- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Contribution View guide for SAP PLM Recipe Develop...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member39

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

01-28-2022

9:56 AM

About the Author

I am a Product Owner for SAP PLM Process Industries, helping customers and defining requirements towards the development team.

Related blog posts

Part 1 - Basic concept

Part 2 - Layouts, per stream calculation, not maintained data and nutrients

Part 3 - Composition, Cost, Intra-formula contribution calculations, losses

Part 4 - Scaling, exporting, PO limits, Energy based contribution

1 Introduction

This guide is meant to give an overview on the Contribution view within SAP PLM Recipe Development. As the content would be too much for a single blog post I separated it into smaller chunks (see above). I will focus on to describing the functionalities that are available there and to give some hints on how to start working with it. I will also mention some important aspects from my perspective. This guide is not meant to cover all the functionalities in detail. Information also can be found on Help Portal see here.

2 Prerequisites

Contribution view is introduced with the SAP S/4HANA On-Premise 1909 release thus SAP S/4HANA On-Premise 1909 or later release can be used. PLM Recipe Development with properly configured EHS Specification Management and Recipe Development shall be available. Relevant standard recipe calculations should run (Intra-formula, Cost, Composition, Hierarchical Nutrient, total solids/evaporation) on the existing recipe formula screen.

3 Basic Concept

The main purpose with this screen is to use it as a formulation tool (not just as a data repository). The main target user for it is the formula developer who creates recipe formulas. This guide is focusing on their point of view.

The Contribution view can be found on the recipe screen under Formula > Contribution.

Contribution View (Source SAP)

Contribution view functionalities by design are an integrated part of the recipe screen. What does this mean practically, you may wonder?

This means that certain functions are re-used from other screens. There are objects that are defined/created on other screens, but visualised and used by the contribution view. Good examples are the following:

- Process hierarchy elements: Stage, operation, actions are defined under the process tab, but the actual structure is used by the contribution view to visualise them.

- Key parameters: for contribution calculations are defined in the key parameters header section.

- Cost calculation source types (manual, material, Specification😞 Also defined in the cost tab but are displayed by the contribution view.

The following picture describes the basic concept how the Contribution view is built

Overview (source SAP)

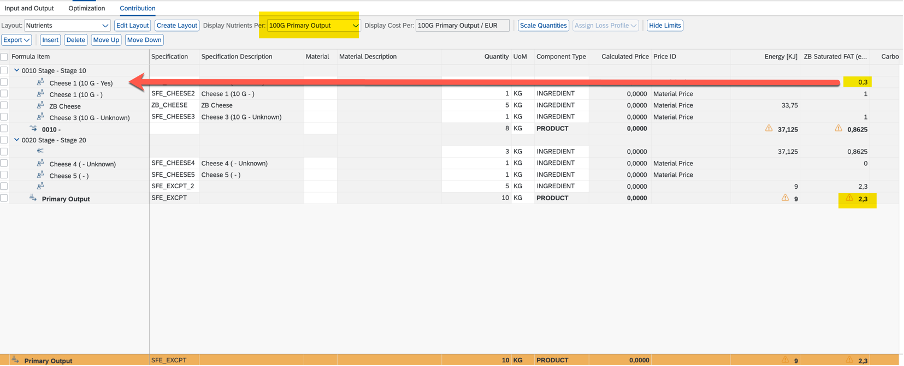

3.1 “Act” section

This is the part where your actual recipe structure with all the formula items can be seen, organised into process hierarchy nodes. The actual recipe process hierarchy can be defined under the process tab. If you have a flat recipe just with formula items, then it will be a simple list. Quantity, UOM, Component type columns are part of this section as well. These are the columns where you as a formula developer can change values according to your needs.

Suggestion: These columns in this section shall be kept together and fixed (always visible, cannot be scrolled) in your layout.

You can also notice that the Primary Output line can be found at the bottom of the hierarchy (opposite to the input/output tab where PO is on the top).

3.2 “Analyze” section

In my opinion this the most beneficial part of the screen. Each individual column here can be defined by the formula developer (via the related user specific layout – will be discussed later), which can give a huge flexibility content wise. You can see here individual nutrients, composition items as columns as well as intra-formula columns (Mass per PO etc.) based on your needs. In the cells you can see what I call contribution values related to each input ingredient.

Example:

This picture shows how the value shall be read here. Example shows that „ZB saturated FAT” nutrient has a total of 2.3g in a 100 g of Primary Output where 0.3g (out of it) is coming from the „Cheese 1 (10g – yes)” ingredient.

Example (Source SAP)

3.3 “Evaluate” section

This where you can see the Primary Output line with all the values related to the reference quantity of the PO and see the min/target/max limit lines per column. These values coming from the Primary Output specification (from upper/lower limits) if they are maintained there.

In my next post functional details will come starting with the layout handling and nutrients. Stay tuned.

- SAP Managed Tags:

- SAP Recipe Development,

- SAP S/4HANA,

- PLM (Product Lifecycle Management)

Labels:

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

155 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Recipe Development RMWB Edit or Create Issue in Enterprise Resource Planning Q&A

- Efficient management of vendor-built custom SAP developments in Enterprise Resource Planning Blogs by Members

- Manufacturing in SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Exploring the SAP S/4HANA 2023 Fully Activated Appliance: Key Features in Enterprise Resource Planning Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 8 | |

| 6 | |

| 6 | |

| 5 | |

| 4 | |

| 4 | |

| 4 | |

| 4 |