- SAP Community

- Products and Technology

- Technology

- Technology Blogs by SAP

- P2P : Delivery times for Purchase Orders - or what...

Technology Blogs by SAP

Learn how to extend and personalize SAP applications. Follow the SAP technology blog for insights into SAP BTP, ABAP, SAP Analytics Cloud, SAP HANA, and more.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-21-2022

7:02 PM

Most SAP Customers run Procure to Pay processes, be it for indirect or direct materials.

I observe that most customers face supply chain issues due to incorrectly material master settings. These settings heavily impact manual efforts on the Purchase Requisition (PR) to Purchase Order (PO) flow, but also on Safety Stock Levels ( and therefore Liquidity).

I want to show that focusing on 'Planned Delivery Times' on the Material master (MARC-PLIFZ) will have extremely positive effects, and all that is needed is SAP Process Insights.

In Detail

For MRP driven materials several settings on the material master determine when a PR gets created, and for which suggested quantity based on a current 'Supply / Demand' situation present during the MRP run.

I want to put focus on direct materials, in particular Purchase Orders that were created as a result of an MRP run for materials with Procurement Type 'F' ( the German 1st character for 'Fremd' / 'External).

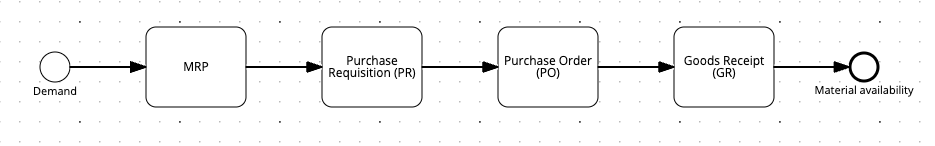

Below you see the logical flow of events.

The MRP run calculates Quantity and Date, iow, it suggests something like :

Order quantity X of material A on date D

I would like to elaborate a bit on how date D is calculated (simplified).

😧 PR Creation Date =

(Demand Date) - (Goods Receipt Processing Time) - (Planned Delivery Time) - (PR Processing)

If everything is well maintained, and the supplier delivers as expected, we should expect a goods receipt on time.

But this is not what I observe in customer systems.

Below illustration shows the gap between 'theory' and 'reality'

In fact, we typically find the following

This means, that MRP induced POs do not deliver reliably and robustly.

How to improve the precision of PO deliveries?

There are many explanations why reality does hardly represent theory.

But significant improvement can be achieved by optimising at the planned delivery times maintained on plant level for externally procured materials.

SAP Process Insights delivers fantastic, actionable Insights with just a few clicks.

Choose your Purchase Requisition to Purchase Order Flow

Here, we want to focus on MRP created PRs, so select the filter 'Creation Ind. ESTKZ' = 'B'

Select your filter so that you focus on Raw Materials ( e.g. by Document Type or similar).

Now choose the filter 'Pl. Deliv. Time(Mat) PLIFZ_MARC' as well as 'Pl. Deliv. Time(PR) PLIFZ'

Sort both by 'ID', you should see something like this:

To the left you see 'Number of Days', and on the right you see how many PR Items were created in the time period for with this Number.

By putting both filters next to each other, you see on the left column what the system was using during MRP, and on the right column you see the value on the PR after manual intervention.

Do you see the difference?

But more interestingly is below is when you focus on '5' and '10'... - or on '7' and '14' ....

You see that in this example, there are two interpretations of 'what is a week?'.

The team that chooses '7' btw is correct.

Let's take an example : The Supplier tells has he can typically deliver in 6 weeks.

This means, that the MRP job is creating the Purchase Requisitions 12 days too late. If the rest of the process happens as expected, production must be delayed by such 12 days. (In theory)

You can btw also measure the actual delivery time with process insights.

Without going further, here is what you should take away

While certainly not all answers to improve Supply are in you area of influence - focusing on planned delivery times will bring great value to the organisation.

You can start with the 'What's a week' Analysis as indicated above, your one time usage right of SAP SIGNAVIO Process Insights from your RISE Contract is sufficient.

What is your experience with 'planned delivery times?'

Feel free to reach out to me to explore your data, to discuss and feedback, and, make sure to follow SAP SIGNAVIO.

I observe that most customers face supply chain issues due to incorrectly material master settings. These settings heavily impact manual efforts on the Purchase Requisition (PR) to Purchase Order (PO) flow, but also on Safety Stock Levels ( and therefore Liquidity).

I want to show that focusing on 'Planned Delivery Times' on the Material master (MARC-PLIFZ) will have extremely positive effects, and all that is needed is SAP Process Insights.

In Detail

For MRP driven materials several settings on the material master determine when a PR gets created, and for which suggested quantity based on a current 'Supply / Demand' situation present during the MRP run.

I want to put focus on direct materials, in particular Purchase Orders that were created as a result of an MRP run for materials with Procurement Type 'F' ( the German 1st character for 'Fremd' / 'External).

Below you see the logical flow of events.

The MRP run calculates Quantity and Date, iow, it suggests something like :

Order quantity X of material A on date D

I would like to elaborate a bit on how date D is calculated (simplified).

😧 PR Creation Date =

(Demand Date) - (Goods Receipt Processing Time) - (Planned Delivery Time) - (PR Processing)

If everything is well maintained, and the supplier delivers as expected, we should expect a goods receipt on time.

But this is not what I observe in customer systems.

Below illustration shows the gap between 'theory' and 'reality'

In fact, we typically find the following

- The planned delivery time on the Material master is never equal the actual delivery time

- The Purchase Orders are typically not created on the suggested date

- If people adjust the delivery date on the PR to a value different from the material master, it also does not hold true

This means, that MRP induced POs do not deliver reliably and robustly.

How to improve the precision of PO deliveries?

There are many explanations why reality does hardly represent theory.

But significant improvement can be achieved by optimising at the planned delivery times maintained on plant level for externally procured materials.

SAP Process Insights delivers fantastic, actionable Insights with just a few clicks.

Choose your Purchase Requisition to Purchase Order Flow

Here, we want to focus on MRP created PRs, so select the filter 'Creation Ind. ESTKZ' = 'B'

Select your filter so that you focus on Raw Materials ( e.g. by Document Type or similar).

Now choose the filter 'Pl. Deliv. Time(Mat) PLIFZ_MARC' as well as 'Pl. Deliv. Time(PR) PLIFZ'

Sort both by 'ID', you should see something like this:

To the left you see 'Number of Days', and on the right you see how many PR Items were created in the time period for with this Number.

By putting both filters next to each other, you see on the left column what the system was using during MRP, and on the right column you see the value on the PR after manual intervention.

Do you see the difference?

But more interestingly is below is when you focus on '5' and '10'... - or on '7' and '14' ....

You see that in this example, there are two interpretations of 'what is a week?'.

One group believes you should take 5 days, another believe to take 7 days.

The team that chooses '7' btw is correct.

Let's take an example : The Supplier tells has he can typically deliver in 6 weeks.

- Group 1 calculates 6*5 days = 30 Days

- Group 2 calculates 6*7 days = 42 Days

This means, that the MRP job is creating the Purchase Requisitions 12 days too late. If the rest of the process happens as expected, production must be delayed by such 12 days. (In theory)

You can btw also measure the actual delivery time with process insights.

Without going further, here is what you should take away

- SAP SIGNAVIO Process Insights helps you understand the real size of the opportunity

- Planned Delivery Times on material masters are typically insufficiently accurately maintained

- Generating a common understanding of '7 days = 1 week', with a subsequent update of Material Masters hardens the recommendations from MRP and improves the Supply of raw materials

- Well maintained Planned Delivery times positively impact the reduction of Safety Stocks

- Improving material master data allows to increase efficiency, automation, and provides more time for MRP controllers to focus on the unplanned

While certainly not all answers to improve Supply are in you area of influence - focusing on planned delivery times will bring great value to the organisation.

You can start with the 'What's a week' Analysis as indicated above, your one time usage right of SAP SIGNAVIO Process Insights from your RISE Contract is sufficient.

What is your experience with 'planned delivery times?'

Feel free to reach out to me to explore your data, to discuss and feedback, and, make sure to follow SAP SIGNAVIO.

- SAP Managed Tags:

- SAP Signavio,

- SAP Signavio Process Insights

Labels:

8 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

ABAP CDS Views - CDC (Change Data Capture)

2 -

AI

1 -

Analyze Workload Data

1 -

BTP

1 -

Business and IT Integration

2 -

Business application stu

1 -

Business Technology Platform

1 -

Business Trends

1,658 -

Business Trends

93 -

CAP

1 -

cf

1 -

Cloud Foundry

1 -

Confluent

1 -

Customer COE Basics and Fundamentals

1 -

Customer COE Latest and Greatest

3 -

Customer Data Browser app

1 -

Data Analysis Tool

1 -

data migration

1 -

data transfer

1 -

Datasphere

2 -

Event Information

1,400 -

Event Information

66 -

Expert

1 -

Expert Insights

177 -

Expert Insights

299 -

General

1 -

Google cloud

1 -

Google Next'24

1 -

Kafka

1 -

Life at SAP

780 -

Life at SAP

13 -

Migrate your Data App

1 -

MTA

1 -

Network Performance Analysis

1 -

NodeJS

1 -

PDF

1 -

POC

1 -

Product Updates

4,577 -

Product Updates

345 -

Replication Flow

1 -

RisewithSAP

1 -

SAP BTP

1 -

SAP BTP Cloud Foundry

1 -

SAP Cloud ALM

1 -

SAP Cloud Application Programming Model

1 -

SAP Datasphere

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Migration Cockpit

1 -

Technology Updates

6,873 -

Technology Updates

427 -

Workload Fluctuations

1

Related Content

- SAP Build Process Automation Pre-built content for Finance Use cases in Technology Blogs by SAP

- Demystifying the Common Super Domain for SAP Mobile Start in Technology Blogs by SAP

- How to send email in SAP S/4 HANA Cloud public on creation of Purchase order to approve in Technology Q&A

- Unify your process and task mining insights: How SAP UEM by Knoa integrates with SAP Signavio in Technology Blogs by SAP

- Data Proposal for Sales Order Requests - Determination with Reference to Order Creation History in Technology Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 40 | |

| 25 | |

| 17 | |

| 14 | |

| 8 | |

| 7 | |

| 7 | |

| 7 | |

| 6 | |

| 6 |