- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- Condition-Based Maintenance in SAP S/4HANA Cloud 2...

Product Lifecycle Management Blogs by SAP

Dive into product lifecycle management news, learn about digitalizing PLM for the digital supply chain, and stay informed with product updates from SAP.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-15-2022

1:40 PM

This blog post provides an overview of Condition-Based Maintenance feature available in SAP S/4HANA Cloud 2202 for Asset Management

Continuously monitoring the health of an equipment and taking steps to avoid a malfunction or a breakdown helps to reduce the impact on production and safeguards the environmental and work health needs of an organization.

With SAP S/4HANA Cloud 2202, Maintenance Management provides a lightweight “Condition-Based Maintenance” capability. It allows you to define conditions (limits and tolerance values) and corresponding actions to be taken when such conditions are breached.

Condition-based maintenance means that based on the condition of the asset, a maintenance activity is executed. The end goal is to listen to the various parameters of an equipment and catch the anomaly before it leads to the failure of a machine. The condition of an asset is determined by how efficiently it is performing and fulfilling its purpose. The function of an equipment can be influenced by various factors, some of which are inherent to the equipment (such as sensors, operating conditions, operating hours, and so on) and some that are beyond human control (environmental, geo-political, and so on).

In simple terms, condition-based maintenance means that if a measurement reading crosses a limit, it triggers an activity that will bring the parameter back within limits. But, a simple “greater than or lesser than” condition is not sufficient in some situations. You need additional control over when a notification should be created and what should be the priority of such a notification.

Take the example of a centrifugal pump that, as defined by the OEM, under optimal conditions can have a throughput of 100 liters/hour. The equipment can still be operated till 112 liters/hour (beyond which the outflow control valves may get damaged) or as low as 90 liters/hour (beyond which the functionality of a dependent system in the process may be impacted).

However, you might not want to wait till the measurement crosses these limits. You may want to react as soon as the reading crosses 105 liters/hour (or 95 liters/hour on the lower side). This additional level of control is possible by defining a tolerance band above and below the target reading. With this possibility, you can choose to say what you wish to do under any of the four conditions:

The main screen of the Create Measuring Point has been enhanced with an additional section where, against each condition, you can maintain the following:

For example, if the characteristic for a measuring point is called Operating_Temperature and the unit of measure of the characteristic is degree (C), then you will see a message informing you that the temperature has crossed the limits.

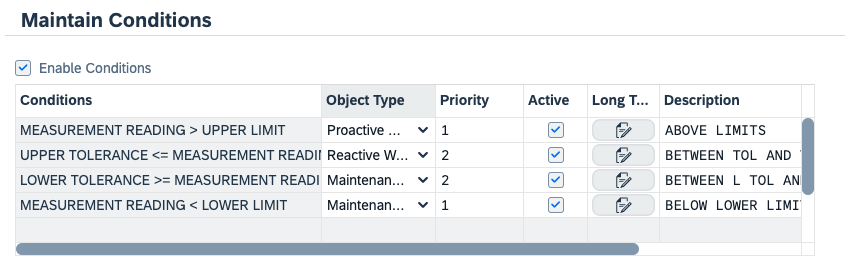

If you do not wish to execute a specific condition (temporarily), you can choose to deactivate that condition. You may also deactivate all the conditions for that measuring point by disabling all the conditions in the table (Enable Conditions checkbox). Please check the customizing section below .

The Additional Data screen of Create Measuring Point app has been enhanced to include the possibility to maintain two additional levels of tolerances relative to the target reading. The upper and lower measurement tolerances can be either relative to the target reading (%) or an absolute reading (same UoM as the measuring point characteristic).

A condition set as shown below can be modelled on the measuring point:

Application to be used for Measuring Point creation : https://fioriappslibrary.hana.ondemand.com/sap/fix/externalViewer/#/detail/Apps('EAMS_LPD_MP_IK01')/...

The following graphic represents the key terms used in condition-based maintenance and how they come together to help a maintenance supervisor or planner understand why a maintenance notification was created.

As per the configuration maintained above (also depicted by the graphic), when the measurement reading is between 100 and 105, maintenance notifications will not be created. When the measurement reading is between 105 and 112, a high priority maintenance notification will be created, and when the measurement reading is more than 112 (or less than 90) a very high priority maintenance notification will be created.

Application to be used for Measuring Document creation: https://fioriappslibrary.hana.ondemand.com/sap/fix/externalViewer/#/detail/Apps('IK11')/S27

For the condition-based maintenance functionality to work, the following prerequisites must be met:

The concept of 9-phase model for Reactive Maintenance was introduced with SAP S/4HANA Cloud 2011 by Maintenance Management. Please check this blog post to understand this process better.

When a condition is defined such that the result of the condition leads to the creation of Y1 (Maintenance Request), the maintenance request follows the pre-defined phase model approach. This means that the maintenance request that is created as a result of a measurement reading will still need to be approved by a maintenance supervisor and then taken forward through planning, approval, preparation, scheduling and all the way to execution and post execution.

There may be situations where you may want to have a bit more control on the condition evaluation itself. For example, multiple identical measurement readings have been reported and you do not want to create a maintenance notification for each of those readings. Such situations can be handled through custom logic through the Cloud BAdI Condition Evaluation for Notification Creation (BADI_MSMT_DOC_CNDN_EVALUATION) within the business context EAMS: Measurement Document (EAMS_MDOC). This capability is delivered with SAP S/4HANA Cloud 2202 . For more details about the usage of this BAdI, see here.

While the current feature is available as a GUI for HTML application only in SAP S/4HANA Cloud (and not in SAP S/4HANA), we do have plans to deliver a more intuitive and insightful Fiori-based report for managing measuring points in the future.

In this blog post we could learn the feature of automatic Maintenance Notification creation based upon the entered measurement reading crossing the threshold values which are the predefined in the measuring point.

Please feel free to ask any questions or if you have any feedback to provide.

(This blog post has been created in collaboration with niranjan.raju).

Continuously monitoring the health of an equipment and taking steps to avoid a malfunction or a breakdown helps to reduce the impact on production and safeguards the environmental and work health needs of an organization.

With SAP S/4HANA Cloud 2202, Maintenance Management provides a lightweight “Condition-Based Maintenance” capability. It allows you to define conditions (limits and tolerance values) and corresponding actions to be taken when such conditions are breached.

Condition-based maintenance means that based on the condition of the asset, a maintenance activity is executed. The end goal is to listen to the various parameters of an equipment and catch the anomaly before it leads to the failure of a machine. The condition of an asset is determined by how efficiently it is performing and fulfilling its purpose. The function of an equipment can be influenced by various factors, some of which are inherent to the equipment (such as sensors, operating conditions, operating hours, and so on) and some that are beyond human control (environmental, geo-political, and so on).

In simple terms, condition-based maintenance means that if a measurement reading crosses a limit, it triggers an activity that will bring the parameter back within limits. But, a simple “greater than or lesser than” condition is not sufficient in some situations. You need additional control over when a notification should be created and what should be the priority of such a notification.

Define Conditions for Measuring Points

Take the example of a centrifugal pump that, as defined by the OEM, under optimal conditions can have a throughput of 100 liters/hour. The equipment can still be operated till 112 liters/hour (beyond which the outflow control valves may get damaged) or as low as 90 liters/hour (beyond which the functionality of a dependent system in the process may be impacted).

However, you might not want to wait till the measurement crosses these limits. You may want to react as soon as the reading crosses 105 liters/hour (or 95 liters/hour on the lower side). This additional level of control is possible by defining a tolerance band above and below the target reading. With this possibility, you can choose to say what you wish to do under any of the four conditions:

- When the measurement reading crosses the upper limit

- When the measurement reading is between the upper tolerance and upper limit (as a % of target)

- When the measurement reading is between the lower tolerance and lower limit (as a % of target)

- When the reading is below the lower limit

The main screen of the Create Measuring Point has been enhanced with an additional section where, against each condition, you can maintain the following:

- The type of maintenance notification that should be created when the measurement reading falls within that range

- The priority of the maintenance notification

- Default description and long text for the notification. If no description is maintained, the system generates a notification with default description informing you that the values have crossed the limits.

For example, if the characteristic for a measuring point is called Operating_Temperature and the unit of measure of the characteristic is degree (C), then you will see a message informing you that the temperature has crossed the limits.

If you do not wish to execute a specific condition (temporarily), you can choose to deactivate that condition. You may also deactivate all the conditions for that measuring point by disabling all the conditions in the table (Enable Conditions checkbox). Please check the customizing section below .

Limits and Tolerances

The Additional Data screen of Create Measuring Point app has been enhanced to include the possibility to maintain two additional levels of tolerances relative to the target reading. The upper and lower measurement tolerances can be either relative to the target reading (%) or an absolute reading (same UoM as the measuring point characteristic).

A condition set as shown below can be modelled on the measuring point:

- Target: 100 liters/hour

- Upper Limit: 112 liters/hour

- Lower Limit: 90 liters/hour

- Upper Tolerance: 5% (translates to 105 liters/hour as upper tolerance)

- Lower Tolerance: 5% (translates to 95 liters/hour as lower tolerance)

Application to be used for Measuring Point creation : https://fioriappslibrary.hana.ondemand.com/sap/fix/externalViewer/#/detail/Apps('EAMS_LPD_MP_IK01')/...

The following graphic represents the key terms used in condition-based maintenance and how they come together to help a maintenance supervisor or planner understand why a maintenance notification was created.

As per the configuration maintained above (also depicted by the graphic), when the measurement reading is between 100 and 105, maintenance notifications will not be created. When the measurement reading is between 105 and 112, a high priority maintenance notification will be created, and when the measurement reading is more than 112 (or less than 90) a very high priority maintenance notification will be created.

Application to be used for Measuring Document creation: https://fioriappslibrary.hana.ondemand.com/sap/fix/externalViewer/#/detail/Apps('IK11')/S27

Customizing

For the condition-based maintenance functionality to work, the following prerequisites must be met:

- The Conditions table in the main screen of the Create Measuring Point app will be enabled for maintaining values only if the message for a measurement range is either set as empty or Warning (W). If the value is maintained as error (E), the option to maintain conditions is disabled.

- The configuration activity Define Measuring Point Categories has now been enhanced with a checkbox Create Notification. This checkbox must be selected if you wish to trigger notifications when the measurement readings for this measuring point cross the limits or tolerances. If this checkbox is not selected, then the Enable Conditions section in the Create Measuring Point app will appear disabled.

How does the 9-phase Maintenance Process Work?

The concept of 9-phase model for Reactive Maintenance was introduced with SAP S/4HANA Cloud 2011 by Maintenance Management. Please check this blog post to understand this process better.

When a condition is defined such that the result of the condition leads to the creation of Y1 (Maintenance Request), the maintenance request follows the pre-defined phase model approach. This means that the maintenance request that is created as a result of a measurement reading will still need to be approved by a maintenance supervisor and then taken forward through planning, approval, preparation, scheduling and all the way to execution and post execution.

Extensibility

There may be situations where you may want to have a bit more control on the condition evaluation itself. For example, multiple identical measurement readings have been reported and you do not want to create a maintenance notification for each of those readings. Such situations can be handled through custom logic through the Cloud BAdI Condition Evaluation for Notification Creation (BADI_MSMT_DOC_CNDN_EVALUATION) within the business context EAMS: Measurement Document (EAMS_MDOC). This capability is delivered with SAP S/4HANA Cloud 2202 . For more details about the usage of this BAdI, see here.

Future Road Map

While the current feature is available as a GUI for HTML application only in SAP S/4HANA Cloud (and not in SAP S/4HANA), we do have plans to deliver a more intuitive and insightful Fiori-based report for managing measuring points in the future.

In this blog post we could learn the feature of automatic Maintenance Notification creation based upon the entered measurement reading crossing the threshold values which are the predefined in the measuring point.

Please feel free to ask any questions or if you have any feedback to provide.

(This blog post has been created in collaboration with niranjan.raju).

Labels:

20 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- Transition from SAP Solution Manager to SAP Cloud ALM with help from SAP Enterprise Support in Product Lifecycle Management Q&A

- What is overall equipment effectiveness in Product Lifecycle Management Q&A

- What are the advantages & disadvantages of making an equipment as Functional location in SAP PM in Product Lifecycle Management Q&A

- SAP Crystal Reports, developer version for Microsoft Visual Studio in Product Lifecycle Management Q&A

- Interview questions & interview preparation tips for SAP plant maintenance module. in Product Lifecycle Management Q&A