- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP PLM integration with CATIA business process te...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Narasimha

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-29-2022

4:12 AM

Purpose: Continued from a previous blog post, Continue to view the business process capabilities of Catia and SAP PLM integration (Document structure creation and Material BOM creation)

Prerequisites: SAP PLM integration with CATIA business process testing steps- 1

Best practices: ECTR is the current solution for SAP PLM integration with CAD drawings. If You liked this blog post, learn about ECTR in this wiki.

In this blog post, we will continue to see the capabilities of Catia - SAP PLM integration. In the last blog post, you saw how you can create a DIR and material master with Catia- SAP PLM integration and how Catia drawing could be renamed to DIR number -Document type- Document part.

In this blog post, you will see how you can create Doc Structure from an Assembly and creating Material BOM.

This way, by using Catia- SAP PLM integration, you will be able to create material, DIR, Document structure and material BOM and see synchronous updates in Catia Drawing.

In the following final Blog post, I will explain BOM and DIR edits.

Based on your feedback on this blog post, I will try to cover many such PLM integration topics.

Best practices: ECTR is the current solution for SAP PLM integration with CAD drawings. If You liked this blog post, learn about ECTR in this wiki.

Prerequisites: SAP PLM integration with CATIA business process testing steps- 1

Best practices: ECTR is the current solution for SAP PLM integration with CAD drawings. If You liked this blog post, learn about ECTR in this wiki.

In this blog post, we will continue to see the capabilities of Catia - SAP PLM integration. In the last blog post, you saw how you can create a DIR and material master with Catia- SAP PLM integration and how Catia drawing could be renamed to DIR number -Document type- Document part.

In this blog post, you will see how you can create Doc Structure from an Assembly and creating Material BOM.

| Function | Step | Step Description | Expected Result |

| Creation of Doc Structure from an Assembly | (a) Close the open file(s) in CATIA V5. (b) Open an existing CATIA V5 assembly containing at least 2 parts. (c) Switch to CAD View by selecting SAPPLM > CAD Desktop > CAD View. (d) Select the row containing the assembly in CAD View. (e) Create documents for all 3 records by selecting Create > Create (All) Documents Data Assembly_ABC.CATProduct, containing PartABC01.CATPart and PartABC02.CATPart | (i) In CAD View, 3 Documents should be created with system generated document numbers. (ii) A check mark should be seen on each record, indicating the documents are ready for check-in. (iii) User-given file names should be seen in the corresponding Description fields. (iv) The Assembly structure should be seen replicated under the Doc-Based Structure. | |

| |||

| Creation of Doc Structure from an Assembly | 2 | (a) Select all the document records in CAD View that are ready for check-in and check it in, by selecting Originals > Check In Original (b) Select ZXXXX as the storage category, when prompted Test Data Document # 30000239, 30000240, 30000241 Storage Category: ZXXXX | The documents should be checked in (the check mark on the records go away and the icons change) |

. . | |||

| Material BOM Creation | 1 | (a) Select all the relevant document records, and create associated Materials by selecting Material > Create in Background. Test Data Document # 30000239, 300000240, and 30000241 | Materials associated with the documents should be created. |

| |||

| Material BOM Creation | 2 | (a) Select the top document record that corresponds to the Assembly file (b) Create the Material BOM by selecting Material BOM > Create/Change Test Data Header Material # 1000000155 | A Create/Change Material BOM GUI should pop up. |

| |||

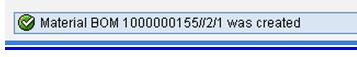

| Material BOM creation | 3 | (c) With Usage value as 2 (Engineering BOM ) and no value in the Plant field, click on continue action. Test Data Header Material # 1000000155 | A Material BOM created appears in the status bar. A Material BOM should be created for the Material. |

See actual BOM in CS03 Tcode

| |||

This way, by using Catia- SAP PLM integration, you will be able to create material, DIR, Document structure and material BOM and see synchronous updates in Catia Drawing.

In the following final Blog post, I will explain BOM and DIR edits.

Based on your feedback on this blog post, I will try to cover many such PLM integration topics.

Best practices: ECTR is the current solution for SAP PLM integration with CAD drawings. If You liked this blog post, learn about ECTR in this wiki.

- SAP Managed Tags:

- PLM (Product Lifecycle Management)

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- ISAE 3000 for SAP S/4HANA Cloud Public Edition - Evaluation of the Authorization Role Concept in Enterprise Resource Planning Blogs by SAP

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- Update of the SAP Activate Roadmap for SAP S/4HANA (on prem) upgrades with the Clean Core Strategy in Enterprise Resource Planning Blogs by SAP

- Business Volume Report shows Billing Documents that do not accrue to the contract in Enterprise Resource Planning Q&A

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |