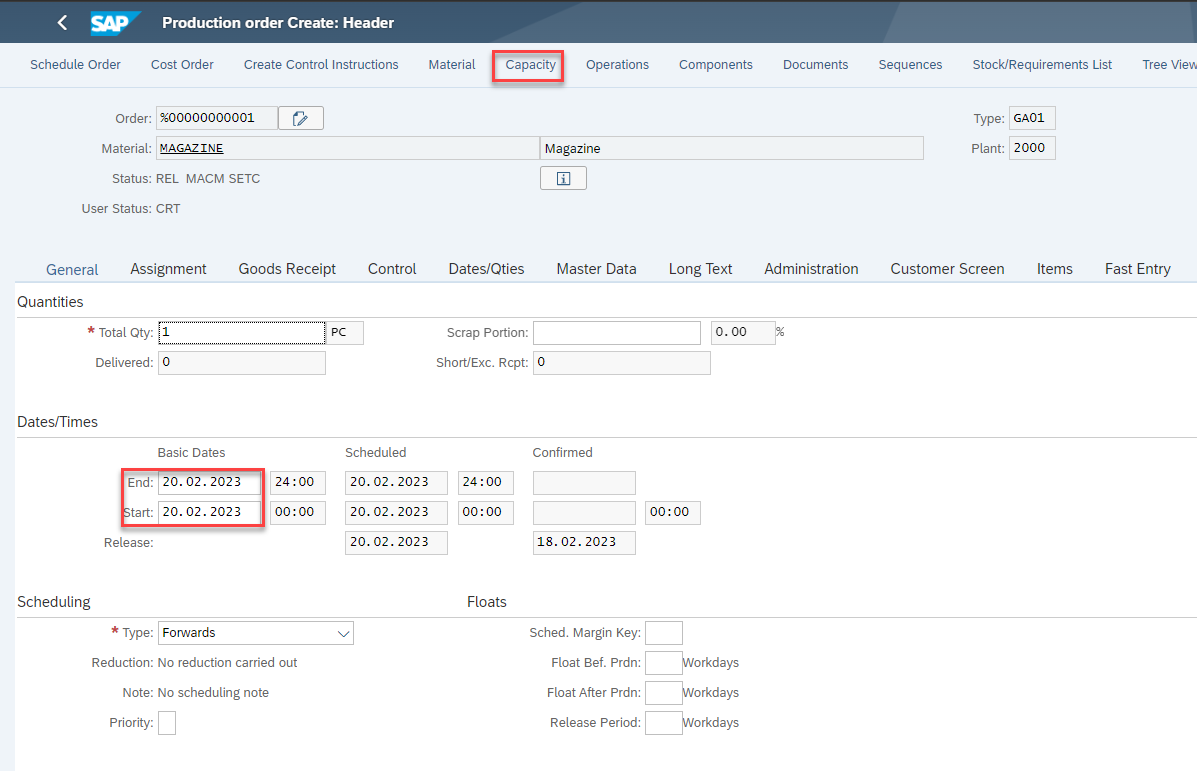

Creating one production order for 1 quantity.

I am using forward scheduling and starting on 20.02.2023. As per above statement it take 1 day to produce one magazine and the production gets ended by 20.02.2023.

Capacity Evaluation

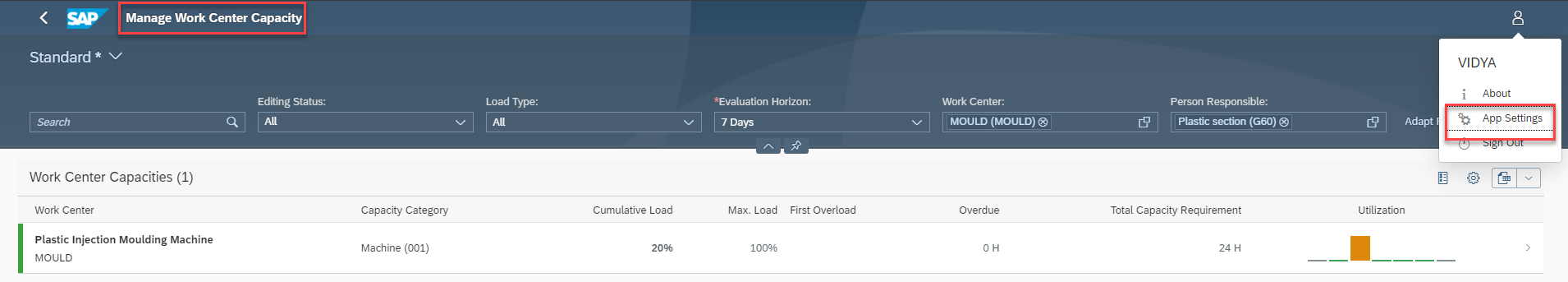

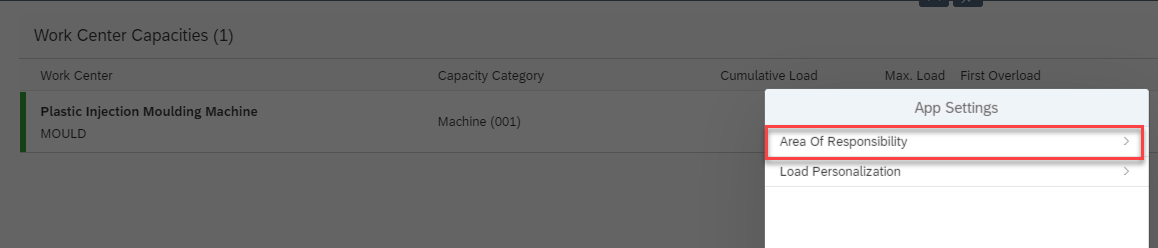

Now we will see the app manage work center capacity app

At first maintain the area of responsibility in app settings. Otherwise workcenter will not be visible here.

Here in this app we could able to see one production order on date 20.02.2023. The color is amber as the capacity is fully utilized. If its red then overload and green means then under load.

Now I am creating another order on same day 20.03.2023

You may expect the new order should start by next date 21.02.2023, since we have capacity check in production order screen and we already have one order on 20.02.2023.

But PP system will not schedule the orders by considering the capacity by itself. If the order needs to schedule to next day you need to go to capacity planning table for evaluating the capacity condition and to put the schedule start data on next available capacity date.

But this will also not be possible in FIORI if you are using grand chart capacity evaluation profile.

Side by side you can use Monitor work center schedule apps for clear understanding. Here also assign the area of responsibility in app settings.

It will not be possible to do the scheduling one by one. So we have an app to see all the capacity overloads and its Manage work center capacity.

Now save the production order and go to Manage workcenter capacity app.

As two orders scheduled on same day the evaluation app shows overload. Now capacity evaluation is done.i.e we have realised that there are some overload in workcenter. Now we have to reduce the overlaod. So we have to either delete or reschedule the production order.

Also you can use the Monitor workcenter schedules app to get the detailed view.

Here you can see two orders scheduled on same day.

(Click arrow mark near work center to see the no of orders on same workcenter)

Capacity Leveling

To reduce the overload we need to use shcedule production app

To see the data in schedule production app we need to mention bottleneck workcenter (workcenter which takes the longest time - lead time with in the routing) in production version as production line. This can be mentioned in C223. i.e. production version.

Bottle neck workcenter means the workcenter which takes the longest time among other workcenters in the routing of finished material. Here I am using only one workcenter so i have mentioned it.

This app should be configured first and to configure this app please follow this link https://blogs.sap.com/2022/09/21/schedule-production-app-or-capacity-scheduling-board-runtime-error-...

Here also we have to maintain the person responsibility and strategy.

Inside Strategy you need to maintain the scheduling and industry type.

Below you can see the two order which we have created and all are not dispatched. i.e not yet confirmed by capacity planned to start the production.

So here system will automatically check the capacity and reshedule the orders, so that the overload will be reduced.

After dispatch you can see the status as dispatched.

Now capacity leveling is done.

Now we will do the capacity evaluation again to confirm that all the overloads has been cleared in workcenters or not.

Here you can see that the two orders has been scheduled next to next days based on capacity availability.

Same you can see in Monitor workcenter schedules app.

Now the capacity evaluation done.

Conclusion.

I hope this may help you on knowing the capacity evaluation and leveling

Would like you guys to see more relevant things using the link:

https://blogs.sap.com/2020/09/07/why-capacity-requirement-planning-is-integral-to-production-plannin...

We would very much appreciate your comments and suggestions below.

You can use CM40 to schedule the Orders in background and in mass.

Hi All,

In this blog we will see the capactiy leveling and evaluation.

Capacity evaluation is just a monitor to see weather all the resource/ workcenters are available or not.

Capacity leveling is moving the orders from one date to other if the capacity is not available or overloaded.

Before that why we need capacity apps in PP?

In APO all the materials will be planned by considering all the operation time and workcenters as finite capacity in MRP itself. So all production orders will be created by considering the capacity accurately (Work hours, Break time, shift time, relationship time, inter operation time, Splits). Here we are in no need of Capacity planning.

But in PP all the materials are planned by considering all the oepration time and workcenters as infinite capacity in MRP. so the system will not consider the capacity accurately. So the production orders will be created without considering the capacity. The operation times are considered only per order per material. For a material all orders will be created on same day. Since we need to do capacity leveling again in PP system.

This is why because APO is only for Planning (MRP) and PP is only for execution (Confirmation, GI, GR).

Finite Capacity - Moudling machine which can handle certain amount of product on a day

Infinite capacity - Cooling sillo which can cool enormous amount of air on a day

Main Part

Master data.

BOM - 1 finished material Magazine need 1 raw material plastic of 1 KG

Resource / Workcenter - MOULD with 24 working hrs per day

Capacity Formulas to be maintained.

Routing - Here I mentioned 24 hrs for making 1 magazine.

As per the above master data we can manufacture only one magazine per day as the machine MOULD can work 24 hrs a day.

Creating one production order for 1 quantity.

I am using forward scheduling and starting on 20.02.2023. As per above statement it take 1 day to produce one magazine and the production gets ended by 20.02.2023.

Capacity Evaluation

Now we will see the app manage work center capacity app

At first maintain the area of responsibility in app settings. Otherwise workcenter will not be visible here.

Here in this app we could able to see one production order on date 20.02.2023. The color is amber as the capacity is fully utilized. If its red then overload and green means then under load.

Now I am creating another order on same day 20.03.2023

You may expect the new order should start by next date 21.02.2023, since we have capacity check in production order screen and we already have one order on 20.02.2023.

But PP system will not schedule the orders by considering the capacity by itself. If the order needs to schedule to next day you need to go to capacity planning table for evaluating the capacity condition and to put the schedule start data on next available capacity date.

But this will also not be possible in FIORI if you are using grand chart capacity evaluation profile.

Side by side you can use Monitor work center schedule apps for clear understanding. Here also assign the area of responsibility in app settings.

It will not be possible to do the scheduling one by one. So we have an app to see all the capacity overloads and its Manage work center capacity.

Now save the production order and go to Manage workcenter capacity app.

As two orders scheduled on same day the evaluation app shows overload. Now capacity evaluation is done.i.e we have realised that there are some overload in workcenter. Now we have to reduce the overlaod. So we have to either delete or reschedule the production order.

Also you can use the Monitor workcenter schedules app to get the detailed view.

Here you can see two orders scheduled on same day.

(Click arrow mark near work center to see the no of orders on same workcenter)

Capacity Leveling

To reduce the overload we need to use shcedule production app

To see the data in schedule production app we need to mention bottleneck workcenter (workcenter which takes the longest time - lead time with in the routing) in production version as production line. This can be mentioned in C223. i.e. production version.

Bottle neck workcenter means the workcenter which takes the longest time among other workcenters in the routing of finished material. Here I am using only one workcenter so i have mentioned it.

This app should be configured first and to configure this app please follow this link https://blogs.sap.com/2022/09/21/schedule-production-app-or-capacity-scheduling-board-runtime-error-...

Here also we have to maintain the person responsibility and strategy.

Inside Strategy you need to maintain the scheduling and industry type.

Below you can see the two order which we have created and all are not dispatched. i.e not yet confirmed by capacity planned to start the production.

Now the capacity planned need to select all the production order and to dispatch the orders so that the operators can start the production and to reduce the overload. After dispatching we need to save the orders. Otherwise the changes will not be saved.

So here system will automatically check the capacity and reshedule the orders, so that the overload will be reduced.

After dispatch you can see the status as dispatched.

Now capacity leveling is done.

Now we will do the capacity evaluation again to confirm that all the overloads has been cleared in workcenters or not.

Here you can see that the two orders has been scheduled next to next days based on capacity availability.

Same you can see in Monitor workcenter schedules app.

Now the capacity evaluation done.

Conclusion.

I hope this may help you on knowing the capacity evaluation and leveling

Would like you guys to see more relevant things using the link:

https://blogs.sap.com/2020/09/07/why-capacity-requirement-planning-is-integral-to-production-plannin...

We would very much appreciate your comments and suggestions below.

You can use CM40 to schedule the Orders in background and in mass.

3 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- SAP S/4HANA Cloud Extensions with SAP Build Best Practices: An Expert Roundtable in Enterprise Resource Planning Blogs by SAP

- SAP Fiori for SAP S/4HANA – Upgrade Faster – Managing app lifecycle impacts on users in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Public Edition - Tips and Tricks in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Public Edition 后勤常见热点问题汇总FAQ in Enterprise Resource Planning Blogs by SAP

- Product Compliance in SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |