- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Manufacturing in SAP S/4HANA Cloud 2208

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-06-2022

4:15 PM

This blog provides an overview of innovations in SAP S/4HANA Cloud 2208 for Manufacturing.

The SAP S/4HANA Cloud Manufacturing & Supply Chain blog series collects the links to the release blogs for Manufacturing and Supply Chain. The newest Supply Chain innovations are described in the separate blog post Supply Chain in SAP S/4HANA Cloud 2208.

First, this blog post starts with the table of contents for ease of reference and allows you to navigate directly to the topic you are interested in by clicking on a specific entry:

Check out my video highlighting SAP Quality Issue Resolution:

Video 1: Highlight for Manufacturing in the 2208 release: SAP Quality Issue Resolution

The Intelligent Handover in SAP Enterprise Product Development (EPD) enables production engineers to transform and restructure engineering bills of material (EBOMs) to manufacturing bills of material (MBOMs).

Figure 1: EPD Intelligent Handover of EBOMs to MBOMs - Process Overview

Once the EBOM has been handed over to a MBOM and the design engineer releases another change to the EBOM, the product engineer can also handover the BOM change to the corresponding MBOM.

Watch the next video which explains the steps of the handover process and shows in the system how to handover a BOM change.

Video 2: SAP Enterprise Product Development (EPD) - Intelligent Handover of EBOMs to MBOMs

(back to top)

In the area of Engineering Change Management, Impact Analysis for Change Record helps you to identify the objects affected by an engineering change and thereby, evaluate the potential impact of the change. Using this feature, you can perform impact analysis on a change item and identify the impacted objects from the color-coded impact chart.

Watch the next video where my colleague Markus Oertelt sets up an impact analysis scenario using the Manage Impact Analysis Models app, performs an impact analysis for a change record, and in addition explains the configuration.

Video 3: Engineering Change Management - Impact Analysis for Change Record

(back to top)

The new SAP Fiori app Process Production Versions is the one-stop solution for production versions that offers the following capabilities:

In the next video Markus shows you the new app in the system:

Video 4: New SAP Fiori app 'Process Production Versions'

As the icing on the cake, the app offers a network graph that visualizes the relationships of linked production versions.

Figure 2: New SAP Fiori app 'Process Production Versions' - Graph of Linked Production Versions

Figure 3: 'Manage Your Solution' app - New configuration step 'Define Rules for Production Version Proposals'

(back to top)

The Capacity Scheduling Table app is the "heart" of capacity planning in SAP S/4HANA Cloud. So it's obvious that we constantly extend this app. With 2008, the following new features are available within the app:

In the next video Markus shows the new features in the system.

Video 5: 'Capacity Scheduling Table' app - App Extensibility, view product configuration, enhanced Status Overview and Issues information

(back to top)

With the Manage Planned Orders app, you can view the Long Text in the List Page entered during the creation of Planned Order.

While converting the Planned Order to a Production order or a Process Order, the long text will be copied to the newly created orders.

Figure 4: 'Manage Planned Orders' app - Long Text

(back to top)

With the past release, we introduced the new selection guide to find the right planning strategy group and offered 10 additional planning strategies and planning strategy groups (see my 2202 blog and Markus' blog post Manufacturing in SAP S/4HANA Cloud – Planning Strategies).

With 2208, the new planning strategy Sales from Project Stock Without Planning (E2) is available for covering engineer-to order processes. This planning strategy is used when sales is based on the project stock, that is when each product is specifically produced for a WBS element from your project management, for example, SAP Enterprise Portfolio and Project Management (EPPM). You use the project structure for collecting costs and to drive production planning based on the associated sales order items.

Figure 5: 'Manage Your Solution' app - Configuration step 'Display Planning Strategies' with new strategy 'E2' for Engineer-to-order production

(back to top)

The storage location determination has been enhanced to also allow for determination via production versions of phantom assemblies.

When working with phantom assemblies goods issues for components of the phantom assembly can be posted from the default production supply area (PSA) derived from the phantom assembly's production version.

For this purpose, the configuration step Define MRP Groups offers now the new strategies 5, 6 and 7 for storage location determination as shown in the next figure.

Figure 6: 'Manage Your Solution' app - Configuration step 'Define MRP Groups'

(back to top)

The time-phased planning procedure has been optimized allowing for an improved system performance when planning a high volume of materials using planning with a planning calendar.

If a vendor always delivers a material on a particular day of the week, it makes sense to plan this material according to the same cycle, in which it is delivered.

Materials that are planned using the time-phased planning technique are provided with an MRP date in the planning file. This date is set when creating a material master and is re-set after each planning run. It represents the date on which the material is to be planned again and is calculated on the basis of the planning cycle entered in the material master.

Time-phased planning can be executed using consumption-based planning or MRP.

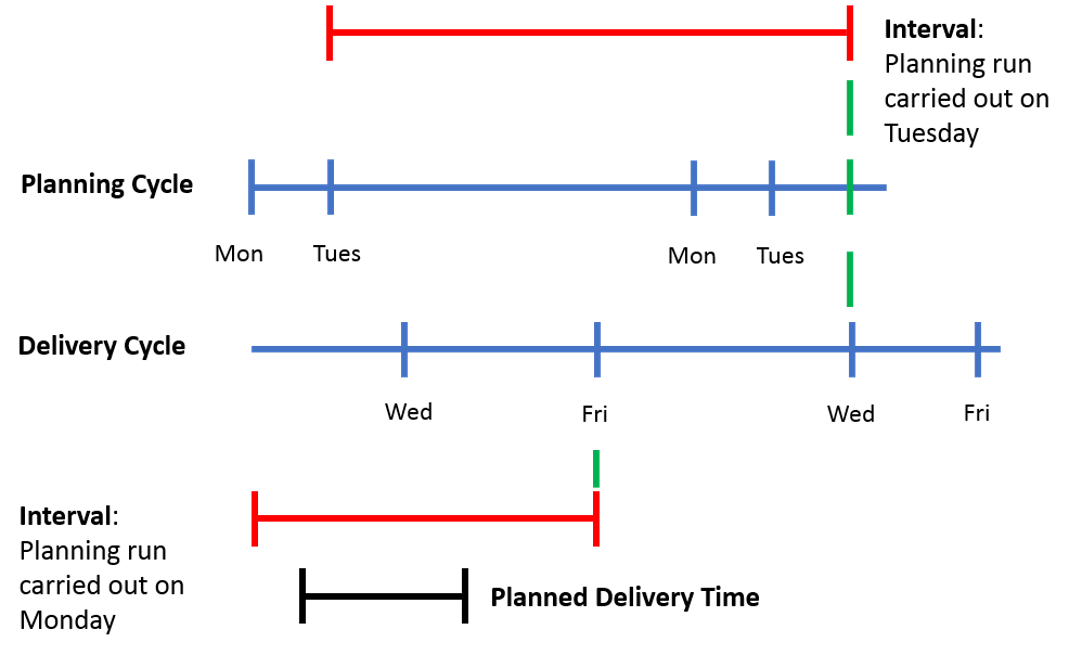

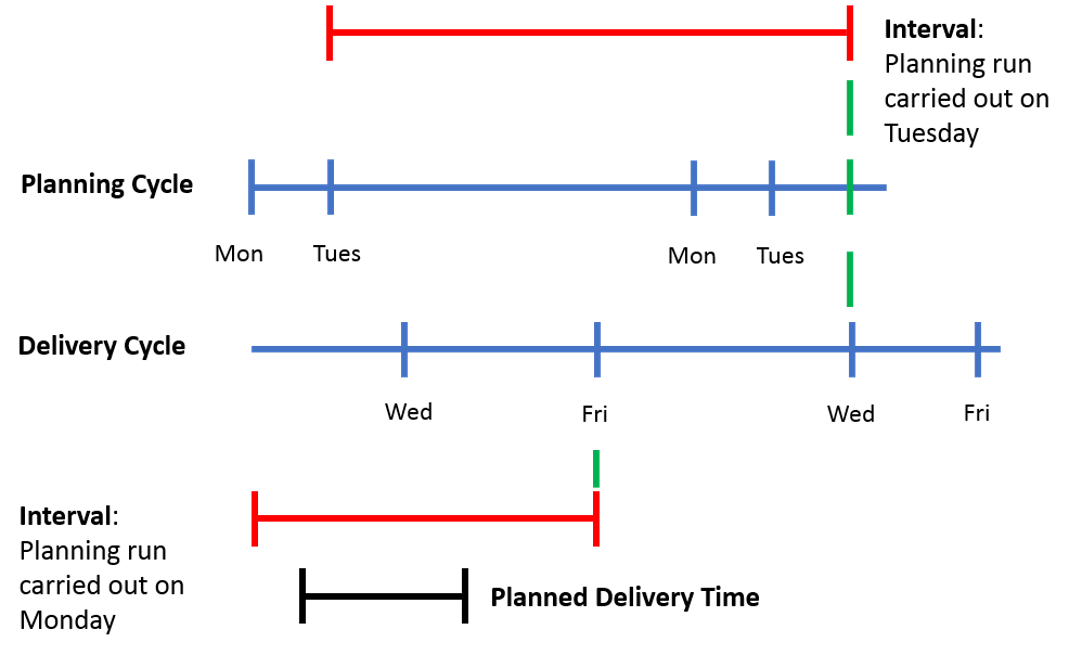

The next figure shows for instance a time-phased planning scenario with regular deliveries on Wednesday and Friday and planning runs carried out on Monday and Tuesday.

The MRP run on Monday (see red time period below) plans the delivery for Friday by considering the planned delivery time (see black timeline below). The match of Friday's delivery with the result of Monday's MRP run is illustrated with the green bar.

The MRP run on Tuesday with the long planning period until Wednesday next week (see red time period above) makes sure that the delivery on Wednesday can be fulfilled illustrated by the green bar that matches Wednesday next week.

Figure 7: MRP time-phased planning procedure - Scenario with regular deliveries on Wednesday and Friday and planning runs carried out on Monday and Tuesday

Time-phased planning is usually used in the retail sector and is therefore an important requirement of the retail industry.

(back to top)

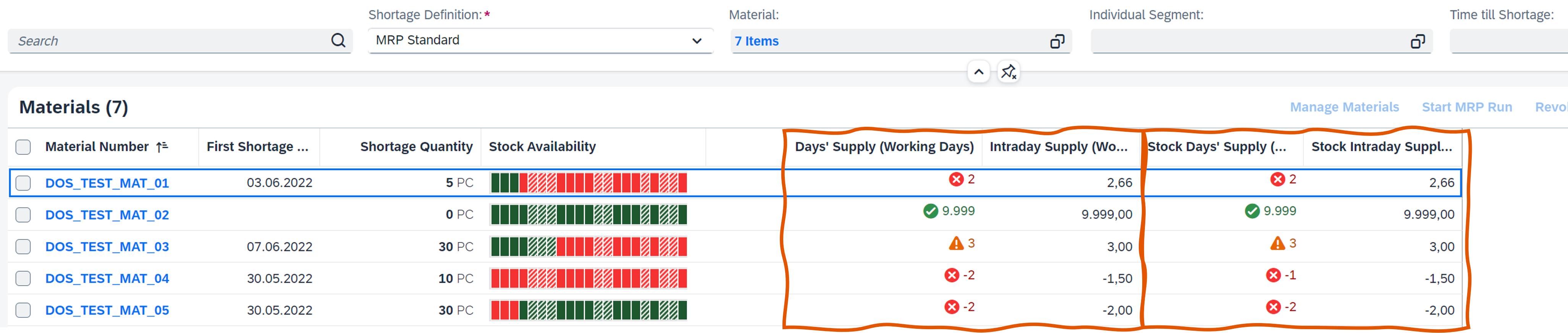

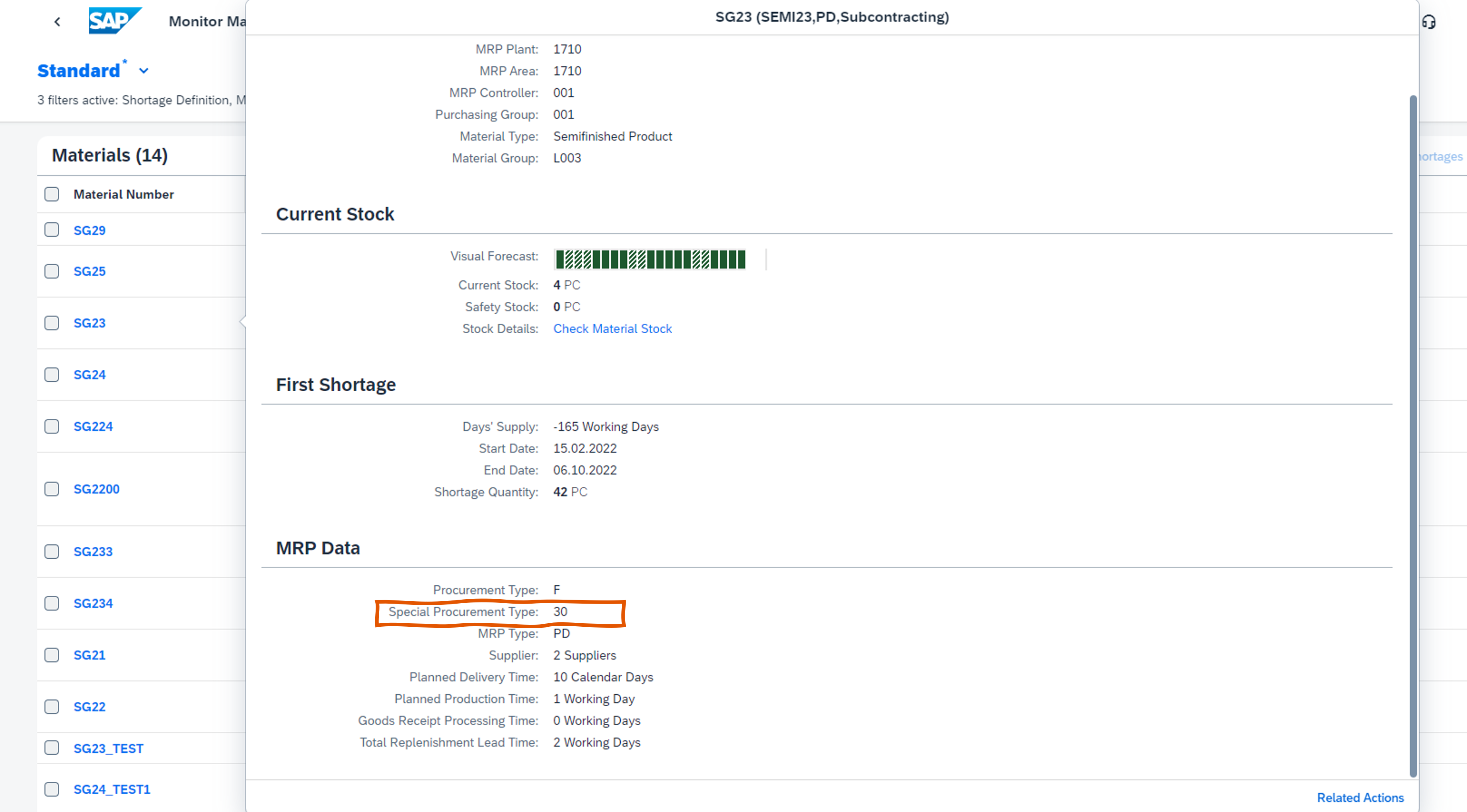

The Monitor Material Coverage - Net Segments and Monitor Material Coverage - Net and Individual Segments apps were enhanced with additional columns and filters to support you with identifying and handling MRP issues. In addition, special procurement types are now displayed in the material list and quick view.

Figure 8: 'Monitor Material Coverage' app - Past Due Elements

Figure 9: 'Monitor Material Coverage' app - Stock Day's Supply and Stock Intraday Supply

Figure 10: 'Monitor Material Coverage' app - 'Special Procurement Type' column on material list

Figure 11: 'Monitor Material Coverage' app - 'Special Procurement Type' field on object page

With this enhancements we provide the production planner using SAP Fiori apps with functionally they are get used to based on MRP lists (MD06).

The What's New document describes these enhancements in detail (see chapter 13.3.6.5.).

Additional enhancements were made to enable working with time-dependent safety stock and reorder points in the Monitor Material Coverage apps (see next chapter).

(back to top)

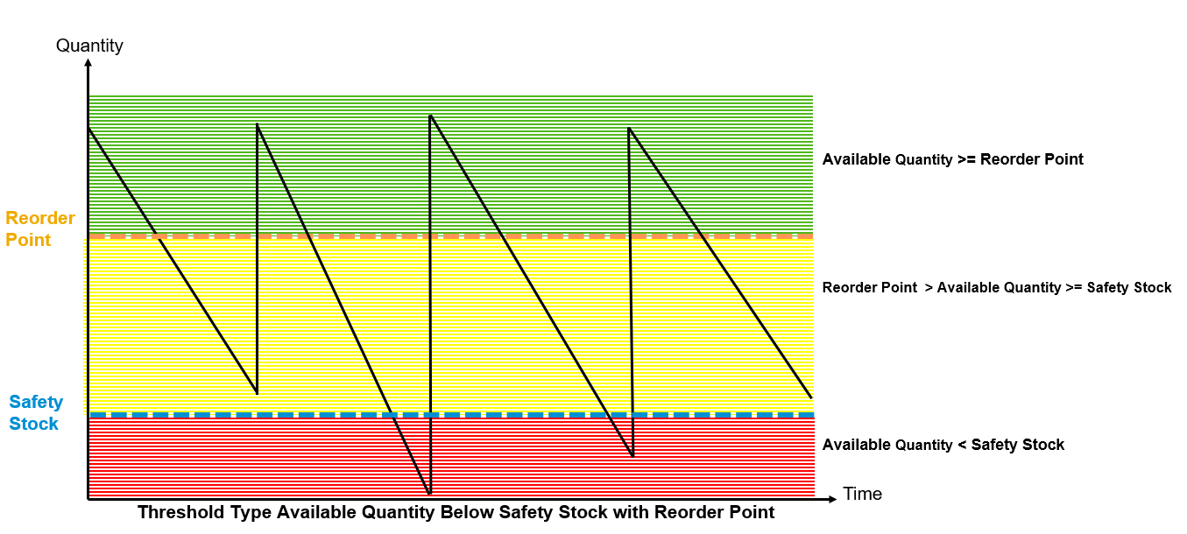

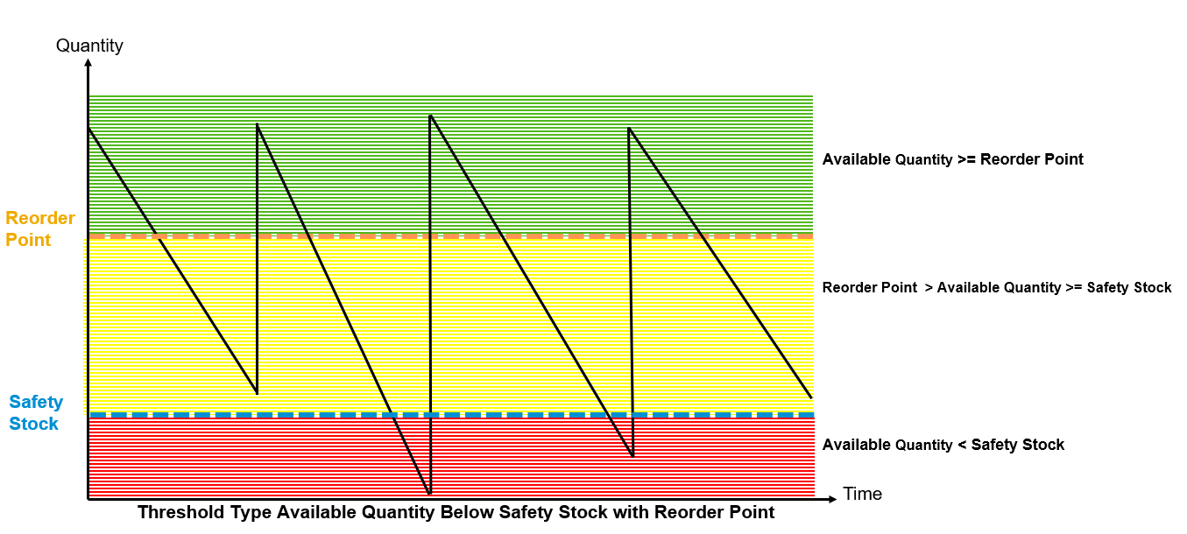

The new threshold type Available Quantity Below Safety Stock with Reorder Point is now available for shortage definitions that can be used in the Monitor Material Coverage - Net Segments and Monitor Material Coverage - Net and Individual Segments apps. You can use material shortage definitions with this threshold type to determine how material shortages are displayed. If you select a

shortage definition with the new threshold type assigned, the stock availability chart reflects stock levels as follows:

Figure 12: Threshold type 'Available Quantity Below Safety Stock with Reorder Point' and color code of stock level

The next figure shows the configuration activity Define Material Shortage Profiles with the new option to select the threshold type Available Quantity Below Safety Stock with Reorder Point.

Figure 13: 'Manage Your Solution' app - Configuration activity 'Define Material Shortage Profiles' - new threshold type 'Available Quantity Below Safety Stock with Reorder Point'

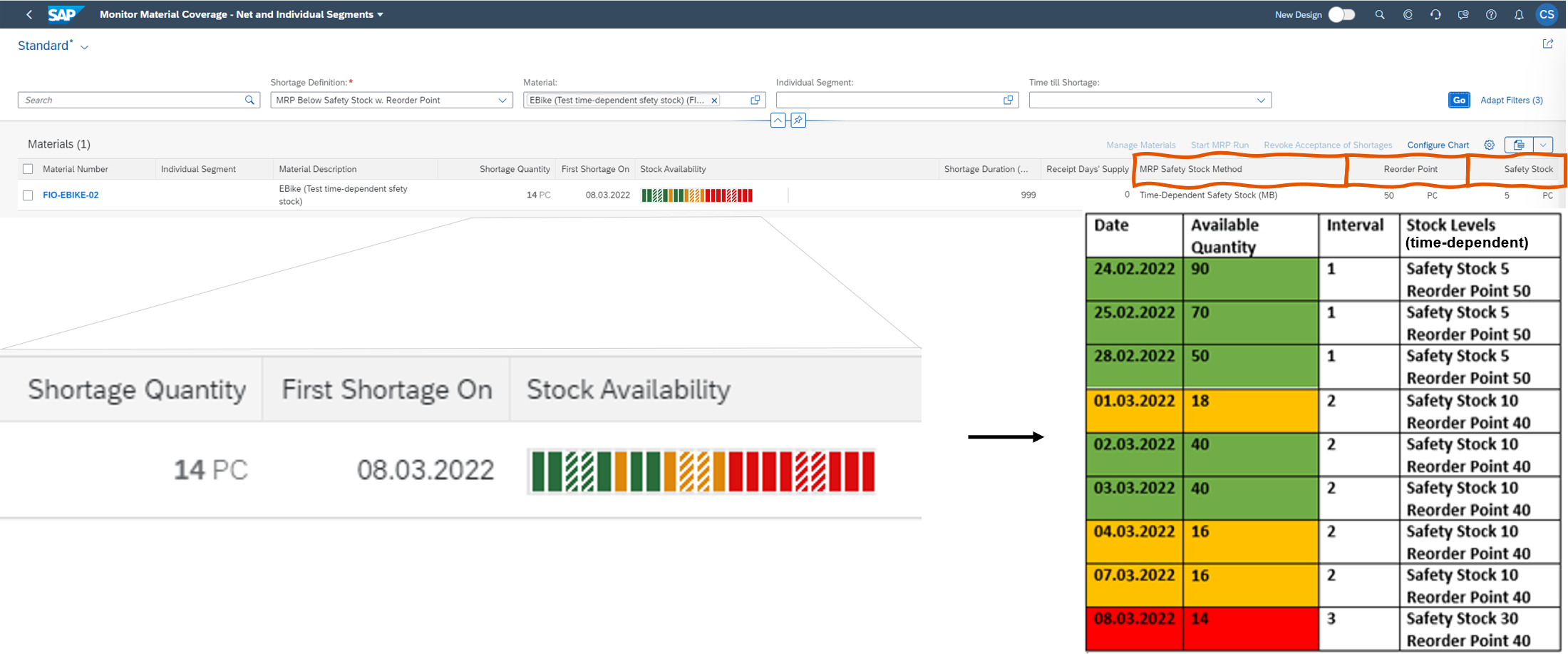

In addition, the new columns Safety Stock, Reorder Point, and MRP Safety Stock Method were added to the material overview table and the stock availability chart was adapted to reflect time-dependent safety stock levels defined in the Maintain Time-Dependent Stock Levels app.

(back to top)

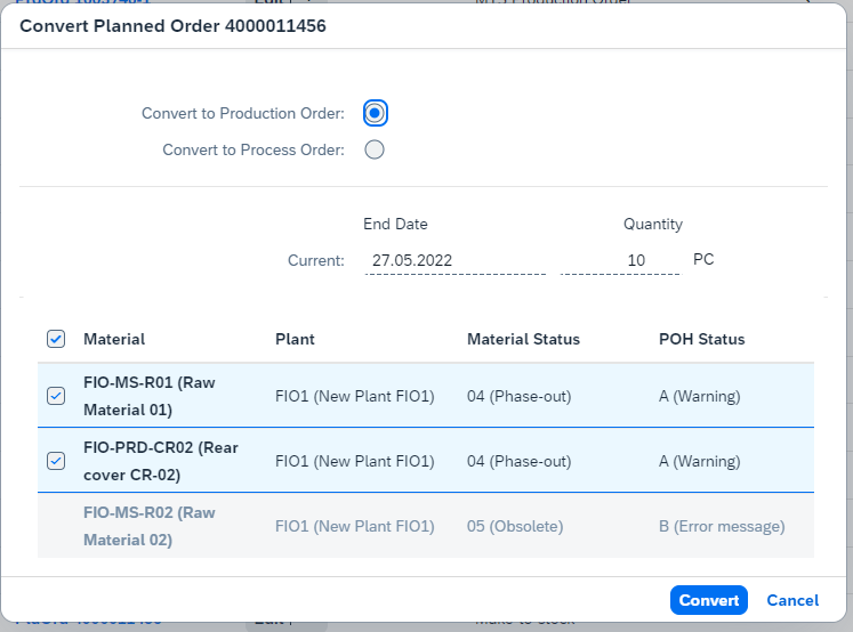

In the Manage Material Coverage app, you can convert planned orders into production orders or process orders.

If warnings are issued for the components of a material based on their material status, you can use this feature to select whether you want to include these components in an order or not.

You can also check for material components that are blocked from conversion due to their material status.

Figure 15: 'Manage Material Coverage' app - Convert Planned Order

(back to top)

With 2208, we offer the first Business-Add In (BAdI) for Material Requirements Planning. Technically this is an AMDP (ABAP Managed Database Procedures) BAdI.

The Business-Add In (BAdI) PPH_SUPPLY_DEMAND_LIST has been made available for developer extensibility. It is used to remove or change standard MRP elements or add custom MRP elements to the supply and demand list in order to adapt MRP to your company’s needs. The changes are considered by the MRP run and they are displayed in the MRP apps.

In the following demo video I explain the example implementation for adding MRP elements, in this case to reduce stock for expiring products and show the impact of the BAdI implementation on a MRP run using a simple example.

Video 6: Business Add-In 'Modification of Supply and Demand List'

Note: The AMDP BAdI is only available for customers with a 3-System Landscape (3SL). The 3SL architecture introduces a development tenant into the landscape and will offer our customers and partners enhanced extensibility via in-app development with the SAP S/4HANA Cloud, ABAP Environment, (aka embedded steampunk). For further information read the blog post Embedded Steampunk – Some more details for ABAP developers.

(back to top)

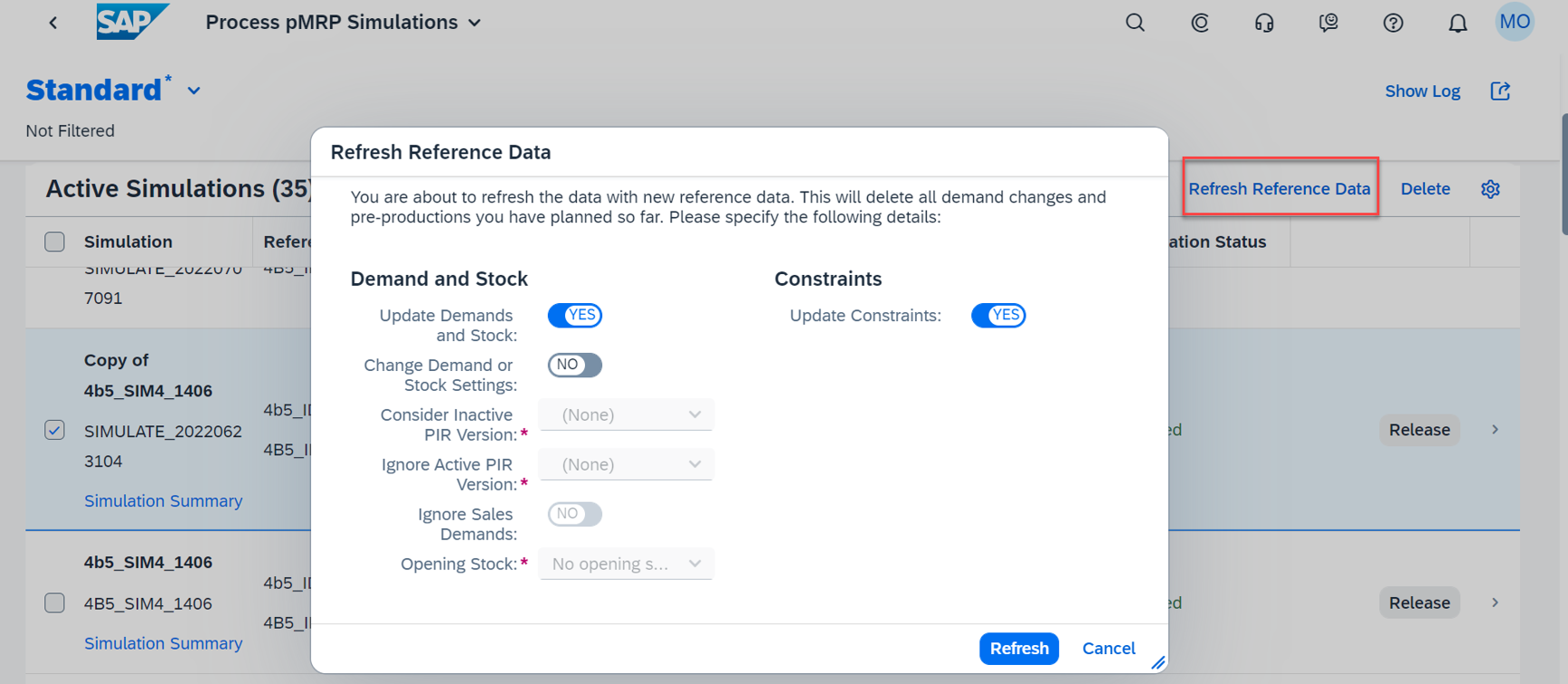

In the Process pMRP Simulations app you can update specific stock, demand and constraint quantities and use the updated data for your simulations based on the same reference without the need to schedule a new simulation creation from scratch.

Figure 16: Process pMRP Simulations app - Refresh Reference Data

(back to top)

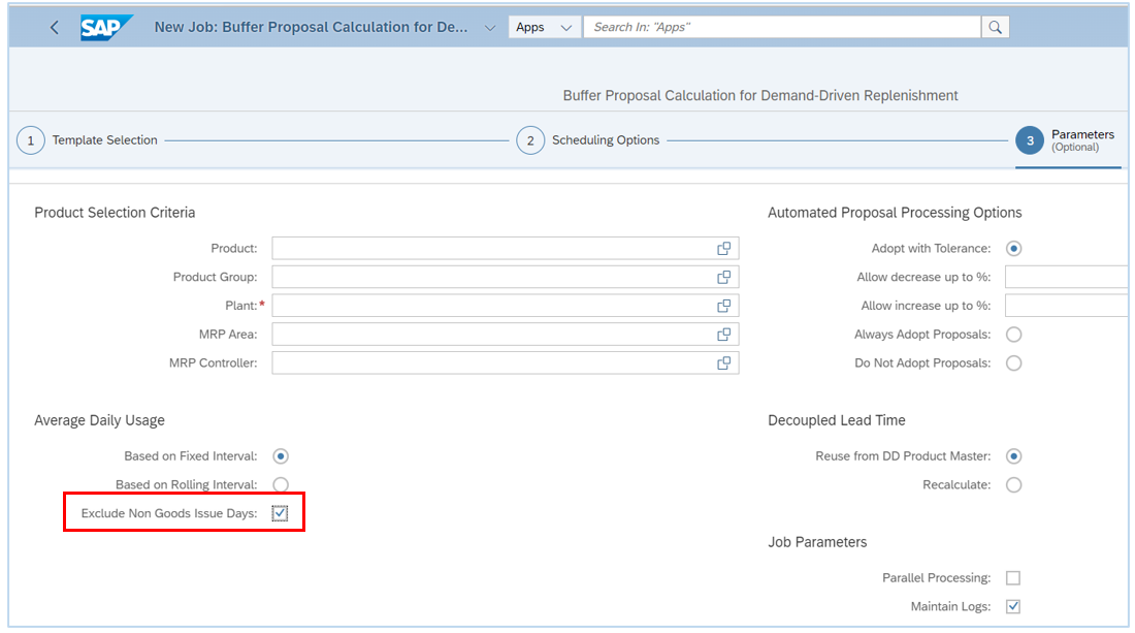

A year ago, I last presented a major improvement in the area of Demand Driven Replenishment (DDR) for support of repetitive manufacturing (see my 2108 blog). Following many customer requests for more flexibility in calculating important parameters for buffer positioning (XYZ classification) and buffer sizing (ADU and variability factors), we now deliver the next very useful enhancement for DDR:

The apps Schedule Product Classification (DD) and Schedule Buffer Proposal Calculation enable you to exclude the days when no goods issues took place for the material in the related background jobs to schedule product classification and schedule buffer proposal calculation. The next two screenshots show the new flag Exclude Non Goods Issue Days in both apps.

Figure 17: 'Schedule Product Classification (DD)' app - Exclude Non Goods Issue Days

Figure 18: 'Schedule Buffer Proposal Calculation' app - Exclude Non Goods Issue Days

(back to top)

With the past release, we enabled business transaction control for production orders (see my 2202 blog).

In addition, you can now control which business transactions are allowed for a process order or an order operation depending on other business transactions that are executed.

This function is available in all apps that make changes to process orders, for example,

The following configuration steps are relevant for the Business Transaction Control:

(back to top)

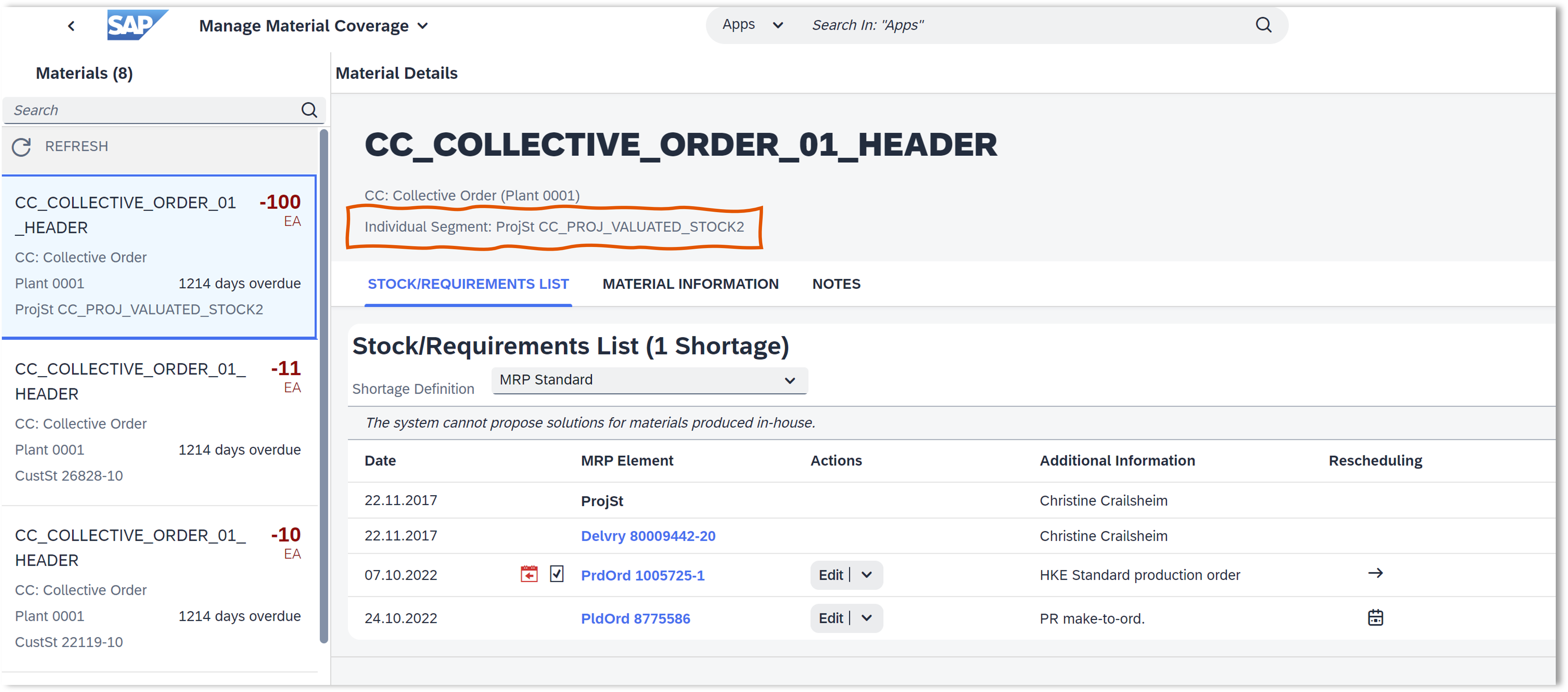

You can use the Create Production Order with Project app to create a production order for project stock within engineer-to-order production.

Figure 19: 'Create Production Order with Project' app

The Manage Material Coverage app displays in the Individual Segment field that this is a production order for project stock within engineer-to-order production as shown in next screenshot. Most often users navigate from the Monitor Material Coverage app to the Manage Material Coverage app, but you can also call the Manage Material Coverage app directly from Fiori launchpad tile Check Material Coverage.

Figure 20: 'Manage Material Coverage' app - Individual Segment: Project Stock

(back to top)

In the Manage Production Orders app the issue types are enhanced with Failed Material Movements in the filter, worklist and issue summary in the detailed page as shown in the figure below.

Also the navigation to the Reprocess Failed Material Movements application is supported.

Figure 21: 'Manage Production Order' app - Issue Type 'Failed Material Movements'

Moreover, the production supervisor apps Manage Production Orders and Manage Production Operations enable you now to display and filter user-defined statuses for production orders and operations in the worklist. By using user-defined statuses, you can control which business transactions are enabled or disabled for a production order in a certain status.

Worklists and details page are enhanced with Related Apps button, navigates to order-specific apps as well as other order-related apps.

(back to top)

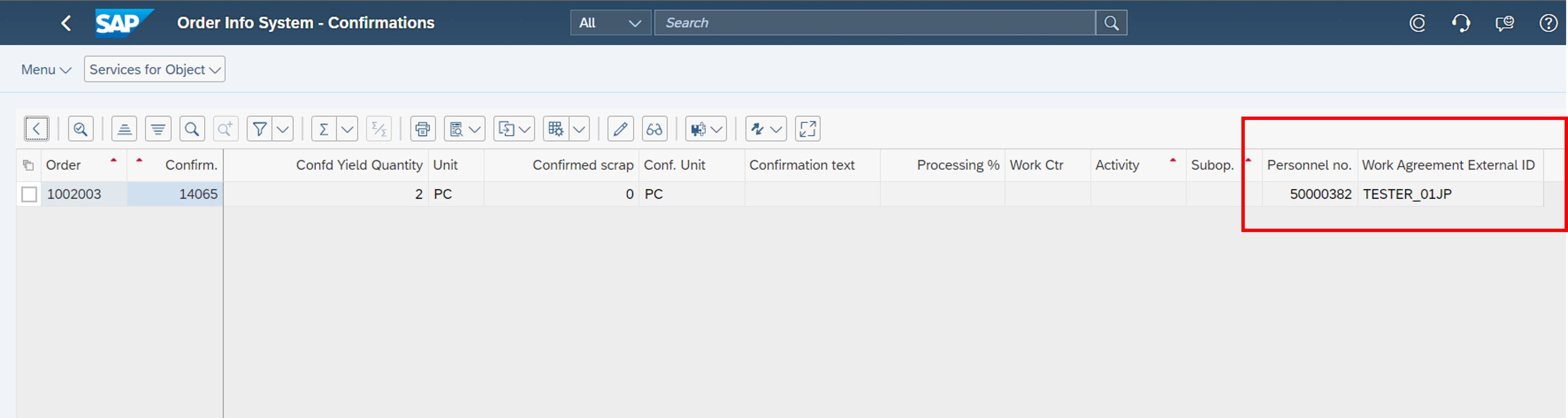

You can display external personnel numbers in the Confirmations list in both the Monitor Production / Planned Orders app and the Monitor Process / Planned Orders app.This is useful, for example, if you want to display the external personnel numbers of employees who have entered confirmations for certain production orders. On the output list, change the layout to include the column Work Agreement External ID.

Figure 22: Order Informations System - External personnel number

(back to top)

With the Confirm Production Operation app, a production operator can partially or completely confirm production operations. When you have entered the order and operation number for confirmation the system proposes data for quantities and activities by default. You can now configure that the system shall not propose those values automatically. To actively request them, you use the Get Proposals button. If you have overwritten the proposed values and want to reset them, you can also use the Get Proposals button.

Figure 23: 'Confirm Production Operation' app - new 'Get Proposals' button

(back to top)

SAP Quality Issue Resolution is an interactive platform to support you with solving and preventing quality issues. It is the successor of SAP Supplier Problem Solving (see my 2202 blog) and runs on BTP (SAP Business Technology Platform). SAP Quality Issue Resolution uses the 8D methodology for a team-oriented problem-solving approach.

Starting point of the 8D problem-solving process with SAP Quality Issue Resolution is the quality notification in SAP S/4HANA Cloud. From the action box in the notification, you can trigger creation of a new 8D. Information such as material number, defect details, and business partner are transferred from the quality notification to SAP Quality Issue Resolution.

With 2208 release, the integration between quality notification in S/4HANA Cloud and SAP Quality Issue Resolution is provided. The next figure illustrates the integration between SAP Quality Management in S/4HANA Cloud and SAP Quality Issue Resolution running on BTP.

You can request the 8D problem-solving for

Figure 24: Integration between quality notification in S/4HANA Cloud and SAP Quality Issue Resolution

The next video shows you the 8D problem-solving process in case of Complaint Against Supplier:

Video 7: SAP Quality Issue Resolution - 8D problem-solving process for Complaint Against Supplier

(back to top)

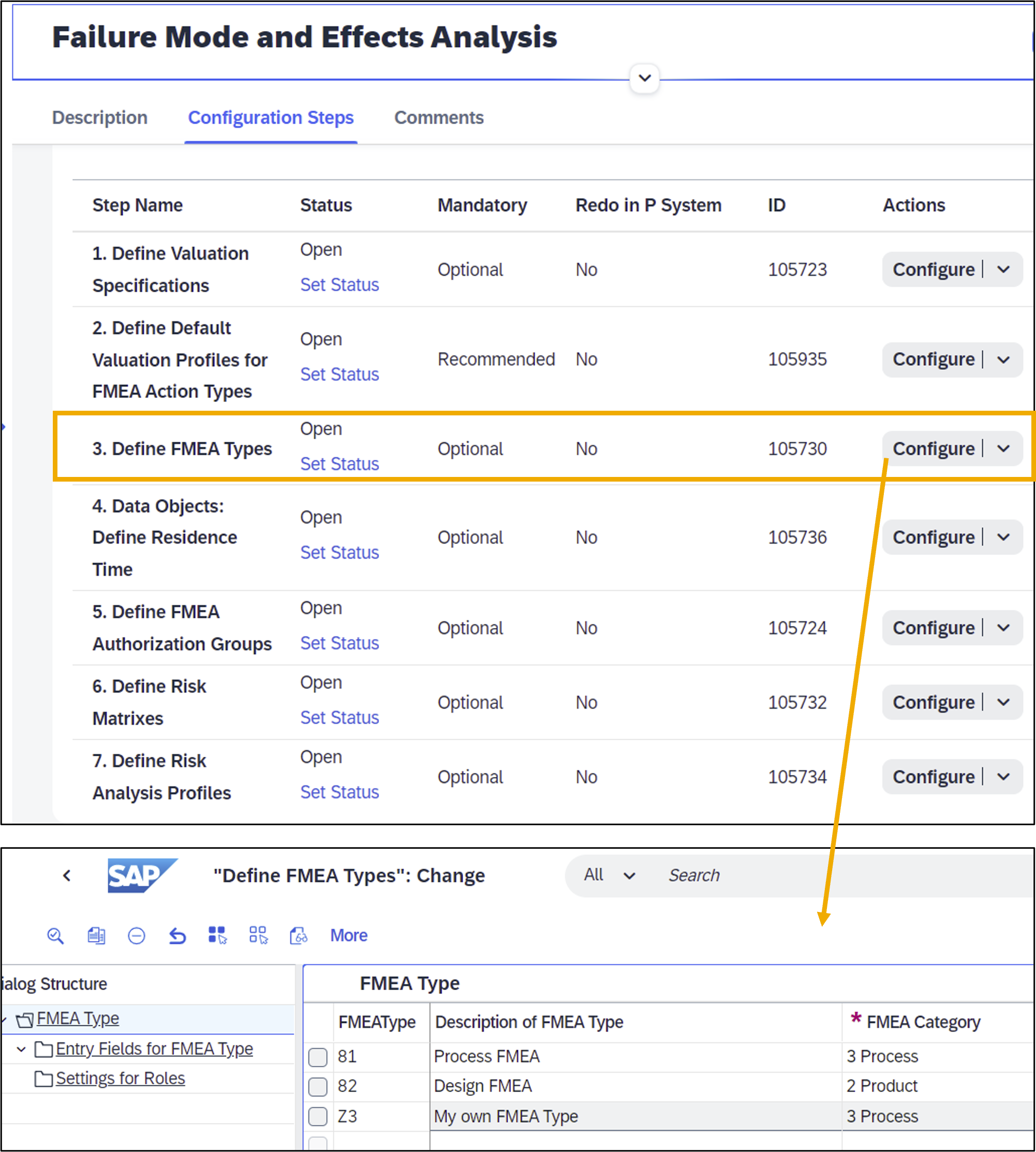

In my 2202 blog I highlighted the Failure mode and effects analysis (FMEA).

With 2208, we deliver the following FMEA enhancements:

The following figure shows the FMEA configuration steps that are available with the 2208 release. The figure highlights explicitly step 3 that allow you to define your own FMEA type.

Figure 25: 'Manage Your Solution' app - New FMEA configuration steps e.g. 'Define FMEA Types'

The following changes were made in the Manage FMEAs app:

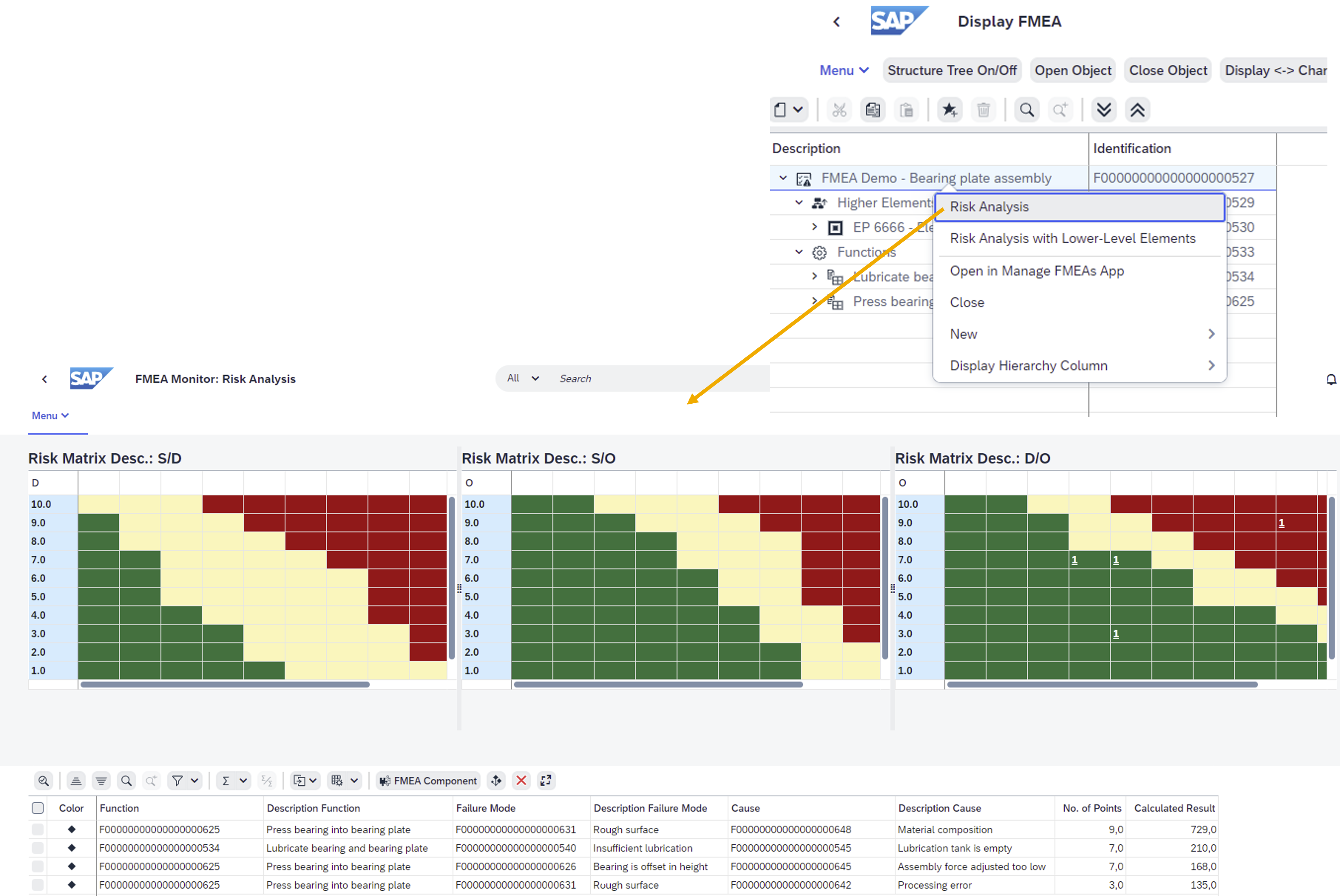

You can use this feature to run a risk analysis for the causes in an FMEA based on detection actions and preventive actions and the severity of failure modes, and represent the risk using risk matrixes. The risk analysis is based on the action priority method. You can start the risk analysis for one or more FMEAs from the FMEA monitor and from the FMEA cockpit.

Figure 29: 'FMEA Cockpit - Display FMEA' calls 'FMEA Monitor - Risk Analysis'

The following new configuration activities are relevant for risk matrixes:

(back to top)

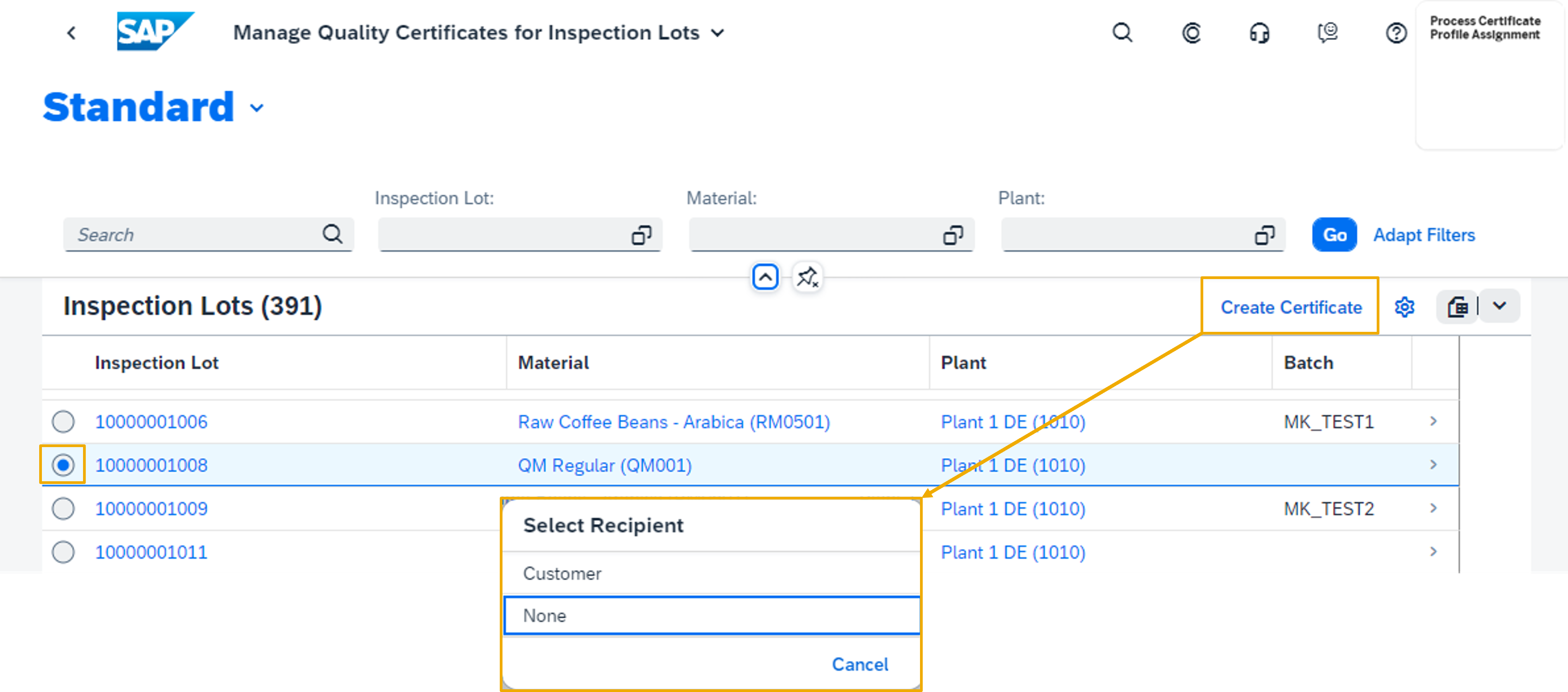

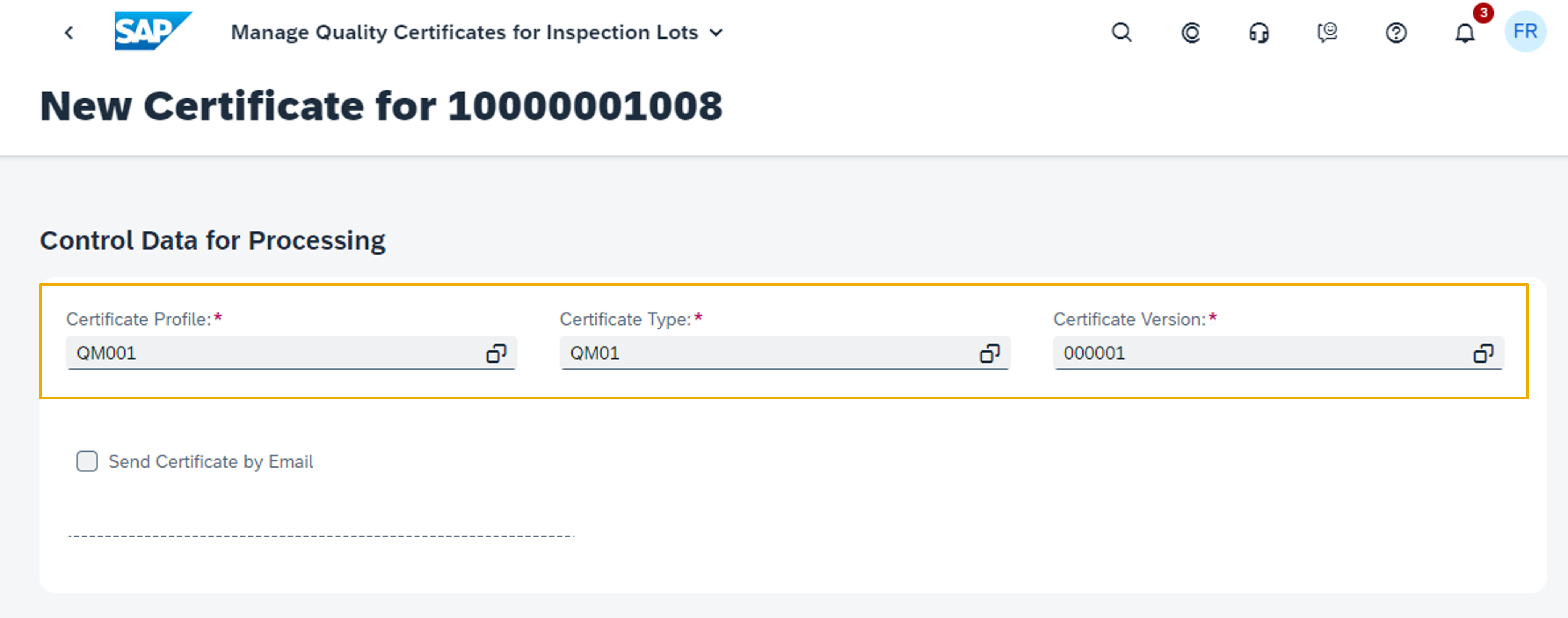

With 2202 Release, the apps “Manage Quality Certificates for Batches” and “Manage Quality Certificates for Inspection Lots” were enhanced with an automatic certificate profile determination. Based on the customer requirement not to be forced to maintain condition records for using these apps, a further enhancement is introduced with this release.

In case there are no matching entries available in the condition tables in app “Process Certificate Profile Assignment”, you can select the profile directly while creating the quality certificate in these apps.

Please find screenshots below illustrating this enhancement in app Manage Quality Certificates for Inspection Lots.

Figure 30: 'Manage Quality Certificates for Inspection Lots' app - Create Certificate

In case a condition record is determined the certificate profile data is automatically filled. You can change the entries manually if needed.

Figure 31: 'Manage Quality Certificates for Inspection Lots' app - Certificate profile data is automatically filled if condition record is determined

(back to top)

For Inspection Lot Status the status Created is now available as filter criteria. This helps to identify inspection lots which need attention before results recording can start.

Figure 32: 'Manage Inspection Lots' app - Filter for Created Inspection Lots

(back to top)

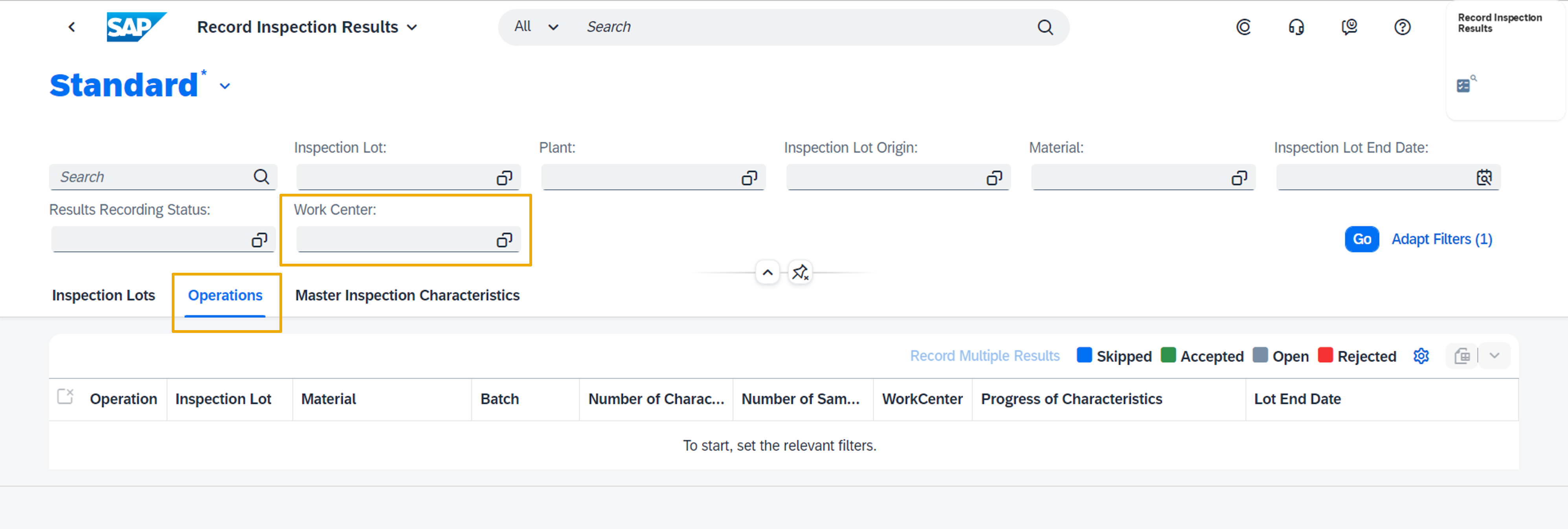

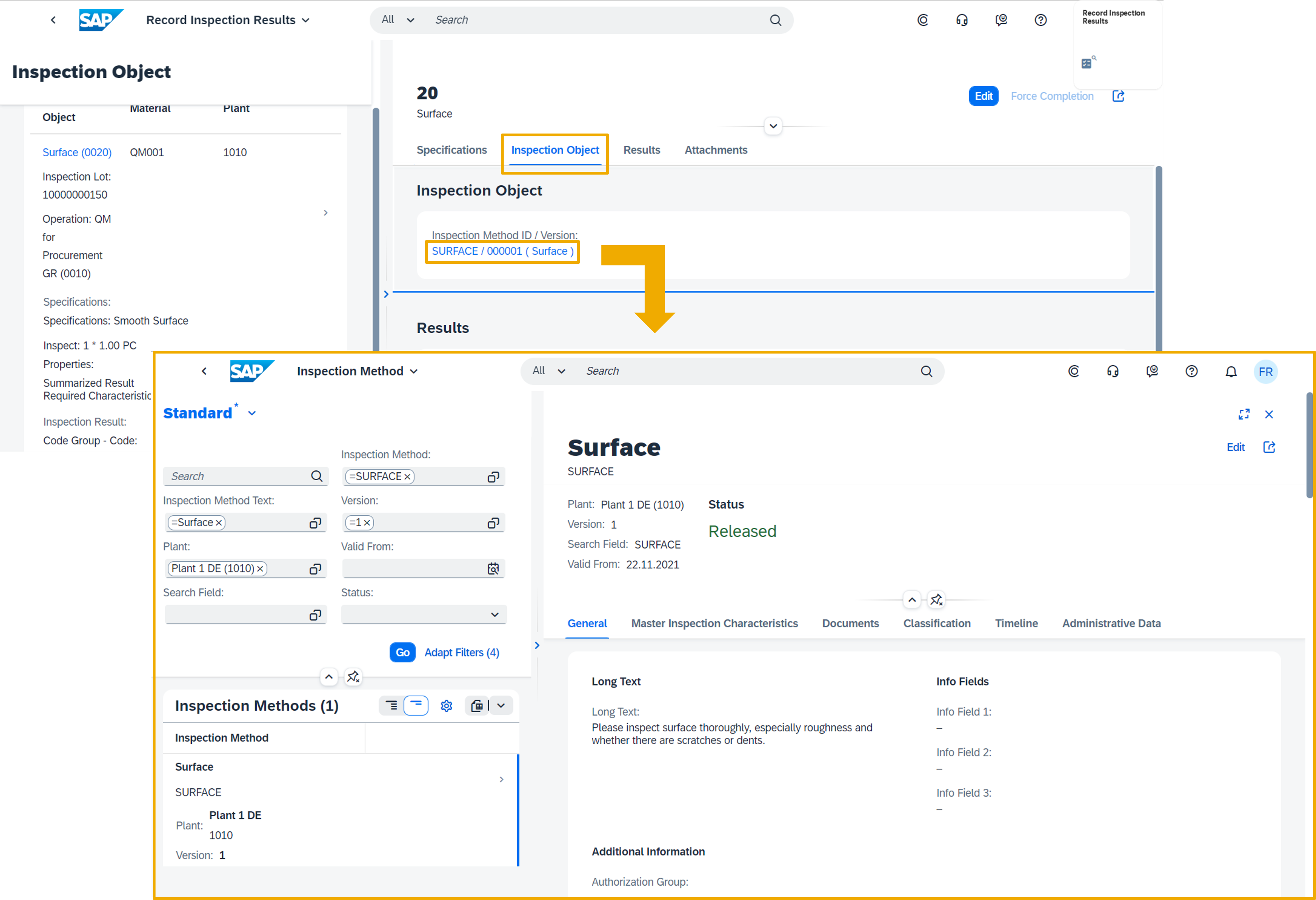

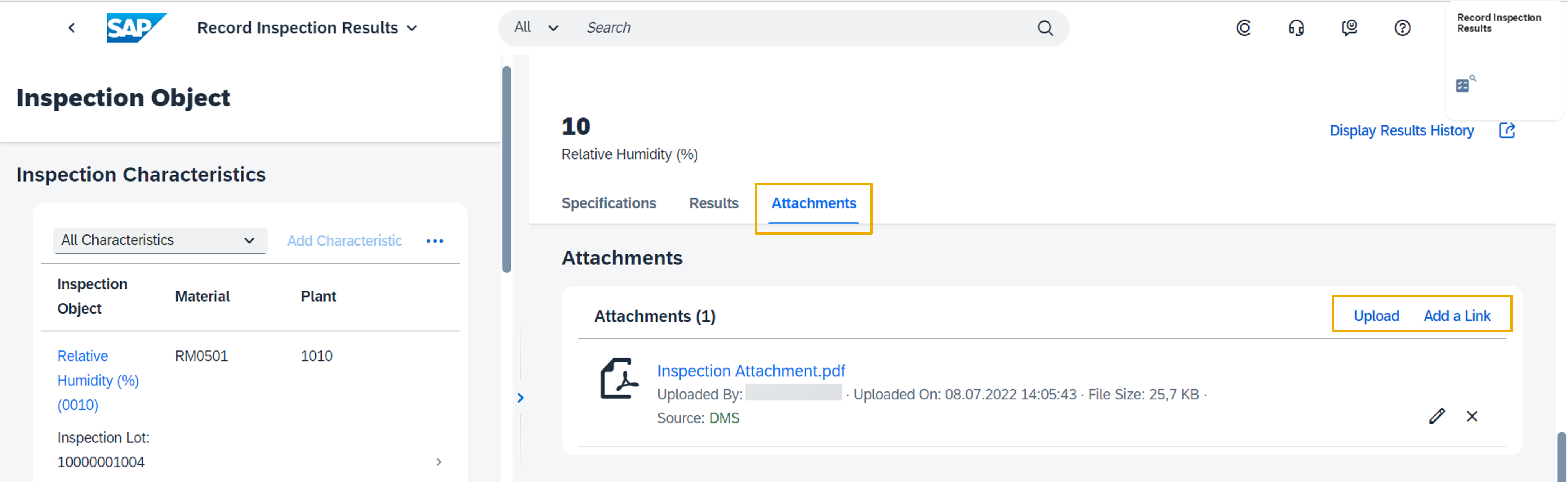

With the 2108 release, the new Record Inspection Results app was introduced as the successor of the Record Inspection Results (Deprecated) app (see my 2108 blog).

With the Record Inspection Results app, you can now:

(back to top)

With this feature, you can directly post synchronous goods receipts from other parts of SAP S/4HANA Cloud into Warehouse Management for goods procured externally or goods from in-house production. The system creates an inspection lot when a goods receipt is posted for a product that’s inspection-relevant, for example, in the Post Goods Movements app. This feature is also described in the blog post Supply Chain in SAP S/4HANA Cloud 2208.

Figure 39: Inspection lot creation for synchronous goods receipt postings

(back to top)

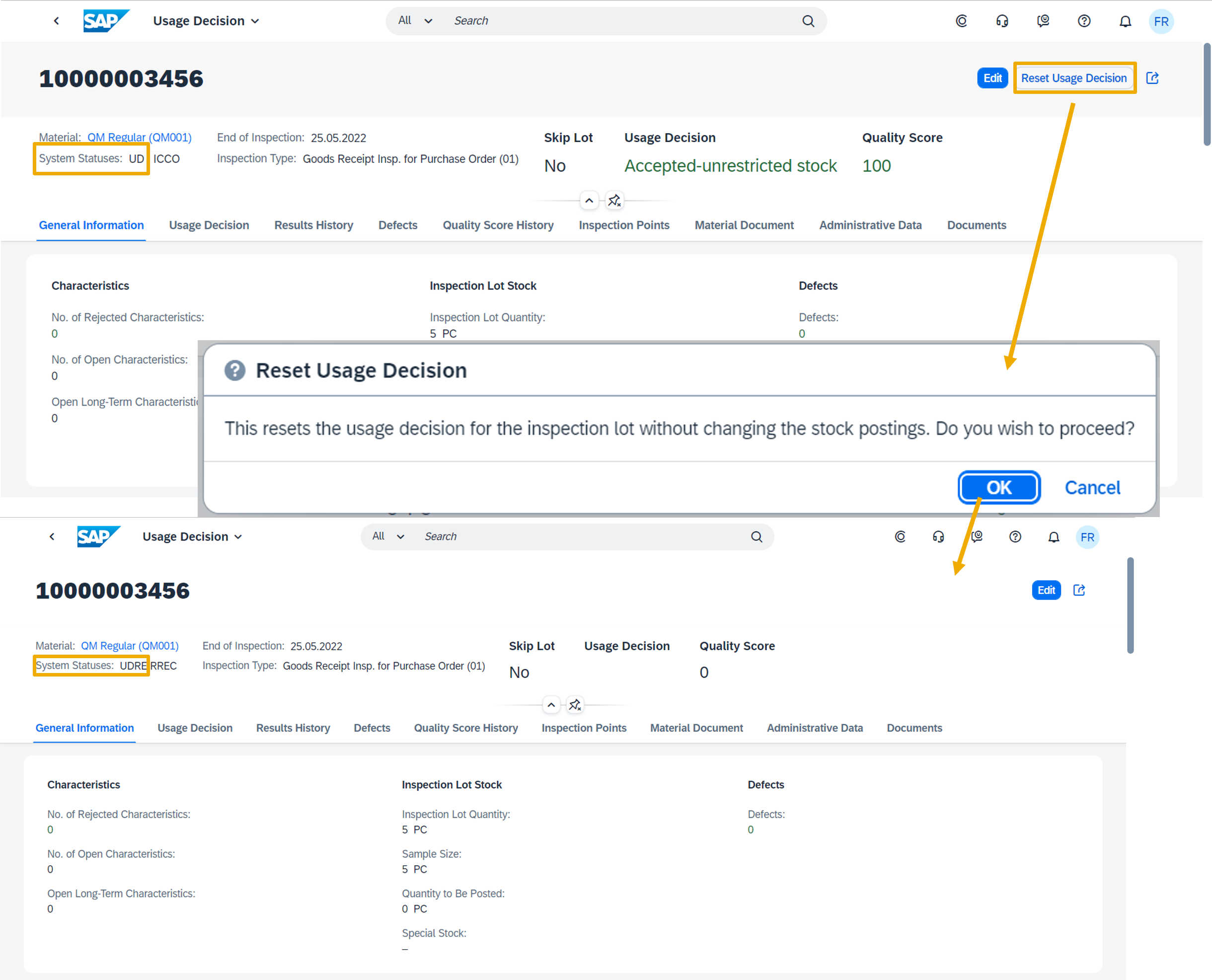

You probably know the possibility to change a usage decision for inspection lots in S/4HANA Cloud. But in some cases, changing the usage decision might not be sufficient and you want to delete the previously recorded usage decision. To meet this requirement a new Reset Usage Decision button is available now in Manage Usage Decision app.

Figure 40: 'Manage Usage Decision' app - Reset Usage Decision

To activate the Reset Usage Decision button, maintain configuration step 102456 Maintain Settings at Plant Level.

(back to top)

Thanks for reading this blog post. Stay tuned!

You will find a collection of my SAP S/4HANA Cloud release blogs here:

My colleague Markus Oertelt writes an interesting blog series about

Discrete Industries in SAP S/4HANA Cloud.

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn

The SAP S/4HANA Cloud Manufacturing & Supply Chain blog series collects the links to the release blogs for Manufacturing and Supply Chain. The newest Supply Chain innovations are described in the separate blog post Supply Chain in SAP S/4HANA Cloud 2208.

First, this blog post starts with the table of contents for ease of reference and allows you to navigate directly to the topic you are interested in by clicking on a specific entry:

Product Development

SAP Enterprise Product Development - Intelligent Handover (+ demo video)

Impact Analysis for Change Record (+ demo video)

Production Engineering

Process Production Versions (+ demo video)

Production Planning

Capacity Scheduling Table (+ demo video)

Convert Planned Orders

New Planning Strategy for Engineer-to-Order Processes Available

Enhanced Storage Location Determination

Optimized MRP Procedure for Time-Phased Planning

MRP Issues and Special Procurement Type in Monitor Material Coverage Apps

Time-Dependent Safety Stock and Reorder Point in Monitor Material Coverage Apps

Manage Material Coverage to Check Components Status during Order Conversion

BAdI for Modifying the Demand and Supply List (+ demo video)

Predictive Material and Resource Planning - Refresh Reference Data

DDR-Increased flexibility in calculating average daily usage and variability

Production Operations

Business Transaction Control for Process Orders

Create Production Order with Project

Manage Production Orders and Operations

External Personnel Number in Production/Process Order Information System

Confirm Production Operation

Quality Management

Integrating SAP Quality Issue Resolution with SAP S/4HANA Cloud (+ demo video)

Failure Mode and Effects Analysis

Manual Assignment of Certificate Profiles to Quality Certificates

Manage Inspection Lots app

Record Inspection Results app

Quality Inspections for Synchronous Goods Receipt Postings

Reset of Usage Decisions

Check out my video highlighting SAP Quality Issue Resolution:

Video 1: Highlight for Manufacturing in the 2208 release: SAP Quality Issue Resolution

Product Development

SAP Enterprise Product Development - Intelligent Handover

The Intelligent Handover in SAP Enterprise Product Development (EPD) enables production engineers to transform and restructure engineering bills of material (EBOMs) to manufacturing bills of material (MBOMs).

The diagram below shows the process overview of the Intelligent Handover.

Figure 1: EPD Intelligent Handover of EBOMs to MBOMs - Process Overview

In case of initial handover starting point for the production engineer is an EBOM in the SAP S/4HANA system that is released from the design engineer. By publishing the handover a corresponding MBOM will be created in the SAP S/4HANA system.

Once the EBOM has been handed over to a MBOM and the design engineer releases another change to the EBOM, the product engineer can also handover the BOM change to the corresponding MBOM.

Watch the next video which explains the steps of the handover process and shows in the system how to handover a BOM change.

Video 2: SAP Enterprise Product Development (EPD) - Intelligent Handover of EBOMs to MBOMs

(back to top)

Impact Analysis for Change Record

In the area of Engineering Change Management, Impact Analysis for Change Record helps you to identify the objects affected by an engineering change and thereby, evaluate the potential impact of the change. Using this feature, you can perform impact analysis on a change item and identify the impacted objects from the color-coded impact chart.

Watch the next video where my colleague Markus Oertelt sets up an impact analysis scenario using the Manage Impact Analysis Models app, performs an impact analysis for a change record, and in addition explains the configuration.

Video 3: Engineering Change Management - Impact Analysis for Change Record

(back to top)

Production Engineering

Process Production Versions

The new SAP Fiori app Process Production Versions is the one-stop solution for production versions that offers the following capabilities:

- View and edit existing production versions

- Create new production versions

- Mass lock and unlock of Production versions

- Mass consistency check of existing production versions

- View all proposals that are generated when a new production version if a new BOM / Task List is created or if a production version does not exist for a BOM/Task list combination

- Accept or Reject Proposals in a individual manner or through mass action

- Delete selected production versions

In the next video Markus shows you the new app in the system:

Video 4: New SAP Fiori app 'Process Production Versions'

As the icing on the cake, the app offers a network graph that visualizes the relationships of linked production versions.

Figure 2: New SAP Fiori app 'Process Production Versions' - Graph of Linked Production Versions

The next figure shows the self-service configuration UI (SSCUI) that has been introduced to configure the rules for the production version proposal.

Figure 3: 'Manage Your Solution' app - New configuration step 'Define Rules for Production Version Proposals'

(back to top)

Production Planning

Capacity Scheduling Table

The Capacity Scheduling Table app is the "heart" of capacity planning in SAP S/4HANA Cloud. So it's obvious that we constantly extend this app. With 2008, the following new features are available within the app:

- Navigate to the Variant Configuration screen (advanced variant configuration) to view the product configuration for the production orders (indicated by an icon) via App Extensibility.

- Add Custom Fields/columns/filters through the App Extensibility feature in the Additional Information tab of the Object Page.

- Check the Status Overview column for information on an order such as Dispatch status, Release status, Unsaved changes indicator, and Firmed order indicator.

- Check the Issues column for information on an order such as Overdue Indicator and Late Indicator.

In the next video Markus shows the new features in the system.

Video 5: 'Capacity Scheduling Table' app - App Extensibility, view product configuration, enhanced Status Overview and Issues information

(back to top)

Convert Planned Orders

With the Manage Planned Orders app, you can view the Long Text in the List Page entered during the creation of Planned Order.

While converting the Planned Order to a Production order or a Process Order, the long text will be copied to the newly created orders.

Figure 4: 'Manage Planned Orders' app - Long Text

(back to top)

New Planning Strategy for Engineer-to-Order Processes Available

With the past release, we introduced the new selection guide to find the right planning strategy group and offered 10 additional planning strategies and planning strategy groups (see my 2202 blog and Markus' blog post Manufacturing in SAP S/4HANA Cloud – Planning Strategies).

With 2208, the new planning strategy Sales from Project Stock Without Planning (E2) is available for covering engineer-to order processes. This planning strategy is used when sales is based on the project stock, that is when each product is specifically produced for a WBS element from your project management, for example, SAP Enterprise Portfolio and Project Management (EPPM). You use the project structure for collecting costs and to drive production planning based on the associated sales order items.

Figure 5: 'Manage Your Solution' app - Configuration step 'Display Planning Strategies' with new strategy 'E2' for Engineer-to-order production

(back to top)

Enhanced Storage Location Determination

The storage location determination has been enhanced to also allow for determination via production versions of phantom assemblies.

When working with phantom assemblies goods issues for components of the phantom assembly can be posted from the default production supply area (PSA) derived from the phantom assembly's production version.

For this purpose, the configuration step Define MRP Groups offers now the new strategies 5, 6 and 7 for storage location determination as shown in the next figure.

Figure 6: 'Manage Your Solution' app - Configuration step 'Define MRP Groups'

(back to top)

Optimized MRP Procedure for Time-Phased Planning

The time-phased planning procedure has been optimized allowing for an improved system performance when planning a high volume of materials using planning with a planning calendar.

If a vendor always delivers a material on a particular day of the week, it makes sense to plan this material according to the same cycle, in which it is delivered.

Materials that are planned using the time-phased planning technique are provided with an MRP date in the planning file. This date is set when creating a material master and is re-set after each planning run. It represents the date on which the material is to be planned again and is calculated on the basis of the planning cycle entered in the material master.

Time-phased planning can be executed using consumption-based planning or MRP.

The next figure shows for instance a time-phased planning scenario with regular deliveries on Wednesday and Friday and planning runs carried out on Monday and Tuesday.

The MRP run on Monday (see red time period below) plans the delivery for Friday by considering the planned delivery time (see black timeline below). The match of Friday's delivery with the result of Monday's MRP run is illustrated with the green bar.

The MRP run on Tuesday with the long planning period until Wednesday next week (see red time period above) makes sure that the delivery on Wednesday can be fulfilled illustrated by the green bar that matches Wednesday next week.

Figure 7: MRP time-phased planning procedure - Scenario with regular deliveries on Wednesday and Friday and planning runs carried out on Monday and Tuesday

Time-phased planning is usually used in the retail sector and is therefore an important requirement of the retail industry.

(back to top)

MRP Issues and Special Procurement Type in Monitor Material Coverage Apps

The Monitor Material Coverage - Net Segments and Monitor Material Coverage - Net and Individual Segments apps were enhanced with additional columns and filters to support you with identifying and handling MRP issues. In addition, special procurement types are now displayed in the material list and quick view.

Figure 8: 'Monitor Material Coverage' app - Past Due Elements

Figure 9: 'Monitor Material Coverage' app - Stock Day's Supply and Stock Intraday Supply

Figure 10: 'Monitor Material Coverage' app - 'Special Procurement Type' column on material list

Figure 11: 'Monitor Material Coverage' app - 'Special Procurement Type' field on object page

With this enhancements we provide the production planner using SAP Fiori apps with functionally they are get used to based on MRP lists (MD06).

The What's New document describes these enhancements in detail (see chapter 13.3.6.5.).

Additional enhancements were made to enable working with time-dependent safety stock and reorder points in the Monitor Material Coverage apps (see next chapter).

(back to top)

Time-Dependent Safety Stock and Reorder Point in Monitor Material Coverage Apps

The new threshold type Available Quantity Below Safety Stock with Reorder Point is now available for shortage definitions that can be used in the Monitor Material Coverage - Net Segments and Monitor Material Coverage - Net and Individual Segments apps. You can use material shortage definitions with this threshold type to determine how material shortages are displayed. If you select a

shortage definition with the new threshold type assigned, the stock availability chart reflects stock levels as follows:

- Green indicates that the stock level is equal to or above the reorder point defined for the material

- Yellow indicates that the stock level is below the reorder point, but equal to or above the safety stock defined for the material

- Red indicates that the stock level is below the safety stock that is defined for the material

Figure 12: Threshold type 'Available Quantity Below Safety Stock with Reorder Point' and color code of stock level

The next figure shows the configuration activity Define Material Shortage Profiles with the new option to select the threshold type Available Quantity Below Safety Stock with Reorder Point.

Figure 13: 'Manage Your Solution' app - Configuration activity 'Define Material Shortage Profiles' - new threshold type 'Available Quantity Below Safety Stock with Reorder Point'

In addition, the new columns Safety Stock, Reorder Point, and MRP Safety Stock Method were added to the material overview table and the stock availability chart was adapted to reflect time-dependent safety stock levels defined in the Maintain Time-Dependent Stock Levels app.

Figure 14: 'Monitor Material Coverage' app - stock availability chart reflects time-dependent safety stock levels

Figure 14: 'Monitor Material Coverage' app - stock availability chart reflects time-dependent safety stock levels

(back to top)

Manage Material Coverage to Check Components Status during Order Conversion

In the Manage Material Coverage app, you can convert planned orders into production orders or process orders.

If warnings are issued for the components of a material based on their material status, you can use this feature to select whether you want to include these components in an order or not.

You can also check for material components that are blocked from conversion due to their material status.

Figure 15: 'Manage Material Coverage' app - Convert Planned Order

(back to top)

BAdI for Modifying the Demand and Supply List

With 2208, we offer the first Business-Add In (BAdI) for Material Requirements Planning. Technically this is an AMDP (ABAP Managed Database Procedures) BAdI.

The Business-Add In (BAdI) PPH_SUPPLY_DEMAND_LIST has been made available for developer extensibility. It is used to remove or change standard MRP elements or add custom MRP elements to the supply and demand list in order to adapt MRP to your company’s needs. The changes are considered by the MRP run and they are displayed in the MRP apps.

In the following demo video I explain the example implementation for adding MRP elements, in this case to reduce stock for expiring products and show the impact of the BAdI implementation on a MRP run using a simple example.

Video 6: Business Add-In 'Modification of Supply and Demand List'

Note: The AMDP BAdI is only available for customers with a 3-System Landscape (3SL). The 3SL architecture introduces a development tenant into the landscape and will offer our customers and partners enhanced extensibility via in-app development with the SAP S/4HANA Cloud, ABAP Environment, (aka embedded steampunk). For further information read the blog post Embedded Steampunk – Some more details for ABAP developers.

(back to top)

Predictive Material and Resource Planning - Refresh Reference Data

In the Process pMRP Simulations app you can update specific stock, demand and constraint quantities and use the updated data for your simulations based on the same reference without the need to schedule a new simulation creation from scratch.

Figure 16: Process pMRP Simulations app - Refresh Reference Data

(back to top)

DDR-Increased flexibility in calculating average daily usage and variability

A year ago, I last presented a major improvement in the area of Demand Driven Replenishment (DDR) for support of repetitive manufacturing (see my 2108 blog). Following many customer requests for more flexibility in calculating important parameters for buffer positioning (XYZ classification) and buffer sizing (ADU and variability factors), we now deliver the next very useful enhancement for DDR:

The apps Schedule Product Classification (DD) and Schedule Buffer Proposal Calculation enable you to exclude the days when no goods issues took place for the material in the related background jobs to schedule product classification and schedule buffer proposal calculation. The next two screenshots show the new flag Exclude Non Goods Issue Days in both apps.

Figure 17: 'Schedule Product Classification (DD)' app - Exclude Non Goods Issue Days

Figure 18: 'Schedule Buffer Proposal Calculation' app - Exclude Non Goods Issue Days

(back to top)

Production Operations (Execution and Control)

Business Transaction Control for Process Orders

With the past release, we enabled business transaction control for production orders (see my 2202 blog).

In addition, you can now control which business transactions are allowed for a process order or an order operation depending on other business transactions that are executed.

This function is available in all apps that make changes to process orders, for example,

- Manage Process Orders (F4587),

- Create Process Order With Material (COR1)

- Create Process Order With a Planned Order (COR7)

- Release Process Orders (COR5)

- Confirm Process Order (CORK)

The following configuration steps are relevant for the Business Transaction Control:

- Define Business Transaction Control - Make settings for blocking certain business transactions for a status profile either immediately or when other business transactions are executed.

- Define Process Order Types - Assign the status profile to the order header.

(back to top)

Create Production Order with Project

You can use the Create Production Order with Project app to create a production order for project stock within engineer-to-order production.

Figure 19: 'Create Production Order with Project' app

The Manage Material Coverage app displays in the Individual Segment field that this is a production order for project stock within engineer-to-order production as shown in next screenshot. Most often users navigate from the Monitor Material Coverage app to the Manage Material Coverage app, but you can also call the Manage Material Coverage app directly from Fiori launchpad tile Check Material Coverage.

Figure 20: 'Manage Material Coverage' app - Individual Segment: Project Stock

(back to top)

Manage Production Orders and Operations

In the Manage Production Orders app the issue types are enhanced with Failed Material Movements in the filter, worklist and issue summary in the detailed page as shown in the figure below.

Also the navigation to the Reprocess Failed Material Movements application is supported.

Figure 21: 'Manage Production Order' app - Issue Type 'Failed Material Movements'

Moreover, the production supervisor apps Manage Production Orders and Manage Production Operations enable you now to display and filter user-defined statuses for production orders and operations in the worklist. By using user-defined statuses, you can control which business transactions are enabled or disabled for a production order in a certain status.

Worklists and details page are enhanced with Related Apps button, navigates to order-specific apps as well as other order-related apps.

(back to top)

External Personnel Number in Production/Process Order Information System

You can display external personnel numbers in the Confirmations list in both the Monitor Production / Planned Orders app and the Monitor Process / Planned Orders app.This is useful, for example, if you want to display the external personnel numbers of employees who have entered confirmations for certain production orders. On the output list, change the layout to include the column Work Agreement External ID.

Figure 22: Order Informations System - External personnel number

(back to top)

Confirm Production Operation

With the Confirm Production Operation app, a production operator can partially or completely confirm production operations. When you have entered the order and operation number for confirmation the system proposes data for quantities and activities by default. You can now configure that the system shall not propose those values automatically. To actively request them, you use the Get Proposals button. If you have overwritten the proposed values and want to reset them, you can also use the Get Proposals button.

Figure 23: 'Confirm Production Operation' app - new 'Get Proposals' button

(back to top)

Quality Management

Integrating SAP Quality Issue Resolution with SAP S/4HANA Cloud

SAP Quality Issue Resolution is an interactive platform to support you with solving and preventing quality issues. It is the successor of SAP Supplier Problem Solving (see my 2202 blog) and runs on BTP (SAP Business Technology Platform). SAP Quality Issue Resolution uses the 8D methodology for a team-oriented problem-solving approach.

Starting point of the 8D problem-solving process with SAP Quality Issue Resolution is the quality notification in SAP S/4HANA Cloud. From the action box in the notification, you can trigger creation of a new 8D. Information such as material number, defect details, and business partner are transferred from the quality notification to SAP Quality Issue Resolution.

With 2208 release, the integration between quality notification in S/4HANA Cloud and SAP Quality Issue Resolution is provided. The next figure illustrates the integration between SAP Quality Management in S/4HANA Cloud and SAP Quality Issue Resolution running on BTP.

You can request the 8D problem-solving for

- Supplier from quality notification of type Q2 and

- Customer Complaint from quality notification of type Q1.

Figure 24: Integration between quality notification in S/4HANA Cloud and SAP Quality Issue Resolution

The next video shows you the 8D problem-solving process in case of Complaint Against Supplier:

Video 7: SAP Quality Issue Resolution - 8D problem-solving process for Complaint Against Supplier

(back to top)

Failure Mode and Effects Analysis (FMEA)

In my 2202 blog I highlighted the Failure mode and effects analysis (FMEA).

With 2208, we deliver the following FMEA enhancements:

New Self-Service Configuration UIs

The following figure shows the FMEA configuration steps that are available with the 2208 release. The figure highlights explicitly step 3 that allow you to define your own FMEA type.

Figure 25: 'Manage Your Solution' app - New FMEA configuration steps e.g. 'Define FMEA Types'

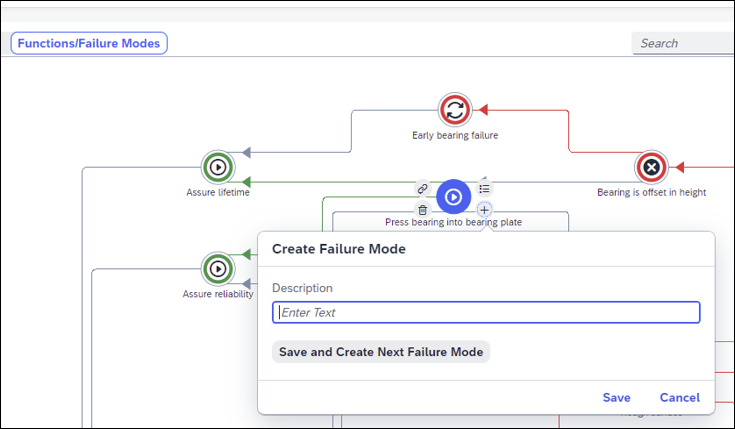

Manage FMEAs app

The following changes were made in the Manage FMEAs app:

- New Sub Object Page for FMEA Actions

You can now navigate from the Optimization page to FMEA Action sub object page (display only) that displays the context relevant information of FMEA actions.

- Figure 26: 'Manage FMEAs' app - New Sub Object Page for FMEA Actions

- Create Multiple Failure Modes in the Graphic in one go

You can now create multiple failure modes in the graphic in one go. Figure 27: 'Manage FMEAs' app - Create Multiple Failure Modes

Figure 27: 'Manage FMEAs' app - Create Multiple Failure Modes

- New Master Detail View

The graphic on the left was replaced by a list. Figure 28: 'Manage FMEAs' app - New Master Detail View

Figure 28: 'Manage FMEAs' app - New Master Detail View

FMEA Cockpit & FMEA Monitor - Risk Analysis Using Risk Matrixes

You can use this feature to run a risk analysis for the causes in an FMEA based on detection actions and preventive actions and the severity of failure modes, and represent the risk using risk matrixes. The risk analysis is based on the action priority method. You can start the risk analysis for one or more FMEAs from the FMEA monitor and from the FMEA cockpit.

Figure 29: 'FMEA Cockpit - Display FMEA' calls 'FMEA Monitor - Risk Analysis'

The following new configuration activities are relevant for risk matrixes:

- Define Risk Matrixes

- Define Risk Analysis Profiles

(back to top)

Manual Assignment of Certificate Profiles to Quality Certificates

With 2202 Release, the apps “Manage Quality Certificates for Batches” and “Manage Quality Certificates for Inspection Lots” were enhanced with an automatic certificate profile determination. Based on the customer requirement not to be forced to maintain condition records for using these apps, a further enhancement is introduced with this release.

In case there are no matching entries available in the condition tables in app “Process Certificate Profile Assignment”, you can select the profile directly while creating the quality certificate in these apps.

Please find screenshots below illustrating this enhancement in app Manage Quality Certificates for Inspection Lots.

Figure 30: 'Manage Quality Certificates for Inspection Lots' app - Create Certificate

In case a condition record is determined the certificate profile data is automatically filled. You can change the entries manually if needed.

Figure 31: 'Manage Quality Certificates for Inspection Lots' app - Certificate profile data is automatically filled if condition record is determined

(back to top)

Manage Inspection Lots app

Filter for Created Inspection Lots

For Inspection Lot Status the status Created is now available as filter criteria. This helps to identify inspection lots which need attention before results recording can start.

Figure 32: 'Manage Inspection Lots' app - Filter for Created Inspection Lots

(back to top)

Record Inspection Results app

With the 2108 release, the new Record Inspection Results app was introduced as the successor of the Record Inspection Results (Deprecated) app (see my 2108 blog).

With the Record Inspection Results app, you can now:

- Filter inspection lots and operations by work center on the worklist page

Figure 33: 'Record Inspection Results' app - Filter for Work Center

Figure 33: 'Record Inspection Results' app - Filter for Work Center

- Display the Material field on the characteristic result details screen

Figure 34: 'Record Inspection Results' app - Material on Inspection Results Detail Screen

Figure 34: 'Record Inspection Results' app - Material on Inspection Results Detail Screen

- Display the inspection method on the results recording characteristic details screen

Figure 35: 'Record Inspection Results' app - Display Inspection Method

Figure 35: 'Record Inspection Results' app - Display Inspection Method

However, it is not possible to display the inspection method in a separate window.

- Automatically add rows for single results on the characteristic result details screen based on the inspection scope of the lot

Figure 36: 'Record Inspection Results' app - Automatically add rows for single results

Figure 36: 'Record Inspection Results' app - Automatically add rows for single results

- View the material and plant combination for the defect on its object page

Figure 37: 'Record Inspection Results' app - Material and Plant for Defects from Results Recording

Figure 37: 'Record Inspection Results' app - Material and Plant for Defects from Results Recording

- Add attachments and links to the inspection characteristics

Figure 38: 'Record Inspection Results' app - Attachments for Inspection Characteristic Results

Figure 38: 'Record Inspection Results' app - Attachments for Inspection Characteristic Results

(back to top)

Quality Inspections for Synchronous Goods Receipt Postings

With this feature, you can directly post synchronous goods receipts from other parts of SAP S/4HANA Cloud into Warehouse Management for goods procured externally or goods from in-house production. The system creates an inspection lot when a goods receipt is posted for a product that’s inspection-relevant, for example, in the Post Goods Movements app. This feature is also described in the blog post Supply Chain in SAP S/4HANA Cloud 2208.

Figure 39: Inspection lot creation for synchronous goods receipt postings

(back to top)

Reset of Usage Decisions

You probably know the possibility to change a usage decision for inspection lots in S/4HANA Cloud. But in some cases, changing the usage decision might not be sufficient and you want to delete the previously recorded usage decision. To meet this requirement a new Reset Usage Decision button is available now in Manage Usage Decision app.

Figure 40: 'Manage Usage Decision' app - Reset Usage Decision

To activate the Reset Usage Decision button, maintain configuration step 102456 Maintain Settings at Plant Level.

(back to top)

Thanks for reading this blog post. Stay tuned!

You will find a collection of my SAP S/4HANA Cloud release blogs here:

My colleague Markus Oertelt writes an interesting blog series about

Discrete Industries in SAP S/4HANA Cloud.

For more information on SAP S/4HANA Cloud, check out the following links:

- SAP S/4HANA Cloud release info here

- Sven Denecken’s SAP S/4HANA Cloud 2208 Release Blog

- SAP S/4HANA Cloud 2208 Early Release Series Webinars here

- Latest SAP S/4HANA Cloud Release Blogs here

- Product videos on our SAP S/4HANA Cloud and SAP S/4HANA YouTube playlist

- Inside SAP S/4HANA Podcast here

- Best practices for SAP S/4HANA Cloud here

- SAP S/4HANA Cloud Community: here

- Feature Scope Description here

- What’s New here

- Help Portal Product Page here

- Implementation Portal here

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn

- SAP Managed Tags:

- SAP S/4HANA Cloud for Manufacturing,

- SAP S/4HANA,

- SAP S/4HANA Public Cloud

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

152 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

208 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

88

Related Content

- Building Low Code Extensions with Key User Extensibility in SAP S/4HANA and SAP Build in Enterprise Resource Planning Blogs by SAP

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

- Unable to add the event filters in the Event Enablement Channel in Enterprise Resource Planning Q&A

- How to check if a note is applied in S4HANA Public Cloud? in Enterprise Resource Planning Q&A

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 6 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |