- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by Members

- SAP Manufacturing Execution – Sampling process

Product Lifecycle Management Blogs by Members

Get insider knowledge about product lifecycle management software from SAP. Tap into insights and real-world experiences with community member blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Sajeesh

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-15-2023

8:14 PM

Hello Everyone,

SAP Manufacturing Execution (SAP ME) has some very powerful features that allows you to perform in the manufacturing process.

I would like to share the Sampling feature that allows you to detect possible process problems and identify nonconforming product early in the manufacturing process to prevent excess rework or scrap cost. In this blog post, you will find valuable notes related to the basic configuration for Sampling Process in SAP ME.

High Level Overview

Detailed Steps:

Step 1: Routing Maintenance

Step 2: Sample Plan Maintenance

Step 3: NC Code Maintenance

Step 4: Data Collection Maintenance

Step 5: Shop Order Maintenance

Step 6: Shop Order Release

Step 7: POD SFC

Step 8: SFC Group Report

Conclusion

The above process summarizes the understanding of the Sampling process, and I hope that you all understand it.

Thank you for reading the blog post and stay tuned! to learn more about SAP Manufacturing and Execution.

For further questions related to the blog, please check the Q&A area, and feel free to post your questions and feedback.

SAP Manufacturing Execution (SAP ME) has some very powerful features that allows you to perform in the manufacturing process.

I would like to share the Sampling feature that allows you to detect possible process problems and identify nonconforming product early in the manufacturing process to prevent excess rework or scrap cost. In this blog post, you will find valuable notes related to the basic configuration for Sampling Process in SAP ME.

High Level Overview

- Routing Maintenance.

- Sample Plan Maintenance

- NC Code Maintenance.

- Data Collection Maintenance

- Shop Order Maintenance

- Shop Order Release

- POD SFC

- SFC Group Report

Detailed Steps:

Step 1: Routing Maintenance

- Created Production Routing.

- Created Sample Routing

- Sample Routing layout

Step 2: Sample Plan Maintenance

- Created Sample plan - Type: Custom, attach Sample Routing - NC Severity Threshold

- In Details tab, capture the SFC Group Size and Sample fixed number,

Accept and Reject numbers.

- In the Attached tabà Material and Operation assigned

Step 3: NC Code Maintenance

- Created NC Code and assigned the NC data type to collect the defect count.

NC Severity for the NC Code

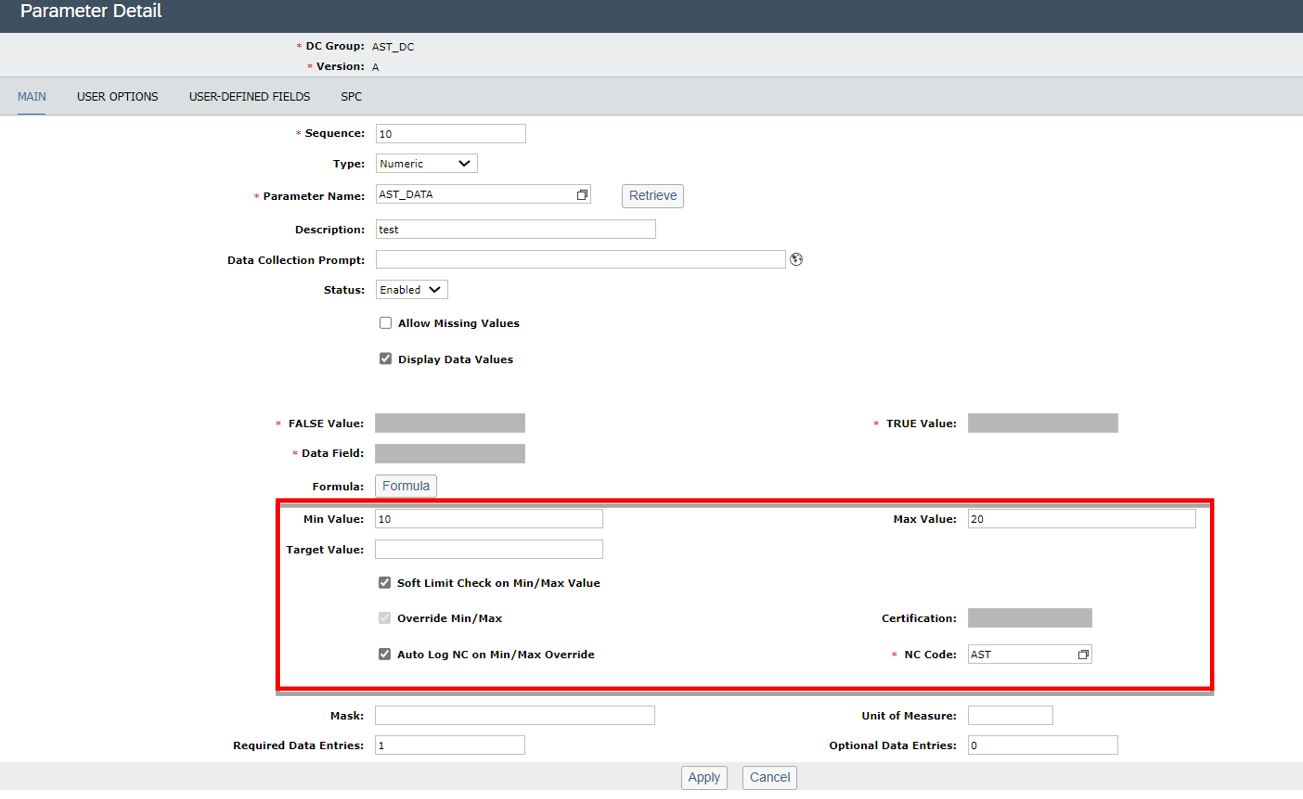

Step 4: Data Collection Maintenance

- Created DC Group (AST_DC)

- In the Attached tab assign the operation where the data to be collected.

- Added parameter details the min and max value added, soft limit check

enabled, the Auto log NC is also enabled and attached the NC Code.

Step 5: Shop Order Maintenance

- Created the Shop Order(Production Order) in S4 or ME.

Step 6: Shop Order Release

- Released the shop order(Production Order) with 20 qty à SFC generated.

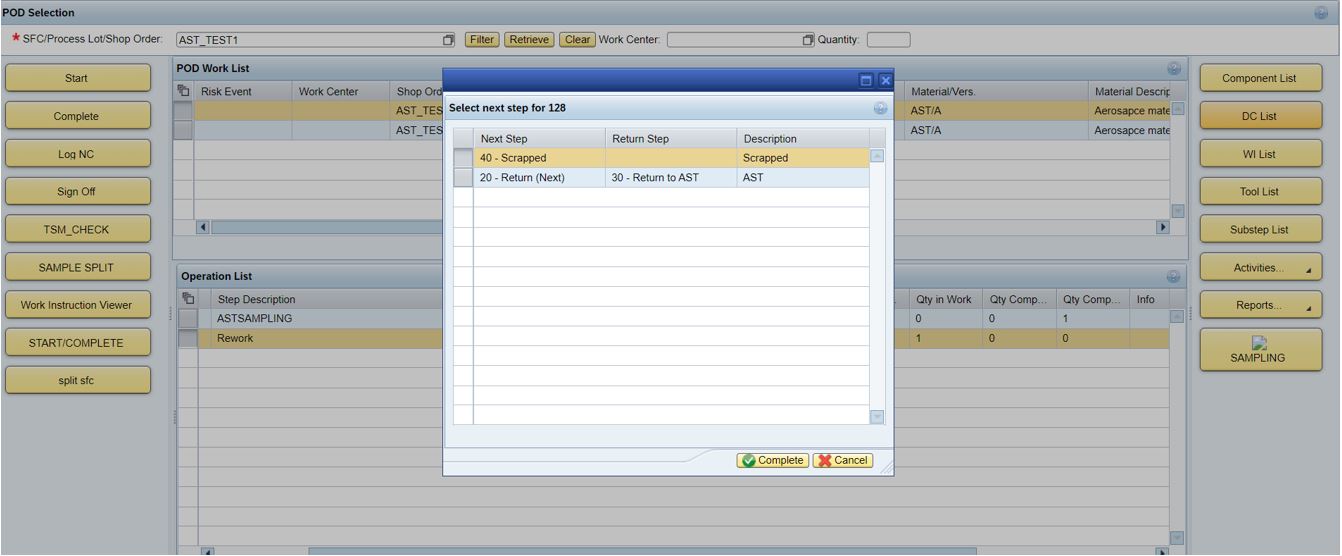

Step 7: POD SFC

- In POD the 1st Operation is completed and the 2nd Operation be processed.

- The 2nd Operation is Started and the SFC will be in Complete pending status

at the Second operation until the sample is processed. Click on SAMPLING.

- The SFC Group number generated, the sample qty is split based on the fixed number,

new Sample SFC is generated. Click OK to proceed.

- The Original SFC will be in hold until the Sample SFC is processed.

The Sample operation is started and the DC value is collected with outside of the min/max value.

- The alert message is displayed to enter the defect Count.

- The Data collected is saved confirming the outside value.

- The NC Code is logged and the defect Count qty is updated. Click on Add – Done.

- After the NC is logged the SFC is Dispositioned to Rework or Next(ASTPACKING)

Operation. Selected REWORK Operation and click Continue.

- After the Rework is processed the Sample SFC is sent to Next operation or

Scrapped based on the inspection.

- The Sample SFC Qty is Scrapped and the SFC group is rejected.

Step 8: SFC Group Report

- The Sample status can be viewed in the SFC Group Report using the parameters

Conclusion

The above process summarizes the understanding of the Sampling process, and I hope that you all understand it.

Thank you for reading the blog post and stay tuned! to learn more about SAP Manufacturing and Execution.

For further questions related to the blog, please check the Q&A area, and feel free to post your questions and feedback.

- SAP Managed Tags:

- SAP Manufacturing Execution

4 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- Issue while Inspection Results Recording in DMC in Product Lifecycle Management Q&A

- SAP Digital Manufacturing: Embed Digital Manufacturing in Custom Web Apps in Product Lifecycle Management Q&A

- Extending SAP Digital Manufacturing with Azure, Part II: Applying the reference architecture to a visual inspection scenario in Product Lifecycle Management Blogs by Members

- Extending SAP Digital Manufacturing with Azure, Part I: Reference architecture in Product Lifecycle Management Blogs by Members

- Maximizing Profitability: Increase Re-Use in the Discrete Industry in Product Lifecycle Management Blogs by SAP