- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Correcting the Confirmed Quantity after Putaway us...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

If the same product is supplied by multiple supplier then it will become a tedious task to identify the discrepancy.

This blog post provides a high-level overview of the confirmation correction functionality after the completion the putaway task.

The system allows the user to modify/update the quantity received using the confirmed warehouse task using the handheld device or the standalone GUI transaction code if the time delay has not exceeded. If the time delay set up has exceeded then the system changes the status of the delivery to the 'DCO' and sends the GR information to the ECC/ERP system.

EWM delays sending a warehouse task that has already been confirmed, corresponding to the completion delay you have specified for inbound deliveries in Customizing. In accordance with the completion delay, you can still correct the actual quantity for the destination storage bin and the batch. You make your correction and specify an exception code in the warehouse task for each delivery item.

When the completion delay has exceeded, the EWM system sets the status DWM

for sending the completion indicator to Completed

. By doing this, EWM also indirectly sets the completion status DCO

for the inbound delivery to Completed

. Once the completion status DCO

for an inbound delivery has status value Completed, then

EWM system initiates the goods movement activities in the ERP system. The system won't allow to make any corrections in the confirmed warehouse task.

The report /SCWM/R_PRDI_SET_DWM is used to set the status DWM

for sending the completion indicator to Completed. When the confirmation correction activity is performed the system automatically creates a background job using the job delay with the released status. The job gets processed according to the schedule.

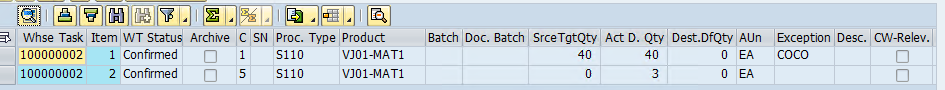

The confirmation correction activity uses the exception code called 'COCO' to allow the changes to the document.

Note – All the steps were configured and tested on SAP S/4 2021 Embedded system.

Deployments:

- Decentralized EWM and Embedded initial release onwards

- Application Component – SCM-EWM-WOP-BF-CC

Steps:

- Activation of the status 'DWM' - IMG Path - SPRO–IMG-SCM Extended Warehouse Management-Extended Warehouse Management-Cross-Process Settings-Delivery Processing-Status Management-Define Status Profiles

Active Status

- Define Delay in Completion of Inbound Deliveries - SPRO–IMG-SCM Extended Warehouse Management-Extended Warehouse Management- Goods Receipt Process- Inbound Delivery- Define Delay in Completion of Inbound Deliveries

Note:

Tolerance for Completion - Sets the 'DCO' status for several items simultaneously, EWM collects all completed items for which EWM has set the DWA status to Completed within this time. The time for the tolerance must be smaller than the completion delay.

Delay in Job Rescheduling for Setting DWM Status - Delay in rescheduling a background job for the job to set the 'DWM' indicator. If EWM cannot set the DWM status within the background job, EWM schedules a new job. If you do not specify your own value, EWM uses the default value of 120 seconds

- Exception Code 'COCO' Set up - Make sure that the exception code 'COCO' is active for the warehouse.

Note: Make the required settings for the exception code 'COCO' if not available.

Testing

- Case 1 - Confirmed quantity is more than the inbound delivery quantity.

- Create a Purchase order and a subsequent delivery for the PO.

ERP Inbound delivery

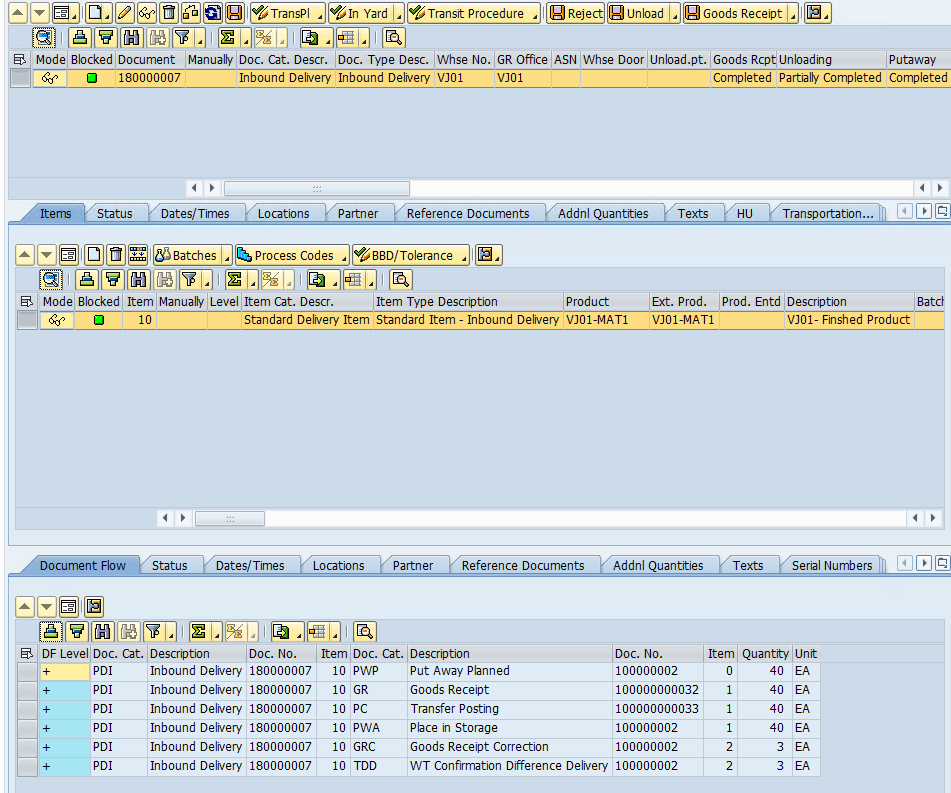

EWM Inbound Delivery

- Create the warehouse task for the product. In this step, we are not packing the product and there are no HUs associated with.

- Confirm the warehouse task.

- Verify the background job scheduled to set the completion status.

- Now Update received/GR quantity by editing the confirmed warehouse task.

![]()

Update the quantity and the exception code. Save it

The below message will be displayed.

The document flow of the inbound delivery gets updated.

- The inbound delivery document status before the execution of the background job.

- The warehouse task details.

- The warehouse task details.

- Upon execution of the job, the ERP delivery document gets updated with the quantity received via goods movement.

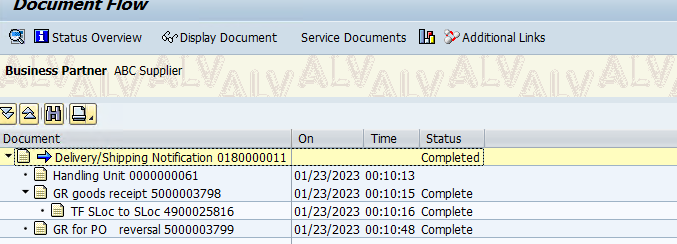

- The document flow of the inbound delivery in ERP.

- Case 2 - If the received quantity is less than the order quantity, then the system will create a reversal document.

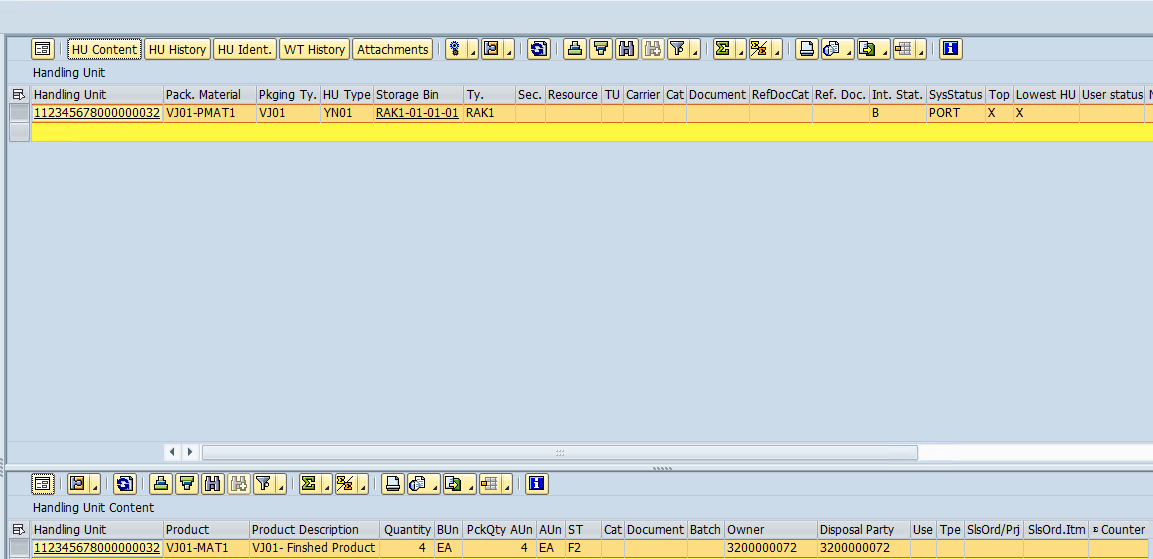

- Case 3 - HU Based Warehouse Task-

- Received more than delivery item quantity

- Received less than delivery item quantity

HU Contents

The above activities can be performed using the RF/handheld devices as well.

Useful Links:

S4 HANA 2021 – Confirmation Correction | SAP Help Portal

S4 HANA 2022 - Confirmation Correction | SAP Help Portal

EWM 9.5 - Confirmation Correction | SAP Help Portal

Confirmation Correction Using Radio Frequency

Limitations:

- If the system time and the warehouse time are different, then the background job may give a dump during the release of the job created.

Conclusion:

With this process improvement, the warehouse operations can be optimized and the inventory in both the systems match. This will also help to keep the stock in sync between the systems.

Do you have any further comments related to this topic? Do share them in the comments sections below without any hesitation. You can also ask questions in the SAP EWM Goods Movement Community Q & A Section

Note – All the images are created by me and free to use/share

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- EWM - Delivery Processing,

- EWM - Goods Movement

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- SAP Business Network for Logistics 2402 Release – What’s New? in Supply Chain Management Blogs by SAP

- Updates the consumption values an Corrected values automatically in Supply Chain Management Q&A

- Correction on a MIGO Goods issue in Supply Chain Management Q&A

- SAP EWM Check Monitor Framework – How to correct Warehouse Order status related issues in Supply Chain Management Blogs by SAP

- How to Cancel GR posting from COGI in Supply Chain Management Q&A

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |