- SAP Community

- Products and Technology

- CRM and Customer Experience

- CRM and CX Blogs by Members

- Delivery Scheduling in SAP Sale Order

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Delivery Scheduling in OTC [Order to Cash Process] is a Process of Determining Delivery Dates and Confirm Quantities for each Material/Line Item in a specific Sale Order.

SAP has the standard parameters to Determine it into the Sale Order…

| A | Pick Pack Time |

| B | Loading Time |

| C | Replenishment Lead Time [RLT] |

| D | Transportation Lead Time [TLT] |

| E | Transit Time |

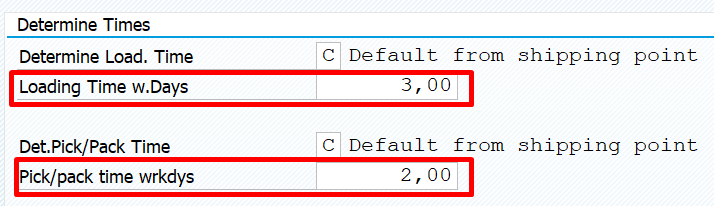

1. Pick Pack Time:

- It is the time taken to pick the Material from Storage Location and to Pack it

- We maintain it in Shipping Point.

Path:

SPRO-->IMG Activity-->Enterprise Structure-->Definition-->Logistics Execution-->Define Copy, Delete, Check Shipping Point-->Define Shipping Point

2. Loading Time:

-It is the time taken to do the process of Loading the Goods in to the Vehicle

-We maintain it in Shipping Point.

3. Replenishment Lead Time [R.L.T]:

- It is the Time taken to do the Process of manufacturing of Goods and make it ready for Dispatch.

- We maintain R.L.T in Material Master/ M.R.P View 3 tab

- In Delivery Scheduling, System Consider R.L.T only if the stock is not available

4. Transportation Lead Time [T.L.T]:

- It is the Time taken to arrange the Vehicle for Dispatching the Goods to Customer

- We maintain T.L.T in Route

5. Transit Time:

- It is the Time taken to deliver the Goods from Plant to Customer [Travelling Time]

- We maintain Transit Time in Route

- System will consider the working days in calendar while performing Delivery Scheduling

- System considers the Calendar from from the below sources.

| Shipping Point |

| Plant |

| Sales Org |

| Customer |

TABLE about the Checks for each Scenario

| Pick/Pack Time | Loading Time | Replenishment Lead Time [RLT] | Check W/O RLT [Tcode-OVZ9] | Transportation Lead Time | Transit Time | Complete Delivery by Law | Sale Order Quantity | Material Available Stock | Confirmed Quantity | Sale Order Date | Customer Requested Delivery Date | Backward Schedule Status | Forward Schedule Status | |

| Scenario - 1 | YES | YES | Not Relevant | Not Relevant | NO | NO | NO | 10 | 100 | 10 | 17.09.2021 | 18.09.2021 | Fail | Success |

| Scenario - 2 | YES | YES | Not Relevant | Not Relevant | NO | NO | NO | 50 | 100 | 50 | 18.09.2021 | 25.09.2021 | Success | #NA |

| Scenario - 3 | YES | YES | YES | Uncheck | NO | NO | NO | 50 | 0 | 50 | 18.09.2021 | 25.09.2021 | Fail | Success |

| Scenario - 4 | YES | YES | YES | Uncheck | NO | NO | NO | 50 | 0 | 50 | 18.09.2021 | 03.10.2021 | Success | #NA |

| Scenario - 5 | YES | YES | YES | Uncheck | NO | NO | NO | 150 | 100 | 100+50 | 19.09.2021 | 28.09.2021 | Success | Success |

| Scenario - 6 | YES | YES | YES | Uncheck | NO | NO | NO | 150 | 100 | 150 | 19.09.2021 | 10.10.2021 | Success | #NA |

| Scenario – 7 | YES | YES | YES | Uncheck | NO | NO | NO | 150 | 100 | 100+50 | 19.09.2021 | 22.09.2021 | Fail | Success |

| Scenario – 8 | YES | YES | YES | Uncheck | NO | NO | YES | 150 | 100 | 150 | 19.09.2021 | 22.09.2021 | Fail | Success |

| Scenario – 9 | YES | YES | YES | Uncheck | NO | NO | YES | 150 | 100 | 150 | 19.09.2021 | 05.10.2021 | Success | #NA |

| Scenario – 10 | YES | YES | NO [No Scope for producing the goods] | Check | NO | NO | NO | 150 | 100 | 100 | 19.09.2021 | 28.10.2021 | Success | #NA |

| Scenario – 11 | YES | YES | NO [No Scope for producing the goods] | Check | NO | NO | NO | 150 | 100 | 100 | 22.09.2021 | 25.10.2021 | Fail | Success |

| Scenario – 12 | YES | YES | NO [No Scope for producing the goods] | Check | NO | NO | NO | 150 | 0 | 100 | 21.12.2021 | 21.01.2022 | Fail | Not Relevant |

| Scenario – 13 | YES | YES | YES | Uncheck | YES | YES | NO | 60 | 100 | 60 | 24.09.2021 | 07.10.2021 | Fail | Success |

| Scenario – 14 | YES | YES | YES | Uncheck | YES | YES | NO | 60 | 100 | 60 | 24.09.2021 | 13.10.2021 | Success | #NA |

| Scenario – 15 | YES | YES | YES | Uncheck | YES | YES | NO | 60 | 0 | 60 | 26.12.2021 | 11.01.2022 | Fail | Success |

| Scenario – 16 | YES | YES | YES | Uncheck | YES | YES | NO | 60 | 0 | 60 | 26.12.2021 | 24.01.2022 | Success | #NA |

Process Of Delivery Scheduling

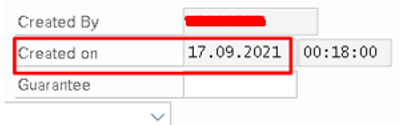

Scenario – 1

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines.

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines.

2. In this case, system ignored RLT because, full stock is available in the Plant.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | ||||||||

3. Sale Order Creation Date | |||||||||

4. Backward Delivery Scheduling Fails As To be Sale Order date [13.09.2021] is beyond today’s date, Backward Scheduling Fails [Sales Order Quantity is not Confirmed] | |||||||||

5. Backward Delivery Scheduling Process

| |||||||||

6. Forward Delivery Scheduling Success Forward Scheduling is determined based on Current Sale Order date + Pick pack days + Loading days [Sales Order Quantity Confirmed]

| |||||||||

7. Forward Delivery Scheduling Process In this scenario, Delivery Creation date – 20.09.2021 P.G.I date – 22.09.2021

| |||||||||

Scenario 1 of 16

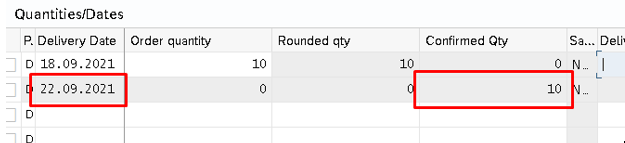

NOTE: 1. When Backward Scheduling Success, system determines single Schedule line.

- In this case, system ignored RLT because, full stock is available in the Plant.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | ||||||||

3. Sale Order Creation Date

| |||||||||

4. Backward Delivery Scheduling Fails As To be Sale Order date creation date [20.09.2021] is after today’s date [18.09.2021], Backward Scheduling success [Sales Order Quantity Confirmed]

| |||||||||

5. Backward Delivery Scheduling Process In this scenario, Delivery Creation date – 20.09.2021 P.G.I date – 25.09.2021

| |||||||||

Scenario 2 of 16

Note: 1. When Backward Scheduling fails, system determines two Schedule lines.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

1. Customer Requested Delivery Date | 2. Pick Pack and Loading Time | ||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | ||||||||||

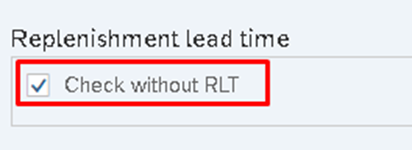

| 5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | |||||||||||

6. Backward Delivery Scheduling Fails As To be Sale Order date creation date [10.09.2021] is beyond today’s date [18.09.2021], Backward Scheduling Fails [Sales Order Quantity Not Confirmed] | |||||||||||

7. Backward Delivery Scheduling Process

| |||||||||||

8. Forward Delivery Scheduling Success Forward Scheduling is determined based on Current Sale Order date + Pick pack days + Loading days + R.L.T days [Sales Order Quantity Confirmed] | |||||||||||

9. Forward Delivery Scheduling Process In this scenario, System considers R.L.T – 10 days, as the Material stock is not available. Delivery Creation date – 28.09.2021 P.G.I date – 03.10.2021

| |||||||||||

Scenario 3 of 16

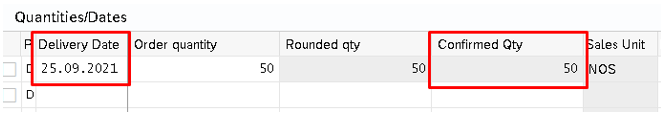

NOTE: 1. When Backward Scheduling Success, system determines single Schedule line.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

| 1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View

| |||||||||||

5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | ||||||||||||

| 6. Backward Delivery Scheduling Success

| ||||||||||||

7. Backward Delivery Scheduling Process In this scenario, System considers R.L.T - 10 days, as the Material stock is not available still the Customer Requested Delivery date is met. Delivery Creation date – 28.09.2021 P.G.I date – 03.10.2021

| ||||||||||||

Scenario 4 of 16

NOTE: 1. In this scenario, Backward Scheduling Success for partial quantity and Forward Scheduling success for the rest partial quantity, so system determines Two single Schedule line.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

1. Customer Requested Delivery Date | 2. Pick Pack and Loading Time | ||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | ||||||||||

| 5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | |||||||||||

6. Backward Scheduling Partially Success In this scenario the Customer Requested Delivery date is met for 100 Quantity and for the rest 50 qty Backward Scheduling is fail. | |||||||||||

7. Backward Delivery Scheduling Process In this Scenario, Delivery Creation date – 23.09.2021 P.G.I date – 28.09.2021 for 100 quantity

| |||||||||||

8. Forward Delivery Scheduling Success For 50 qty Forward Scheduling is Pass.

| |||||||||||

9. Forward Delivery Scheduling Process In this scenario system considers R.L.T - 10 days, as the Material stock is not available for 50 qty. And Delivery Creation date – 29.09.2021 P.G.I date – 04.10.2021

| |||||||||||

Scenario 5 of 16

NOTE: 1. When Backward Scheduling Success, system determines single Schedule line.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

| 1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View

| |||||||||||

5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | ||||||||||||

| 6. Backward Delivery Scheduling Success In this scenario the Customer Requested Delivery date is met for total 150 Quantity, so Backward Scheduling Success. | ||||||||||||

7. Backward Delivery Scheduling Process And Delivery Creation date – 05.10.2021 P.G.I date – 10.10.2021

| ||||||||||||

Scenario 6 of 16

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines, but in this scenario, System determines 3 Schedule lines due to stock availability.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

1. Customer Requested Delivery Date | 2. Pick Pack and Loading Time | ||||||||||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | ||||||||||||||||||

| 5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | |||||||||||||||||||

6. Backward Delivery Scheduling Fails In this scenario the Customer Requested Delivery date not met for total 150 Quantity, so Backward Scheduling Fails.

| |||||||||||||||||||

7. Backward Delivery Scheduling Process

| |||||||||||||||||||

8. Forward Delivery Scheduling Success Forward Scheduling is Success, for 100 and 50 qty there will be different Confirmation dates as based on Material stock availability.

| |||||||||||||||||||

9. Forward Delivery Scheduling Process For 100 Qty Delivery Creation date for 100 qty – 19.09.2021 P.G.I date – 24.09.2021

For 50 Qty Delivery Creation date for 50 qty – 29.09.2021 P.G.I date – 04.10.2021

| |||||||||||||||||||

Scenario 7 of 16

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

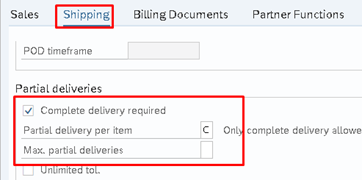

- In this scenario, the Customer requirement is to get the Complete requirement in single Delivery which is maintained in Customer Master->Sales Area data->Shipping tab.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | |||||||||||

5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked

| 6. Complete Delivery Required by Law in Customer Master/Sales Area data | |||||||||||

7. Backward Delivery Scheduling Fails In this scenario the Customer Requested Delivery date not met for total 150 Quantity, so Backward Scheduling Fails.

| ||||||||||||

8. Backward Delivery Scheduling Process

| ||||||||||||

9. Forward Delivery Scheduling Success Forward Scheduling is Success for 150 qty at a time, not partial delivery allowed as per Customer requirement, so the total quantity is confirmed at a time.  | ||||||||||||

10. Forward Delivery Scheduling Process For 100 Qty Delivery Creation date for150 qty – 29.09.2021 P.G.I date – 04.10.2021

| ||||||||||||

Scenario 8 of 16

NOTE: 1. When Backward Scheduling Success, system determines single Schedule line.

- Replenishment Lead Time [R.L.T] is, Approximate Number of days to be considered for producing the stock of the specific Material, which would be maintained in Material MasteràMRP3 View.

- In this scenario, the Customer requirement is to get the Complete requirement in single Delivery which is maintained in Customer Master->Sales Area data->Shipping tab.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | |||||||||||

| 5. Availability Check Control For not to consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked | 6. Complete Delivery Required by Law in Customer Master/Sales Area data | |||||||||||

7. Backward Delivery Scheduling Success In this scenario the Customer Requested Delivery date met for total 150 Quantity, so Backward Scheduling Success.

| ||||||||||||

8. Backward Delivery Scheduling Process Delivery Creation date for150 qty – 29.09.2021 P.G.I date – 05.10.2021

| ||||||||||||

Scenario 9 of 16

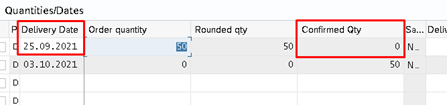

NOTE: 1. When Backward Scheduling Success, system determines single Schedule line.

- Check Without RLT is Checked, so system should not consider the number of days for producing the stock from Material Master.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | |||||||||

5. Availability Check Control To consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be checked | ||||||||||

6. Backward Scheduling Partially Fail and Partially Success: In this scenario the Customer Requested Delivery date met only for 100 Quantity, and ‘Check Without R.L.T’ is checked so system did not consider the Production plan, so it did not confirm the rest 50 quantity and Backward Scheduling Success for 100 qty and fails for 50 qty.

| ||||||||||

7. Backward Delivery Scheduling Process Delivery Creation date for 100 qty – 23.09.2021 P.G.I date – 28.09.2021

| ||||||||||

Scenario 10 of 16

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines.

- Check Without RLT is Checked, so system should not consider the number of days for producing the stock from Material Master.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View

| |||||||||

5. Availability Check Control To consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be checked

| ||||||||||

6. Backward Delivery Scheduling Fails In this scenario the Customer Requested Delivery date not met so Backward Scheduling Fails.

| ||||||||||

7. Backward Delivery Scheduling Process

| ||||||||||

8. Forward Delivery Scheduling Success Forward Scheduling is Success for 100 qty and as RLT is checked, system would not consider the time for Production Planning and that’s why 50 qty is neither confirmed nor shown in the system. | ||||||||||

9. Forward Delivery Scheduling Process For 100 Qty Delivery Creation date for100 qty – 22.09.2021 P.G.I date – 27.10.2021

| ||||||||||

Scenario 11 of 16

NOTE: 1. When Backward Scheduling fails, system determines two Schedule lines.

- Check Without RLT is Checked, so system should not consider the number of days for producing the stock from Material Master.

- And as a result, NO Stock is available and RLT is checked, so system not confirmed the Quantity.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | |

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View | |

| 5. Availability Check Control To consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be checked | ||

6. Backward Delivery Scheduling Fails In this scenario the Customer Requested Delivery date not met for 150 Quantity so Backward Scheduling Fails, and R.L.T is checked so system did not consider the Production plan, so it did not confirm the rest 150 quantity.

| ||

7. Backward Delivery Scheduling Process There is no process of Backward or Forward Scheduling, as there is no scope for waiting period to be considered for this specific order to be processed and delivered, it is the Customer Requirement. | ||

Scenario 12 of 16

Note: 1. When Backward Scheduling fails, system determines two Schedule lines.

- If we have Transportation Lead Time [T.L.T] and Pick Pack Time [P/P time] and Stock is available then system considers T.L.T or P/P time whichever is higher.

- Instead of 08.10.2021 system proposes Customer Goods Receiving date as 09.10.2021, is because on 02.10.2021 the respective Calendar states the Holiday.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | ||||||||||

3. Sale Order Creation Date

| |||||||||||

4. Backward Delivery Scheduling Fails In this scenario the Customer Requested Delivery date not met for 60 Quantity so Backward Scheduling Fails because system considers, Transportation Lead Time [7 days] + Loading Time [2 days] + Transit Time [5 days]

| |||||||||||

5. Backward Delivery Scheduling Process

| |||||||||||

6. Forward Delivery Scheduling Success Forward Scheduling is Success for 60 qty.

| |||||||||||

7. Forward Delivery Scheduling Process Delivery Creation date for 60 qty – 24.09.2021 P.G.I date – 03.10.2021 Customer Goods Receiving date – 09.10.2021

| |||||||||||

Scenario 13 of 16

Note: 1. When Backward Scheduling Success, system determines single Schedule line.

- If we have Transportation Lead Time [T.L.T] and Pick Pack Time [P/P time] and Stock is available then system considers T.L.T or P/P time whichever is higher.

- Instead of 08.10.2021 system proposes Customer Goods Receiving date as 09.10.2021, is because on 02.10.2021 the respective Calendar states the Holiday.

1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time | ||||||||||

3. Sale Order Creation Date

| |||||||||||

4. Backward Delivery Scheduling Success In this scenario the Customer Requested Delivery date met for 60 Quantity so Backward Scheduling Success.

| |||||||||||

5. Backward Delivery Scheduling Process Delivery Creation date for 60 qty – 30.09.2021 P.G.I date – 08.10.2021 Customer Goods Receiving date – 13.10.2021

| |||||||||||

Scenario 14 of 16

Note: 1. When Backward Scheduling fails, system determines two Schedule lines.

- If we have Transportation Lead Time [T.L.T] and Pick Pack Time [P/P time] and Stock is available then system considers T.L.T or P/P time whichever is higher.

Ex: If we have,

Transportation Lead Time [T.L.T] – 7 days

Pick Pack Time [P/P Time] – 3 days

Replenishment Lead Time [R.L.T] – 10 days and

Stock is Not Available then system considers R.L.T + P/P time or T.L.T whichever is higher.

| 1. Customer Requested Delivery Date | 2. Pick Pack – Loading Time

| |||||||||||||

3. Sale Order Creation Date | 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View

| |||||||||||||

5. Availability Check Control To consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked

| ||||||||||||||

| 6. Backward Delivery Scheduling Fails

| ||||||||||||||

7. Backward Delivery Scheduling Process Proposed SO creation date going beyond today’s date so Backward Scheduling Fails

| ||||||||||||||

8. Forward Delivery Scheduling Success Forward Scheduling is Success for 60 qty.  | ||||||||||||||

9. Forward Delivery Scheduling Process And Delivery Creation date for 60 qty – 24.09.2021 P.G.I date – 03.10.2021 Customer Goods Receiving date – 09.10.2021 Note: Instead of 08.10.2021 system proposes Customer Goods Receiving date as 09.10.2021, is because on 02.10.2021 the respective Calendar states the Holiday.

| ||||||||||||||

Scenario 15 of 16

Note: 1. When Backward Scheduling fails, system determines two Schedule lines.

- If we have Transportation Lead Time [T.L.T] and Pick Pack Time [P/P time] and Stock is available then system considers T.L.T or P/P time whichever is higher.

EX: If we have,

Transportation Lead Time [T.L.T] – 7 days

Pick Pack Time [P/P Time] – 3 days

Replenishment Lead Time [R.L.T] – 10 days and

Stock is Not Available then system considers R.L.T + P/P time or T.L.T whichever is higher.

| 1. Customer Requested Delivery Date

| 2. Pick Pack – Loading Time

| |||||||||||||

| 3. Sale Order Creation Date

| 4. Replenishment Lead Time [R.L.T] It will be maintained in Material Master MRP3 View

| |||||||||||||

5. Availability Check Control To consider the RLT Days in Delivery Schedule from Material Master, “Check without RLT” in Tcode-OVZ9 should be Un checked

| ||||||||||||||

6. Backward Delivery Scheduling Success In this scenario the Customer Requested Delivery date met for 60 Quantity so Backward Scheduling Success.

| ||||||||||||||

7. Backward Delivery Scheduling Process Delivery Creation Date OR Transportation Planning Date – 10.01.2021 P.G.I date – 19.01.2022 Customer Goods Receiving Date – 24.01.2022

| ||||||||||||||

Scenario 16 of 16

Conclusion:

The above 16 Scenarios about Delivery Scheduling in OTC process in SAP SD covers all possible parameters where in any Business may need to analyze/predict the possible ways of Delivery Scheduling of the Goods which need to be delivered to their End Customer.

Kindly provide the comments or Questions if you have any about the Subject Scenarios.

Best Regards,

Masood P

Knowledge Sharing is Power

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

ABAP

1 -

API Rules

1 -

c4c

1 -

CAP development

1 -

clean-core

1 -

CRM

1 -

Custom Key Metrics

1 -

Customer Data

1 -

Determination

1 -

Determinations

1 -

Introduction

1 -

KYMA

1 -

Kyma Functions

1 -

open SAP

1 -

RAP development

1 -

Sales and Service Cloud Version 2

1 -

Sales Cloud

1 -

Sales Cloud v2

1 -

SAP

1 -

SAP Community

1 -

SAP CPQ

1 -

SAP CRM Web UI

1 -

SAP Customer Data Cloud

1 -

SAP Customer Experience

1 -

SAP CX

1 -

SAP CX extensions

1 -

SAP Integration Suite

1 -

SAP Sales Cloud v2

1 -

SAP Service Cloud v2

1 -

SAP Service Cloud Version 2

1 -

Service and Social ticket configuration

1 -

Service Cloud v2

1 -

side-by-side extensions

1 -

Ticket configuration in SAP C4C

1 -

Validation

1 -

Validations

1

- Power of E-commerce Subscription Models in Increasing Conversions and Boosting Average Order Value in CRM and CX Blogs by SAP

- Hi Everyone, Can you please share me the all list of BADI Available for SAP SD. in CRM and CX Questions

- SAP Commerce Cloud Q1 ‘24 Release Highlights in CRM and CX Blogs by SAP

- What is planned for the 2405 release of SAP Variant Configuration and Pricing? in CRM and CX Blogs by SAP

- Effectively adopting Recurring Service process from S/4 HANA Service Management into your business in CRM and CX Blogs by SAP