- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP IBP: Applying Machine Learning and Artificial ...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ankuagra

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-17-2022

7:21 AM

Dear SAP Friends,

Happy Reading !!!!!!!!

Welcome to one of the Interesting Topic in SAP “Integrated Business Planning”

AI/ML is the buzz words of the town, and the world is more moving towards the automation, digitalization, digital twin, etc. While working on some of the opportunities in the supply chain planning, I thought to pen down some of my understanding of artificial intelligence and machine learning in context of SAP IBP – SAP Integrated Business Planning.

Artificial intelligence is a wider term and applied to almost everywhere in industries like automobile, aerospace, pharma, etc. Machine Learning is a sub part of overall value chain of artificial intelligence.

What does Machine Learning means, it is basically, machines performs tasks which are repetitive in nature. Machines are intelligent enough that we no need to instruct them all the time but they can adapt to different situations. Machine Learning is a behaviour of machines where it can process the data / instructions automatically and can learn on their own without involvement of any person.

Some of real-life examples are:

From the idea of machine learning from the day-to-day life let’s explore the usage of machine learning in the space of SAP IBP. Presently Machine Learning is explored in IBP in the below mentioned areas (not limited to in future)

Demand Planning : To get more accurate forecast

Demand Sensing : Pattern recognition in short term forecast

Supply Planning : To address the supply capacity constraints

Exception Management : Alert Clustering

Automation : Process automation for jobs

Data Reliability : Data validation

Demand Planning having Time Series Analysis which try to give the information about the data the system is loaded with using the pattern recognition by machine learning. There are pre-build algorithms to identify the global shifts and trend shifts.

With SAP IBP Time series analysis, a user can check for the below data patterns:

Time-series analysis and change point detection are powerful tools. As a demand planner one can identify patterns in individual time series such as Trend, Seasonality, Continuous, and Irregular as well as significant changes, for example, level shifts where the mean of the time series values alters significantly or trend changes where the direction or slope of a trend alters significantly.

Based on these reflections, planners can select the best suitable forecast algorithms. Planners can further analyze these results together with those from ABC segmentation and demand forecast accuracy to better understand the structure of the underlying data.

Let’s understand, how we can utilize SAP IBP algorithm to recognise the pattern using machine learning.

Gradient Boosting of Decision Trees – It enables machine learning technique for regression and classification problems.

The goal of the algorithm is to predict a target variable from a set of input variables and their attributes. The approach builds a tree structure through a series of binary splits (yes/no) from the root node via branches passing several decision nodes (internal nodes), until we come to leaf nodes.

You can run the Forecasting Job from Fiori or through the SAP IBP Excel Add-in

The algorithm can find out that if any of the two variables, then sales increase as well, but if both of them increase at the same time, then sales drop. Get more details on the Gradient Boosting of Decision Trees in blog

Demand Sensing is basically looking at historical patterns as well as external data and coming up with a short-term forecast using this exclusive algorithm. Applying machine learning in demand sensing uses different regression algorithms to identify patterns as well as the relationships between the data that you have and the data coming from external sources. It will be based on the gradient boosting.

The algorithm also has some advantages compared to the demand sensing (full) algorithm:

Check more details on SAP Help – Demand Sensing with Gradient Boosting

Supply Planning Presently doesn’t have direct algorithm to use supply planning optimization using machine learning. There can be scenario where one can have a use case for capacity planning. The constraints of the capacity planning will be considered during the supply optimization run.

A use case can be as, IoT devices from the floor automations gives signals when any mechanical resource going beyond tolerance limits, results to unavailability of the resource capacity due to resource outage. Supply optimizer understands the unavailability of the specific resource and replan the production.

Exception Management Alerts are generated to indicate specify abnormal situations asises along the supply chain such as material shortages, supply shortage, inadiquate capacity, requested date violations or KPI values beyond the tolerance limits.

Alerts supports supply chain planners to bring their attention to the specific situation arises in the supply chain which is not normal. Tools like the Alert Monitor in SAP IBP and formerly SAP APO intend to channel all the issues in an efficient way.

Unfortunately, the high number of alerts often stops the planner from seeing the specific problem which required to be addressed on priority. This may be due to missing filters or numerous alert types or just too many alerts generated in the system.

The task for Machine Learning here would be to identify patterns or data clusters – in case of time series – predictions for the future without prework of a planner to adjust the algorithm parameters or spending a lot of time to adjust the history outliers.

SAP IBP introduces here Machine Learning algorithms to support an automation of filtering and clustering of the supply chain alerts. Two Machine Learning algorithms are available in current IBP release, which are in general classified as clustering algorithms:

Holistically, applying both Machine Learning algorithms, K-Means and DBSCAN, for custom alerts in SAP IBP are useful to compress alerts on a large scale to a manageable number, which in turn means an excellent support for the planner to focus on the specific problem positions.

Data Reliability Machine learning can help in learn semantic rules to identify problems in master data and recommend values for correction. This helps reduce manual efforts of planners or data team in preparing data for planning.

Machine learning for data consistency is run as an application job using the job template - Machine Learning Master Data Consistency.

Machine learning can identify the semantic relations and patterns in master data and derive association rules. From the derived rules, the algorithm identifies outliers with higher probability and recommends values for the outliers.

From the generated rules and recommendations, planners can decide whether rules are adhere to organization's policy or requirements, and if the generated outliers and recommendations are valid, then planners can make relevant changes to the master data, either in the source system like S4 HANA or ECC or in SAP IBP. The algorithm can be executed once, or periodically.

Automation - Using Machine Learning in job scheduling - Using machine learning for batch jobs can help to detect discrepancies in job duration and allows to review the job schedules.

The Outlier Jobs Detection job template uses a machine learning algorithm, namely the density-based clustering algorithm (DBSCAN), to determine the outlier jobs.

The algorithm uses the job name and the job duration and analyses logs of the executed application jobs that are still available in the system.

hope this blog post on SAP IBP using Machine Learning provide resourceful information and helps on the way to gain knowledge and upskill about advance additions. Most importantly, you will learn how use the advance features with real-time supply chain planning capabilities.

For more information on your SAP IBP solution, please visit the community page. Here you will be able to leverage powerful supply chain analytics, what-if simulations, alerts, SAP news, SAP customer stories and other resources to stay ahead and ensure business continuity.

If you have remaining questions and need further guidance, navigate to SAP’s Ask a Question site to receive answers from SAP IBP experts.

Or to get more details about SAP IBP capability, please refer to the SAP Product portfolio

Happy Reading !!!!!!!!

Welcome to one of the Interesting Topic in SAP “Integrated Business Planning”

AI/ML is the buzz words of the town, and the world is more moving towards the automation, digitalization, digital twin, etc. While working on some of the opportunities in the supply chain planning, I thought to pen down some of my understanding of artificial intelligence and machine learning in context of SAP IBP – SAP Integrated Business Planning.

Artificial intelligence is a wider term and applied to almost everywhere in industries like automobile, aerospace, pharma, etc. Machine Learning is a sub part of overall value chain of artificial intelligence.

What does Machine Learning means, it is basically, machines performs tasks which are repetitive in nature. Machines are intelligent enough that we no need to instruct them all the time but they can adapt to different situations. Machine Learning is a behaviour of machines where it can process the data / instructions automatically and can learn on their own without involvement of any person.

Some of real-life examples are:

- Human language recognition like Alexa or Siri to perform the tasks based on your instructions

- Spam filters in your Gmail or Outlook to alert you for the mails based on some pre-defined criteria

- Shopping websites trying to classify products based on your visits and propose the products to you

- Image identification and object recognition

From the idea of machine learning from the day-to-day life let’s explore the usage of machine learning in the space of SAP IBP. Presently Machine Learning is explored in IBP in the below mentioned areas (not limited to in future)

Demand Planning : To get more accurate forecast

Demand Sensing : Pattern recognition in short term forecast

Supply Planning : To address the supply capacity constraints

Exception Management : Alert Clustering

Automation : Process automation for jobs

Data Reliability : Data validation

Demand Planning having Time Series Analysis which try to give the information about the data the system is loaded with using the pattern recognition by machine learning. There are pre-build algorithms to identify the global shifts and trend shifts.

With SAP IBP Time series analysis, a user can check for the below data patterns:

- Trend

- Seasonality

- Intermittency & Volatility

- Lumpy

- Continuous

Time-series analysis and change point detection are powerful tools. As a demand planner one can identify patterns in individual time series such as Trend, Seasonality, Continuous, and Irregular as well as significant changes, for example, level shifts where the mean of the time series values alters significantly or trend changes where the direction or slope of a trend alters significantly.

Based on these reflections, planners can select the best suitable forecast algorithms. Planners can further analyze these results together with those from ABC segmentation and demand forecast accuracy to better understand the structure of the underlying data.

Time Series process flow

- Time Series analysis can be used to understand the pattern and characteristics such as seasonality, trends in data to generate an accurate statistical forecast with the combination of attributes like location, product, customer & brand.

- Planner can set the conditions to test each of the data pattern and how the system should analyse data to provide the results. Result of the analysis will be the pattern of data as a pre-defined text and the average demand interval and seasonal indices at each level.

- Results of time series analysis can be used with a best-fit forecast model profile and let the system to choose the appropriate best fit model. A planner can then use the filters in SAP IBP Assign Forecast Models application to see results of Time Series Analysis.

- Results of time series analysis can be also used for segmentation of products & understanding the root causes of changes in sales pattern.

Let’s understand, how we can utilize SAP IBP algorithm to recognise the pattern using machine learning.

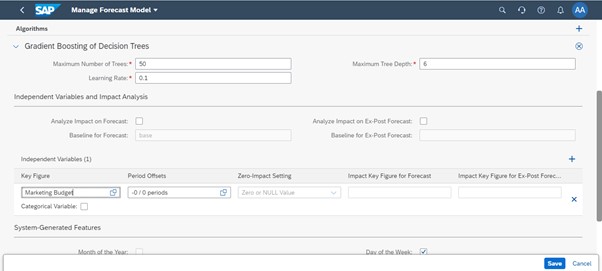

Gradient Boosting of Decision Trees – It enables machine learning technique for regression and classification problems.

The goal of the algorithm is to predict a target variable from a set of input variables and their attributes. The approach builds a tree structure through a series of binary splits (yes/no) from the root node via branches passing several decision nodes (internal nodes), until we come to leaf nodes.

SAP IBP Manage Forecast Model

You can run the Forecasting Job from Fiori or through the SAP IBP Excel Add-in

The algorithm can find out that if any of the two variables, then sales increase as well, but if both of them increase at the same time, then sales drop. Get more details on the Gradient Boosting of Decision Trees in blog

Demand Sensing is basically looking at historical patterns as well as external data and coming up with a short-term forecast using this exclusive algorithm. Applying machine learning in demand sensing uses different regression algorithms to identify patterns as well as the relationships between the data that you have and the data coming from external sources. It will be based on the gradient boosting.

The algorithm also has some advantages compared to the demand sensing (full) algorithm:

- It has greater forecast accuracy throughout the short-term horizon

- It is not dependent on open orders as a signal for accuracy improvement

- It can process historical only or historical and future extra signals

Check more details on SAP Help – Demand Sensing with Gradient Boosting

Supply Planning Presently doesn’t have direct algorithm to use supply planning optimization using machine learning. There can be scenario where one can have a use case for capacity planning. The constraints of the capacity planning will be considered during the supply optimization run.

A use case can be as, IoT devices from the floor automations gives signals when any mechanical resource going beyond tolerance limits, results to unavailability of the resource capacity due to resource outage. Supply optimizer understands the unavailability of the specific resource and replan the production.

Exception Management Alerts are generated to indicate specify abnormal situations asises along the supply chain such as material shortages, supply shortage, inadiquate capacity, requested date violations or KPI values beyond the tolerance limits.

Alerts supports supply chain planners to bring their attention to the specific situation arises in the supply chain which is not normal. Tools like the Alert Monitor in SAP IBP and formerly SAP APO intend to channel all the issues in an efficient way.

Unfortunately, the high number of alerts often stops the planner from seeing the specific problem which required to be addressed on priority. This may be due to missing filters or numerous alert types or just too many alerts generated in the system.

Alert Clustering

The task for Machine Learning here would be to identify patterns or data clusters – in case of time series – predictions for the future without prework of a planner to adjust the algorithm parameters or spending a lot of time to adjust the history outliers.

SAP IBP introduces here Machine Learning algorithms to support an automation of filtering and clustering of the supply chain alerts. Two Machine Learning algorithms are available in current IBP release, which are in general classified as clustering algorithms:

- K-Means

- DBSCAN

SAP IBP Create Custom Alerts

Holistically, applying both Machine Learning algorithms, K-Means and DBSCAN, for custom alerts in SAP IBP are useful to compress alerts on a large scale to a manageable number, which in turn means an excellent support for the planner to focus on the specific problem positions.

Data Reliability Machine learning can help in learn semantic rules to identify problems in master data and recommend values for correction. This helps reduce manual efforts of planners or data team in preparing data for planning.

Machine learning for data consistency is run as an application job using the job template - Machine Learning Master Data Consistency.

Machine learning can identify the semantic relations and patterns in master data and derive association rules. From the derived rules, the algorithm identifies outliers with higher probability and recommends values for the outliers.

From the generated rules and recommendations, planners can decide whether rules are adhere to organization's policy or requirements, and if the generated outliers and recommendations are valid, then planners can make relevant changes to the master data, either in the source system like S4 HANA or ECC or in SAP IBP. The algorithm can be executed once, or periodically.

Application Job – ML Master Data Consistency

Automation - Using Machine Learning in job scheduling - Using machine learning for batch jobs can help to detect discrepancies in job duration and allows to review the job schedules.

The Outlier Jobs Detection job template uses a machine learning algorithm, namely the density-based clustering algorithm (DBSCAN), to determine the outlier jobs.

The algorithm uses the job name and the job duration and analyses logs of the executed application jobs that are still available in the system.

Application Job – Outlier Jobs Detection

hope this blog post on SAP IBP using Machine Learning provide resourceful information and helps on the way to gain knowledge and upskill about advance additions. Most importantly, you will learn how use the advance features with real-time supply chain planning capabilities.

For more information on your SAP IBP solution, please visit the community page. Here you will be able to leverage powerful supply chain analytics, what-if simulations, alerts, SAP news, SAP customer stories and other resources to stay ahead and ensure business continuity.

If you have remaining questions and need further guidance, navigate to SAP’s Ask a Question site to receive answers from SAP IBP experts.

Or to get more details about SAP IBP capability, please refer to the SAP Product portfolio

- SAP Managed Tags:

- SAP Integrated Business Planning for Supply Chain

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Asset Performance Management Embedding Cumulocity IoT to Drive Innovations in IoT and AI in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 4 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |