- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Task Interleaving in SAP EWM

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

krishnakumar_ch

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-13-2022

5:48 AM

Introduction:

In this blog post you will learn about the task interleaving in SAP EWM. Task interleaving helps to cut down the unnecessary movements and enables better optimization of unutilized resources leading to reduction of travel time and improving operational efficiency.

For example, during an inbound process, once the goods are dropped to the respective storage type, a warehouse order will be assigned automatically to the same resource for picking up goods from the same /nearest storage type. This helps in better utilization of the resources.

Solution Approach:

The below mentioned configuration steps can be employed to achieve this functionality:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Resource Types.

If required assign bin access types and hu type groups by selecting the respective options.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queue Types.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queues.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queues=>Define Queue Determination Criteria.

Testing:

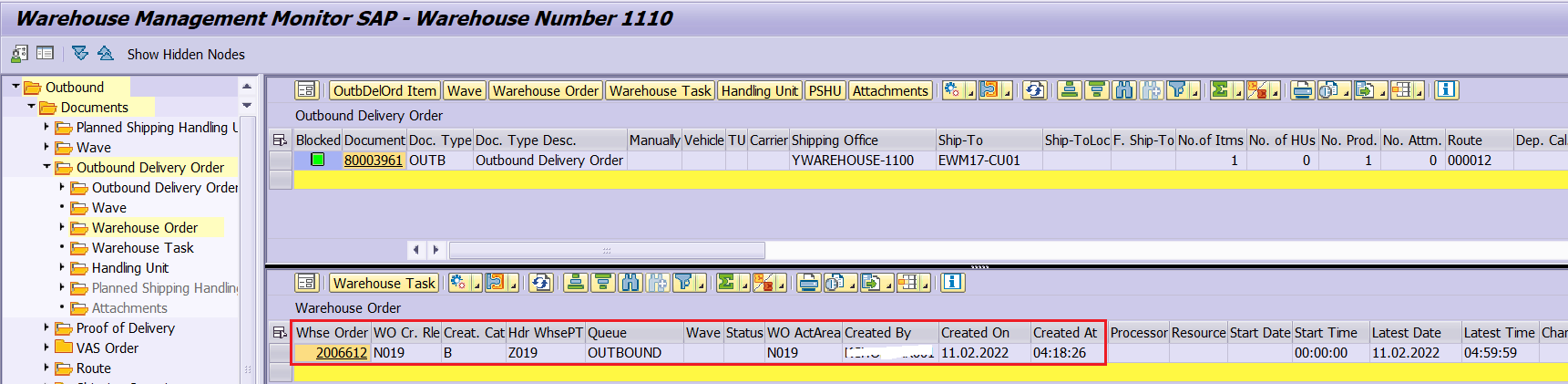

Outbound delivery: 80003961

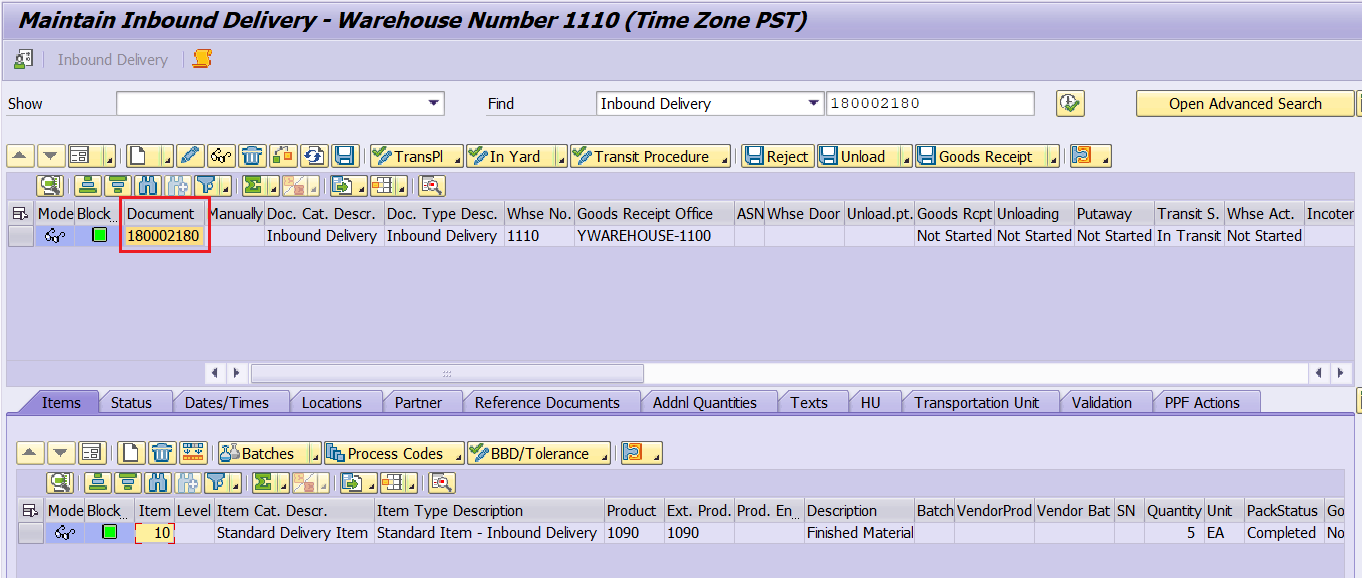

Inbound delivery: 180002180

First create a warehouse task for an outbound delivery using the t-code: /SCWM/TODLV_O.

Then create a warehouse task for an inbound delivery using the t-code: /SCWM/TODLV_I.

Warehouse order is created for an outbound delivery and it is assigned to the respective queue: OUTBOUND.

Similarly warehouse order is created for an inbound delivery and it is assigned to the right queue: INBOUND.

As per queue type sequencing, system should propose the INBOUND queue first and then OUTBOUND queue, so that a product will be dropped to the storage type: N019 for put-away & other product will be picked for an outbound delivery from the same or nearby storage type.

Scanning the HU from Goods Receipt zone

Scanning the destination bin to perform the put away.

Next an outbound delivery warehouse order is proposed automatically to perform the picking activity. Scan the source/destination bin, product, and quantity.

Conclusion:

This blog post walks you through various steps involved in Task interleaving with test results. As per the queue type sequencing INBOUND queue is assigned first and then OUTBOUND queue.Hence its results are verified by executing the above test scenario.

In this blog post you will learn about the task interleaving in SAP EWM. Task interleaving helps to cut down the unnecessary movements and enables better optimization of unutilized resources leading to reduction of travel time and improving operational efficiency.

For example, during an inbound process, once the goods are dropped to the respective storage type, a warehouse order will be assigned automatically to the same resource for picking up goods from the same /nearest storage type. This helps in better utilization of the resources.

Solution Approach:

The below mentioned configuration steps can be employed to achieve this functionality:

- Create a Resource Types using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Resource Types.

If required assign bin access types and hu type groups by selecting the respective options.

- Define queue types using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queue Types.

- Define queue by assigning the queue type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queues.

- Define queue determination criteria using the below mentioned node, so that queue will be assigned automatically once the warehouse task is created.

- In this case the put-away warehouse process type is: N019 and picking warehouse process type is: Z019.

- Both the put-away and picking storage type activity area is N019.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Resource Management->Define Queues=>Define Queue Determination Criteria.

- Define Resource Group using the t-code:/SCWM/RGRP.

- Maintain queue type sequencing using the t-code:/SCWM/QTSQ.

- Maintain queue sequence for resource group using the t-code: /SCWM/QSEQ.

- Create resource using the t-code:/SCWM/RSRC.

- Maintain user by assigning the resource using the t-code:/SCWM/USER.

Testing:

- Created outbound & inbound delivery to perform this testing.

Outbound delivery: 80003961

Inbound delivery: 180002180

- In the delivery screen, create warehouse order/task for both outbound & inbound delivery, manually by clicking on CREATE button and then SAVE.

First create a warehouse task for an outbound delivery using the t-code: /SCWM/TODLV_O.

Then create a warehouse task for an inbound delivery using the t-code: /SCWM/TODLV_I.

- Warehouse order/task can be viewed in the monitor screen using the transaction code:/SCWM/MON.

Warehouse order is created for an outbound delivery and it is assigned to the respective queue: OUTBOUND.

Similarly warehouse order is created for an inbound delivery and it is assigned to the right queue: INBOUND.

- Login to the RF by mentioning the warehouse number and resource using the t-code:/SCWM/RFUI, then follow the path System-Guided->System-guided Selection.

As per queue type sequencing, system should propose the INBOUND queue first and then OUTBOUND queue, so that a product will be dropped to the storage type: N019 for put-away & other product will be picked for an outbound delivery from the same or nearby storage type.

Scanning the HU from Goods Receipt zone

Scanning the destination bin to perform the put away.

Next an outbound delivery warehouse order is proposed automatically to perform the picking activity. Scan the source/destination bin, product, and quantity.

Conclusion:

This blog post walks you through various steps involved in Task interleaving with test results. As per the queue type sequencing INBOUND queue is assigned first and then OUTBOUND queue.Hence its results are verified by executing the above test scenario.

17 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- Error Full-HU needs a post-HU in Supply Chain Management Q&A

- /scwm/adgi - Post GI - API or FM in Supply Chain Management Q&A

- SAP DM - Master Data Management in Supply Chain Management Q&A

- Freight Generation in Data Collation Document using Freight Rate Table or Pricing Multireference in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |