- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- SAP Service and Asset Manager 2210 Now Available –...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-31-2022

5:41 PM

Our latest release affirms our commitment to delivering innovation requests from our customers and partners. Our Customer Influence portal has become a valuable tool when planning new features, and this release delivers five of those requests.

We encourage you to learn more about How Customers and Partners Can Submit Improvement Requests and Influence Future Releases of SAP Serv.... The customer requests and other new features translate to improved efficiency for our maintenance, field service, and inventory users.

The customer requests and other new features translate to improved efficiency for our maintenance, field service, and inventory users.

Please read on to learn more.

Offline applications allow technicians to carry out work anywhere, a very important requirement. In today’s world, plants have wi-fi coverage and cellular network connections are common and fast.

Customers may now enable auto-synchronization based on mobile client events. The Mobile Application Integration Framework Configuration, a.k.a. the ConfigPanel, provides options to trigger synchronization for the following:

You may enable one or more of these options to suit your preferences.

Smartforms† provide a script for service execution, ensuring that technicians have the right script for the right scenario. A solution from SAP Field Service Management, Smartforms are managed in the Smartforms and Feedback app.

This integration allows the mobile client to download, modify, and upload Smartforms. These can be dynamic, multi-step forms used to capture safety data, inspections results, notes and much more.

All of us value consistency in service; a service script for technicians will promote efficiency and consistency.

Production orders use inbound and outbound procedures, by issuing components (raw materials) for the order production process, and then receiving those finished items into stock.

The production order screen includes tabs for the components, items, and the related material documents. The inventory clerk can easily see the details of each and initiate issuing and receiving right from the list.

The inventory clerk persona now supports reversal movement types 102 and 122.

The goods receipt reversal movement (102) is used to remedy an incorrect posting, perhaps the materials were received against the wrong order and it needs to be corrected. The return to vendor movement (122) is used, for example, when materials arrive damaged and must be returned to the vendor.

A great user experience improvement, completion screens are now consolidated into one screen. Previously, the user would see a series of windows for time confirmation, notes, signature, etc.

It is common for multiple objects to have the same location, selecting them on a map can be difficult. It is now much easier to select collocated and overlapping objects on the map.

Tapping on a group of pins, will display a list of all the objects in the group. You may then select one from the list, to view more details.

Long text templates are managed in the backend and serve as an outline to collect notes. For example, the template may instruct the user to “Please give the details of damaged part:”.

Technicians may access a template when entering notification details.

As we saw above, when reporting a malfunction it is important to gather good details to understand the issue. Event prioritization is a tool the technician may use to assess the priority of the notification. The feature allows you to select consequences and likelihoods in case of the failure of an equipment.

For example, a maintenance technicians observes an oil leak and wants to report this as a malfunction. The event prioritization feature suggests a very high priority because the equipment is critical to plant operations, and if it is not repaired within two weeks, it could damage the asset.

When working with vehicle stock, it’s nice to see the parts that I will need for today’s orders. We added a “Needed for Today” filter to the Vehicle Stock Lookup list to give technicians another tool to find what they need easily.

Order, notification, and operation detail screens show system and user statuses; technicians see additional context on the state of the item

The operation details now include the number of techs assigned along with the planned duration, including the time per technician. It is common to capture a reason for time variance against the planned value so it helps the technician to know the planned duration for that operation.

To quote the customer request, this feature will "help the technician to plan the tasks and also as a reference in the time entries."

Our list views now show the Technical Identification number, as this is often used as the primary ID by technicians when looking up equipment. The value is available via searching and scan as well. and is displayed in the header on the object page.

A small but useful feature, a technician may now view long text for Production Resource/Tool (PRT) items. The text is shown as a note on the PRT equipment page.

Adds Vietnamese; 29 languages supported.

The application is publicly available and includes an offline demo mode for viewing and testing the extensive functionality with maintenance technician, field service technician and inventory clerk personas included.

The application metadata is now available on the SAP Support Portal Software Center and the mobile client may be downloaded from the Apple App Store and Google Play Store.

* SAP Customer Influence request

† SAP Field Service Management is licensed separately; Smartforms is not included with SAP Service and Asset Manager.

‡ Only available with S/4HANA

We encourage you to learn more about How Customers and Partners Can Submit Improvement Requests and Influence Future Releases of SAP Serv....

The customer requests and other new features translate to improved efficiency for our maintenance, field service, and inventory users.

The customer requests and other new features translate to improved efficiency for our maintenance, field service, and inventory users.Please read on to learn more.

Table of contents

- Key features delivered in the 2210 release

- Auto-synchronization

- SAP Field Service Management Smartforms integration

- Goods movement for production orders

- Reversal of goods movement

- Consolidated completion screens

- Aggregated items on map

- Additional features

- Enable Long Text Templates

- Include Event Prioritization

- Filter parts by “Needed for Today”

- Show system and user statuses

- Show planned duration and number of technicians

- Display Technical Object ID

- Display master PRT long text

- Language support

- Release available now

Key features delivered in the 2210 release

Auto-synchronization*

Offline applications allow technicians to carry out work anywhere, a very important requirement. In today’s world, plants have wi-fi coverage and cellular network connections are common and fast.

Customers may now enable auto-synchronization based on mobile client events. The Mobile Application Integration Framework Configuration, a.k.a. the ConfigPanel, provides options to trigger synchronization for the following:

| On database save | Auto-sync after every save to the local mobile database, e.g., add an attachment, record results, and much more |

| On status change | Auto-sync after any change to the mobile status, e.g., accept order, start order |

| On foreground | Auto-sync when the app becomes active on the device, e.g., app is launched, user switched to email app and then comes back |

| On connection change | Auto-sync when the mobile device goes from offline to online |

| Periodic | Auto-sync periodically based on the periodic interval specified, e.g., every 30 minutes |

You may enable one or more of these options to suit your preferences.

SAP Field Service Management Smartforms integration

Smartforms† provide a script for service execution, ensuring that technicians have the right script for the right scenario. A solution from SAP Field Service Management, Smartforms are managed in the Smartforms and Feedback app.

This integration allows the mobile client to download, modify, and upload Smartforms. These can be dynamic, multi-step forms used to capture safety data, inspections results, notes and much more.

All of us value consistency in service; a service script for technicians will promote efficiency and consistency.

Goods movement for production orders

Production orders use inbound and outbound procedures, by issuing components (raw materials) for the order production process, and then receiving those finished items into stock.

The production order screen includes tabs for the components, items, and the related material documents. The inventory clerk can easily see the details of each and initiate issuing and receiving right from the list.

Reversal of goods movement

The inventory clerk persona now supports reversal movement types 102 and 122.

The goods receipt reversal movement (102) is used to remedy an incorrect posting, perhaps the materials were received against the wrong order and it needs to be corrected. The return to vendor movement (122) is used, for example, when materials arrive damaged and must be returned to the vendor.

Consolidated completion screens

A great user experience improvement, completion screens are now consolidated into one screen. Previously, the user would see a series of windows for time confirmation, notes, signature, etc.

Aggregated items on map

It is common for multiple objects to have the same location, selecting them on a map can be difficult. It is now much easier to select collocated and overlapping objects on the map.

Tapping on a group of pins, will display a list of all the objects in the group. You may then select one from the list, to view more details.

Additional features

Enable Long Text Templates

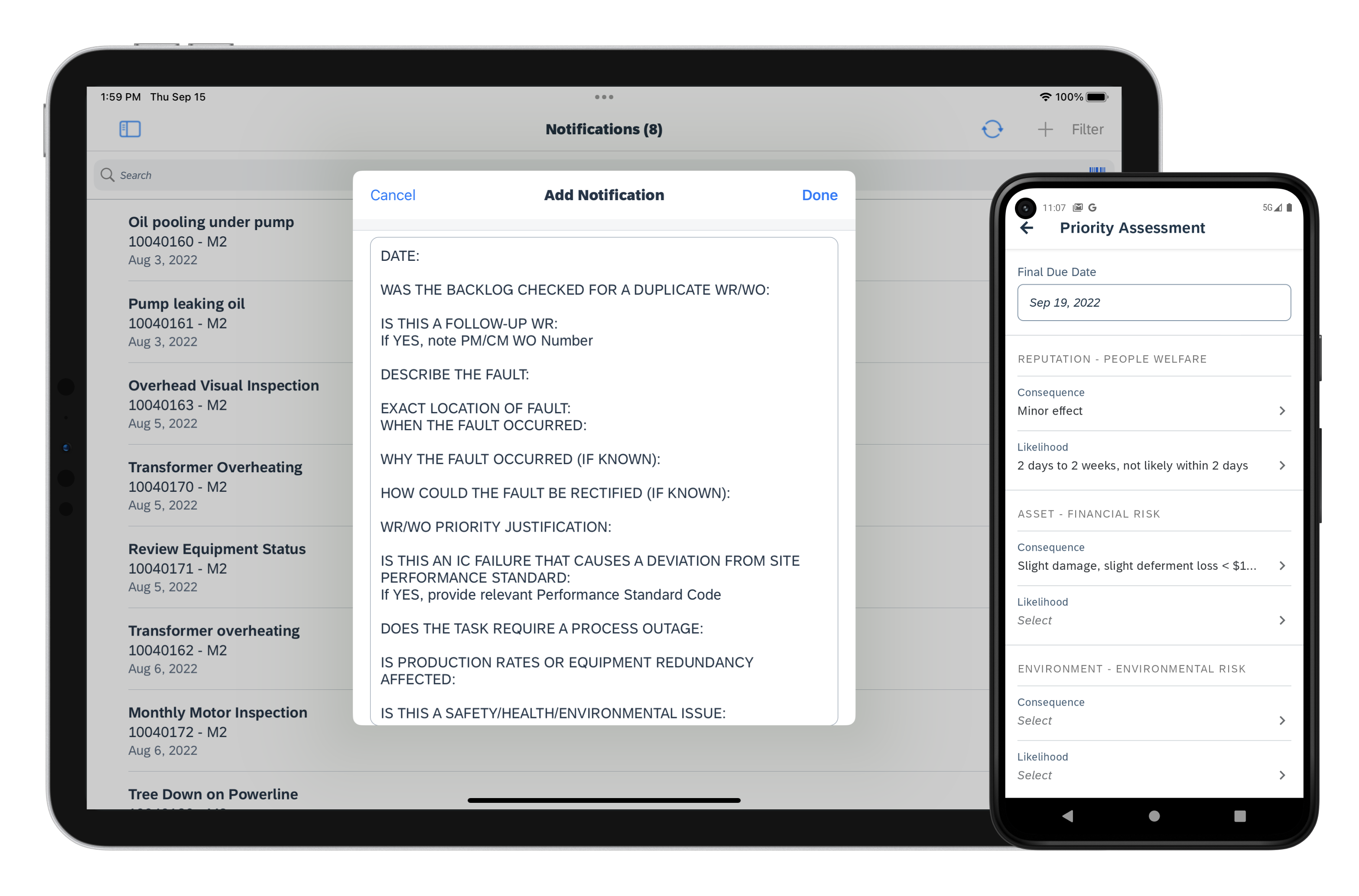

Long text templates are managed in the backend and serve as an outline to collect notes. For example, the template may instruct the user to “Please give the details of damaged part:”.

Technicians may access a template when entering notification details.

Include Event Prioritization*‡

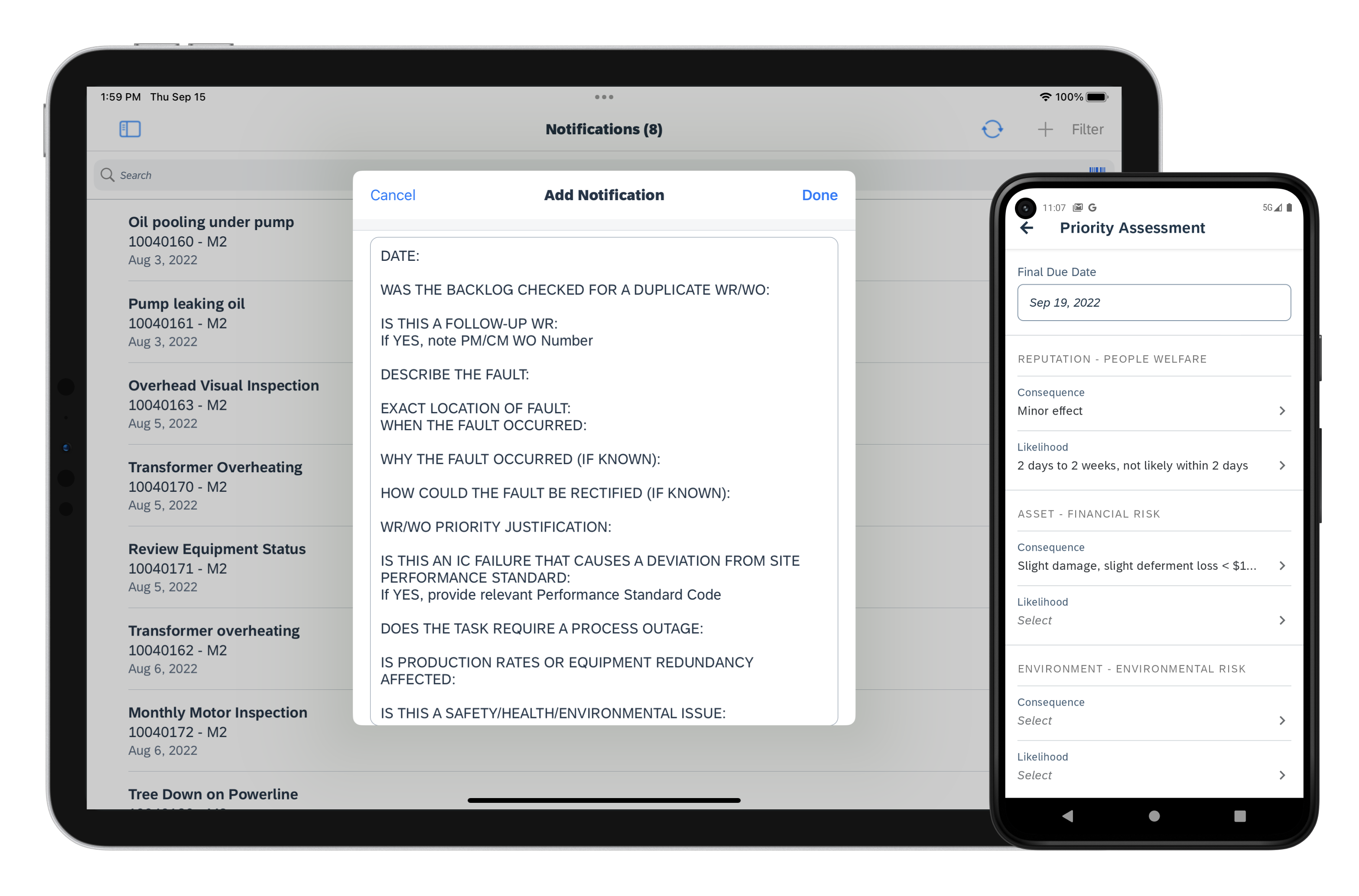

As we saw above, when reporting a malfunction it is important to gather good details to understand the issue. Event prioritization is a tool the technician may use to assess the priority of the notification. The feature allows you to select consequences and likelihoods in case of the failure of an equipment.

For example, a maintenance technicians observes an oil leak and wants to report this as a malfunction. The event prioritization feature suggests a very high priority because the equipment is critical to plant operations, and if it is not repaired within two weeks, it could damage the asset.

Filter parts by “Needed for Today”

When working with vehicle stock, it’s nice to see the parts that I will need for today’s orders. We added a “Needed for Today” filter to the Vehicle Stock Lookup list to give technicians another tool to find what they need easily.

Show system and user statuses*

Order, notification, and operation detail screens show system and user statuses; technicians see additional context on the state of the item

Show planned duration and number of technicians*

The operation details now include the number of techs assigned along with the planned duration, including the time per technician. It is common to capture a reason for time variance against the planned value so it helps the technician to know the planned duration for that operation.

To quote the customer request, this feature will "help the technician to plan the tasks and also as a reference in the time entries."

Display Technical Object ID*

Our list views now show the Technical Identification number, as this is often used as the primary ID by technicians when looking up equipment. The value is available via searching and scan as well. and is displayed in the header on the object page.

Display master PRT long text

A small but useful feature, a technician may now view long text for Production Resource/Tool (PRT) items. The text is shown as a note on the PRT equipment page.

Language support

Adds Vietnamese; 29 languages supported.

Release available now

The application is publicly available and includes an offline demo mode for viewing and testing the extensive functionality with maintenance technician, field service technician and inventory clerk personas included.

The application metadata is now available on the SAP Support Portal Software Center and the mobile client may be downloaded from the Apple App Store and Google Play Store.

* SAP Customer Influence request

† SAP Field Service Management is licensed separately; Smartforms is not included with SAP Service and Asset Manager.

‡ Only available with S/4HANA

Labels:

9 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

152 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

206 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

87

Related Content

- SAP S/4HANA Cloud ABAP开发案例之八:物料临期管理App in Enterprise Resource Planning Blogs by SAP

- Building Low Code Extensions with Key User Extensibility in SAP S/4HANA and SAP Build in Enterprise Resource Planning Blogs by SAP

- How to manage two credit limits for one customer in same sales area ? in Enterprise Resource Planning Q&A

- SAP Preferred Success: A Day in a Life in Product Change Management with Change Records in Enterprise Resource Planning Blogs by SAP

- Delegate Idoc Approval ( Absence of approver & other manager Approval in GROW ) in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 7 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |