- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- SAP for R&D/Engineering and PLM: The Dilemma of ha...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

bernhard_meyer

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-14-2022

4:27 PM

I am Bernhard Meyer from the global industrial manufacturing team focusing on the product development and product lifecycle part of our customers value chain, but having at the same time the entire value chain on the radar. In this blog post, I will talk about the challenge our prospects and customers, as well many advising solution architects have, when identifying the best “PLM” option in the SAP context for their needs. The following is reflecting my opinion, but as always, I try to “paint” a picture in black and white to keep it simple, knowing the world is of course grey.

Depending on the context, many different dilemmas can pop-up, but I think there are only a few which are always present:

Still too many customers and prospects see SAP as a pure ERP vendor. This opinion is true, if they would life in 1990’s, but we have 30 years later and we talk about comprehensive end-to-end scenarios like “design-to-operate”, where the ERP is just a single and of course important piece of the puzzle, beside of many other products and solutions SAP is providing.

According to the customer organization, we mainly talk to buying centers, means to professionals seeing their specific needs and often not thinking cross company. As a young business consultant, I was engaged at KRONES. Mr. Islinger, one of the leading managers, brought the challenge on a simple page. “Either the starting point is the center line on a construction drawing or it is the business material”.

Knowing that may the manual painted construction drawing is not any more the state of the art, it shows what the DNA of the different thinking is. And this is not about good or bad, because both is required at the same time, depending on the different end-to-end scenario flavors.

Finally, I see the different SAP provided reasonable options as a difficulty. To be honest, ask 10 experts and you will get 20 (somehow) different (and in their context correct) answers.

As an advising person, independent on customer, on partner, or on SAP side, we must provide the best solution for the appropriate customer situation and needs and not choices.

But how to come to this “best solution”?

First, this kind of discussions cannot be done on high- or low-level, because the high-level does not provide the required insides to draw conclusions, whereas the low-level approach is too detailed and hinders fruitful conversations.

Secondly the high-level is often not enough industry related and therefore not as accurate as required by the customers and the “low”-level is too much product and technology related.

So, to find the “mid”-level is key. This is the level where customer specific and industry segment content becomes relevant.

But what contains this mid-level?

It must be …

Mentally distinguish between the customer order processes types and the logistical principles to fulfill the customer order. I talk here about the manufacturing industries, but this can be partly transferred to other industries as well. By the way something, I learnt from Prof. Dr. Jörg W. Fischer years ago.

Think about, what is for your customer relevant and deviate the impact from an R&D/Engineering and Product Lifecycle Management (PLM) point of view. E.g. Configure-to-Order (CTO) means standardization, so how to standardize the product portfolio or Engineer-to-Order (ETO) is always heavily related to engineering change management?

It is of course a black and white illustration, and, in the reality, all types can be found at customer side at the same time, depending on their product and solution portfolio. Nevertheless, it helps to get to the point.

For the sake of simplicity, I always start with the ERP system in the middle and then enhance it in the direction of engineering, production, and service according to the requirements.

The key question is, are the ERP system capabilities basically able, to serve the above-described customer order processing types and logistical principles in the specific customer situation?

The ERP system is for me like the glue, which holds everything together.

Next question is :

“What is triggering the processes in the ERP system?”

From a R&D/Engineering point of view, this is mainly the material. Basically, we need material masters and logistical bill of materials in the ERP system as a starting point. How can these material masters and logistical bill of material created in an automated manner?

Which capabilities are required from a Product Lifecycle Management point of view?

The same question is going in the direction of production :

“What must be handed-over to production (plant specific logistical bill of material)?” and

”What is triggering the production (demand)? Only forecasts or as well customer- and project-driven demands?”

And now, what makes the design-to-operate process complex? It is the overall process flow.

For the Select-to-Order (SFS) and Configure-to-Order (CTO) processes, the process flow is always straight forward, from “left to right”. This means, from a product perspective, everything is defined, materials in the ERP systems are created, suppliers are identified, production engineering is done, and so on.

A bit more challenging is the Configure-to-Order PLUS (CTO+) and Engineer-to-Order (ETO) processes because the additional customer requirements lead in a for- and backward between engineering and production.

Whereas the SFS and CTO lead in a minor technical and commercial risk, the CTO+ and ETO scenario increasing this kind of risks, which of course leads in more sophisticated capabilities to mitigate these risks, which by the way is the reason, why more accurate financial and logistical capabilities are required to reduce these potential risks.

Coming now a bit more down to the engineering. I believe and I am strongly convinced, that there are at the end only a few questions which helps to find the right approach quite fast. Just try it and answer the following questions and you will see:

These are just a few questions and there are much more of them, like

but as mentioned above, try to answer them and you will see, you will find the right option for your specific situation quite fast and most important the arguments, why this is the right option.

Now let's come to an end. What are your thoughts? Feedback and/or comments are always welcome.

Learn more about SAP R&D/Engineering and Product Lifecycle Management capabilities and if you want to know more about identifying the right SAP solution within your organization, just contact us directly.

Which main dilemmas do I see?

Depending on the context, many different dilemmas can pop-up, but I think there are only a few which are always present:

Dilemma #1 – SAP is still seen as an ERP vendor

Still too many customers and prospects see SAP as a pure ERP vendor. This opinion is true, if they would life in 1990’s, but we have 30 years later and we talk about comprehensive end-to-end scenarios like “design-to-operate”, where the ERP is just a single and of course important piece of the puzzle, beside of many other products and solutions SAP is providing.

Dilemma #2 – The different ways of thinking

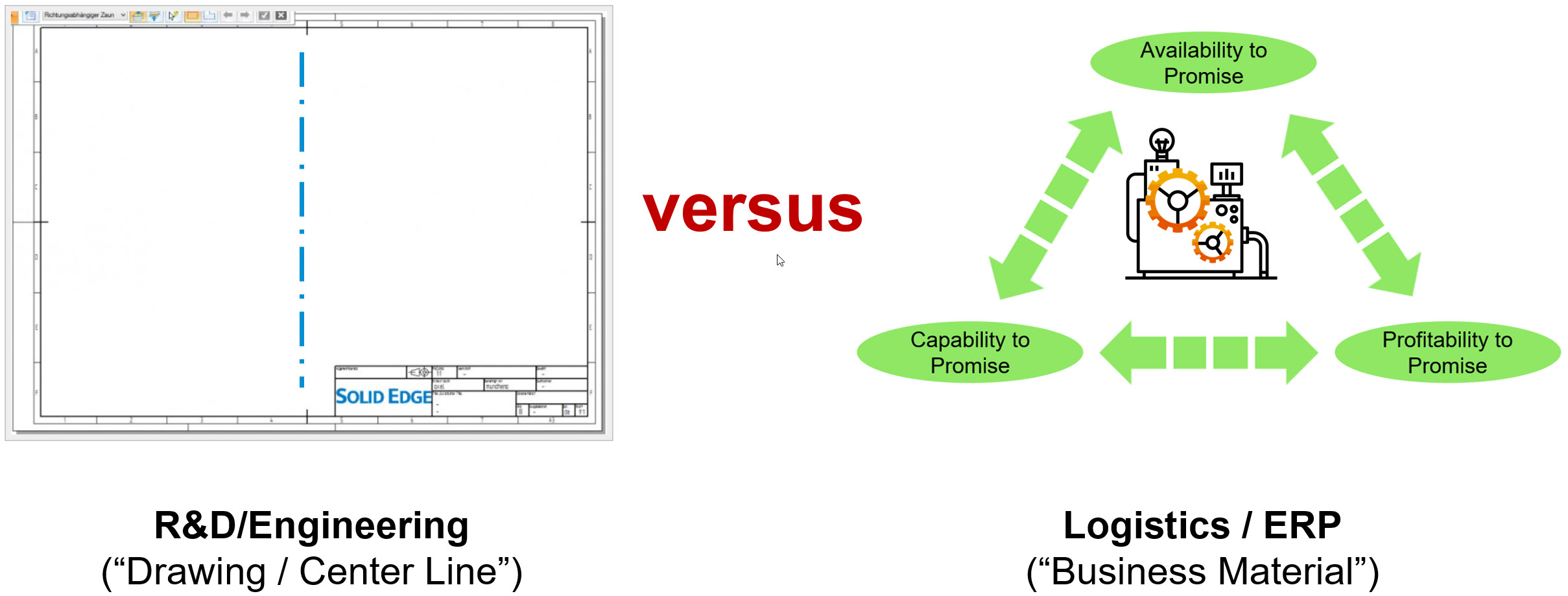

According to the customer organization, we mainly talk to buying centers, means to professionals seeing their specific needs and often not thinking cross company. As a young business consultant, I was engaged at KRONES. Mr. Islinger, one of the leading managers, brought the challenge on a simple page. “Either the starting point is the center line on a construction drawing or it is the business material”.

Picture 1 - The different way of thinking

Knowing that may the manual painted construction drawing is not any more the state of the art, it shows what the DNA of the different thinking is. And this is not about good or bad, because both is required at the same time, depending on the different end-to-end scenario flavors.

Dilemma #3 – Too many reasonable options

Finally, I see the different SAP provided reasonable options as a difficulty. To be honest, ask 10 experts and you will get 20 (somehow) different (and in their context correct) answers.

As an advising person, independent on customer, on partner, or on SAP side, we must provide the best solution for the appropriate customer situation and needs and not choices.

But how to come to this “best solution”?

How I explain it to customers, prospects, and colleagues

Find the right level of discussion

First, this kind of discussions cannot be done on high- or low-level, because the high-level does not provide the required insides to draw conclusions, whereas the low-level approach is too detailed and hinders fruitful conversations.

Secondly the high-level is often not enough industry related and therefore not as accurate as required by the customers and the “low”-level is too much product and technology related.

Picture 2 - The right level is there, where you get the right answers, based on a few questions

So, to find the “mid”-level is key. This is the level where customer specific and industry segment content becomes relevant.

But what contains this mid-level?

It must be …

- … industry segment and even subsegment specific.

- … cross value chain (do not loss the entire picture)

- … related to the industry specific strategic priorities (e.g. for Industrial Manufacturing)

- … peel out, what makes a customer special and successful

- … connecting the high-level with the low-level (to provide a seamless chain of arguments)

E2E Processes – Difference between customer order process types and logistical principles

Mentally distinguish between the customer order processes types and the logistical principles to fulfill the customer order. I talk here about the manufacturing industries, but this can be partly transferred to other industries as well. By the way something, I learnt from Prof. Dr. Jörg W. Fischer years ago.

Picture 3 - The four customer order process types and the four logistical principles in manufacturing industries

Think about, what is for your customer relevant and deviate the impact from an R&D/Engineering and Product Lifecycle Management (PLM) point of view. E.g. Configure-to-Order (CTO) means standardization, so how to standardize the product portfolio or Engineer-to-Order (ETO) is always heavily related to engineering change management?

It is of course a black and white illustration, and, in the reality, all types can be found at customer side at the same time, depending on their product and solution portfolio. Nevertheless, it helps to get to the point.

Start with the business side

For the sake of simplicity, I always start with the ERP system in the middle and then enhance it in the direction of engineering, production, and service according to the requirements.

The key question is, are the ERP system capabilities basically able, to serve the above-described customer order processing types and logistical principles in the specific customer situation?

The ERP system is for me like the glue, which holds everything together.

Picture 4 - Because every customer wants to sell something, the focus is on business administration

Next question is :

“What is triggering the processes in the ERP system?”

From a R&D/Engineering point of view, this is mainly the material. Basically, we need material masters and logistical bill of materials in the ERP system as a starting point. How can these material masters and logistical bill of material created in an automated manner?

Which capabilities are required from a Product Lifecycle Management point of view?

- Product Costing capabilities or

- Product compliance capabilities or

- system engineering capabilities or

- collaboration capabilities or

- …

The same question is going in the direction of production :

“What must be handed-over to production (plant specific logistical bill of material)?” and

”What is triggering the production (demand)? Only forecasts or as well customer- and project-driven demands?”

Process flow

And now, what makes the design-to-operate process complex? It is the overall process flow.

Picture 5 - Different type of customer order processing requires different value chains

For the Select-to-Order (SFS) and Configure-to-Order (CTO) processes, the process flow is always straight forward, from “left to right”. This means, from a product perspective, everything is defined, materials in the ERP systems are created, suppliers are identified, production engineering is done, and so on.

A bit more challenging is the Configure-to-Order PLUS (CTO+) and Engineer-to-Order (ETO) processes because the additional customer requirements lead in a for- and backward between engineering and production.

Whereas the SFS and CTO lead in a minor technical and commercial risk, the CTO+ and ETO scenario increasing this kind of risks, which of course leads in more sophisticated capabilities to mitigate these risks, which by the way is the reason, why more accurate financial and logistical capabilities are required to reduce these potential risks.

Try to answer mid-level questions

Coming now a bit more down to the engineering. I believe and I am strongly convinced, that there are at the end only a few questions which helps to find the right approach quite fast. Just try it and answer the following questions and you will see:

- Is there a corporate wide “IT Vendor”- and/or “PLM”-strategy? If yes, which one?

- Which is the main order process type and used logistical principle?

- Is there a production strategy (global (multi-plant) versus local (single-plant))?

- Which production type is predominating and how deep is the manufacturing penetration (Production assembly versus parts manufacturing or both at the same time)?

- How strong is the striving/pressure for standardization? It is just a kind of modularization, or does it go in the direction of systems engineering methodologies?

- What is more important? Seamless engineering domain integration or seamless logistical integration?

- Are there any engineering collaborations with internal and external stakeholders?

My conclusion and advice to you

These are just a few questions and there are much more of them, like

- number of engineering changes even during the order fulfillment or

- using of different currencies at the same time (multi-currencies),

- …

but as mentioned above, try to answer them and you will see, you will find the right option for your specific situation quite fast and most important the arguments, why this is the right option.

Now let's come to an end. What are your thoughts? Feedback and/or comments are always welcome.

Learn more about SAP R&D/Engineering and Product Lifecycle Management capabilities and if you want to know more about identifying the right SAP solution within your organization, just contact us directly.

Labels:

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

22 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

156 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- ISAE 3000 for SAP S/4HANA Cloud Public Edition - Evaluation of the Authorization Role Concept in Enterprise Resource Planning Blogs by SAP

- SAP GTS classification not recorded at compliance document creation in Enterprise Resource Planning Q&A

- Credit Release Reason pop up in VKM1 in Enterprise Resource Planning Q&A

- Your feedback helps to improve SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- the purchasing group extract reason details not appearing mm03 in sap? in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 8 | |

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |