- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Value-Added Services (VAS) in SAP EWM

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

krishnakumar_ch

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

12-21-2021

3:44 PM

Introduction:

In this blog post you will learn about the value-added service in SAP EWM. There are some products which needs VAS activities such as labelling, painting, polishing assembling, packing etc. Additionally, there are materials which needs to be stored for a long time in a warehouse and this would require VAS activities like oiling and repacking before storage.

VAS process can be employed either in inbound or outbound processes. Moreover, it can be performed alongside kit to stock and kit to order processes. The VAS activities will be carried out in a special work center called VAS work center. The following approach discussed in this blog post explains the VAS order in inbound process with POSC (Process oriented storage control).

Solution Approach:

The below mentioned configuration steps can be employed to achieve this functionality:

Create warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Warehouse Process Type.

Warehouse Process Type-N365 (To move Goods from Door to GR Zone)

Warehouse Process Type-N361 (To move Goods from GR Zone to VAS work center)

Warehouse Process Type-N013 (To move Goods VAS work center to Final put-away bin)

Create control indicators using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Control Indicators for Determining Warehouse Process Types.

Assign this control indicator to the respective document type, item type and warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Determine Warehouse Process Type.

Create External Storage Process Step using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Process-Oriented Storage Control.

Next map the source and destination information along with warehouse process type for those External steps created above.

Now define Storage Process as shown below:

Then assign these External steps to this Storage Process as shown below:

Finally assign this Storage process: NI03 to the warehouse process type: N013 using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Warehouse Process Type.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Work Center -> Specify Work Center Layout.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Work Center -> Define Work Center.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> SCM Basis -> Master Data -> Product -> Product Groups ->Define Product Group Types.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> SCM Basis -> Master Data -> Product -> Product Groups ->Define Product Groups.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Activate Order Document Management for VAS.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Define Relevance for VAS.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Warehouse Number-Dependent VAS Settings.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Storage Type Search Sequence for Put away.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Assign Storage Types to Storage Type Search Sequence.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Put-away Control Indicator.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Specify Storage Type Search for Putaway.

Testing:

Inbound delivery screen can be reached using the t-code:/SCWM/PRDI.

Enter the quantity of Auxiliary Product and complete the VAS order by changing the status either with or without quantity deviation.

Conclusion:

This blog post walks you through various steps involved in Value-added service with test results.

Note: In the above mentioned case auxiliary product stock was not maintained in the warehouse . In case if you want to record the auxiliary product stock in the warehouse then follow this below mentioned steps:

In this blog post you will learn about the value-added service in SAP EWM. There are some products which needs VAS activities such as labelling, painting, polishing assembling, packing etc. Additionally, there are materials which needs to be stored for a long time in a warehouse and this would require VAS activities like oiling and repacking before storage.

VAS process can be employed either in inbound or outbound processes. Moreover, it can be performed alongside kit to stock and kit to order processes. The VAS activities will be carried out in a special work center called VAS work center. The following approach discussed in this blog post explains the VAS order in inbound process with POSC (Process oriented storage control).

Solution Approach:

The below mentioned configuration steps can be employed to achieve this functionality:

- In this case, goods are passed through various locations in the warehouse before reaching the final put away. To achieve each movement, a warehouse task to be created and for every warehouse task creation a warehouse process type needs to be defined.

Create warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Warehouse Process Type.

Warehouse Process Type-N365 (To move Goods from Door to GR Zone)

Warehouse Process Type-N361 (To move Goods from GR Zone to VAS work center)

Warehouse Process Type-N013 (To move Goods VAS work center to Final put-away bin)

- In the inbound delivery, the warehouse process type: N013 should be assigned to the delivery item level. To determine this warehouse process type, a control indicator should be defined and assigned to the respective warehouse process type.

Create control indicators using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Control Indicators for Determining Warehouse Process Types.

Assign this control indicator to the respective document type, item type and warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Determine Warehouse Process Type.

- In the above step a warehouse process type is defined for each movement following which a Process-oriented storage control (POSC) is defined to execute this movement in a sequenced way.

Create External Storage Process Step using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Process-Oriented Storage Control.

Next map the source and destination information along with warehouse process type for those External steps created above.

Now define Storage Process as shown below:

Then assign these External steps to this Storage Process as shown below:

Finally assign this Storage process: NI03 to the warehouse process type: N013 using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Warehouse Process Type.

- Create a new work center layout using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Work Center -> Specify Work Center Layout.

- Create a new work center by assigning the work center layout, External step, Storage type and Inbound Section using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Work Center -> Define Work Center.

- Assign the storage bin to the work center using the transaction code:/SCWM/TWORKST.

- Define Product Group Types using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> SCM Basis -> Master Data -> Product -> Product Groups ->Define Product Group Types.

- Define Product Groups using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> SCM Basis -> Master Data -> Product -> Product Groups ->Define Product Groups.

- Activate order document management for VAS using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Activate Order Document Management for VAS.

- Define VAS Relevance by mentioning the Document type, Item type, Product Group, Pack spec Procedure, Partner Role and Date/Time Type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Define Relevance for VAS.

- Define VAS settings for the respective Warehouse Number by assigning the Product Group Type and VAS number range using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Value-Added Services (VAS) -> Warehouse Number-Dependent VAS Settings.

- Create a storage type search type search sequence using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Storage Type Search Sequence for Put away.

- Assign storage types to storage type search sequence using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Assign Storage Types to Storage Type Search Sequence.

- Define Put-away control indicator using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Put-away Control Indicator.

- Maintain the determination of storage type search sequence for Put-away using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Specify Storage Type Search for Putaway.

- Maintain the Product Group and Product Group Type in the product master using the transaction code: /SAPAPO/MAT1.

- Maintain the warehouse product master by mentioning the process type determination indicator and Put-away control indicator using the transaction code:/SCWM/MAT1.

- Finally, the pack spec will be maintained by providing the condition record and packaging material using the transaction code:/SCWM/PACKSPEC.

Testing:

- Inbound delivery and VAS order is created.

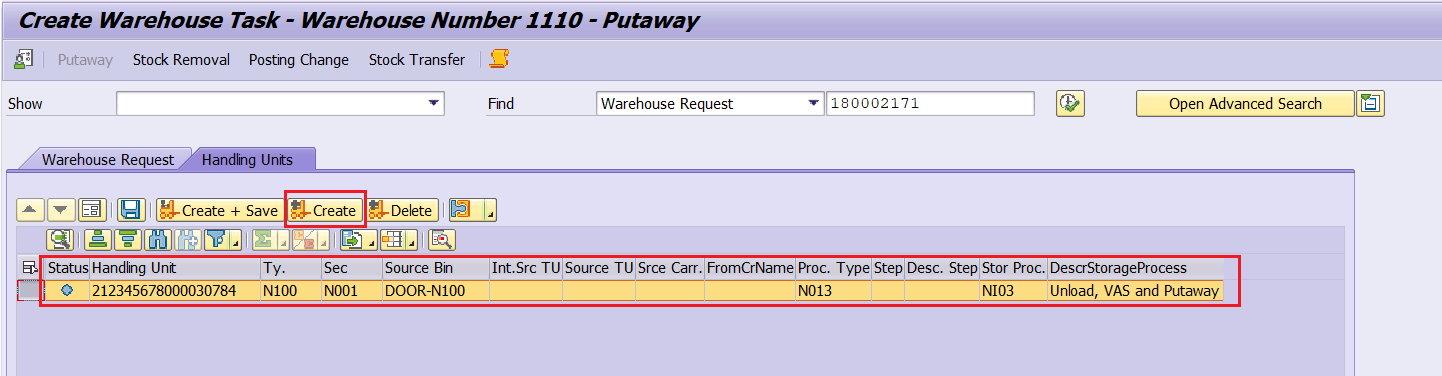

- In the delivery screen, create warehouse task manually by clicking on CREATE button and then SAVE.

Inbound delivery screen can be reached using the t-code:/SCWM/PRDI.

- Warehouse task can be viewed in the monitor screen using the transaction code:/SCWM/MON.

- Confirm the Warehouse order using the transaction code:/SCWM/TO_CONF so that the Handling unit will be moved from Door to the GR zone and it consequently triggers a new warehouse order.

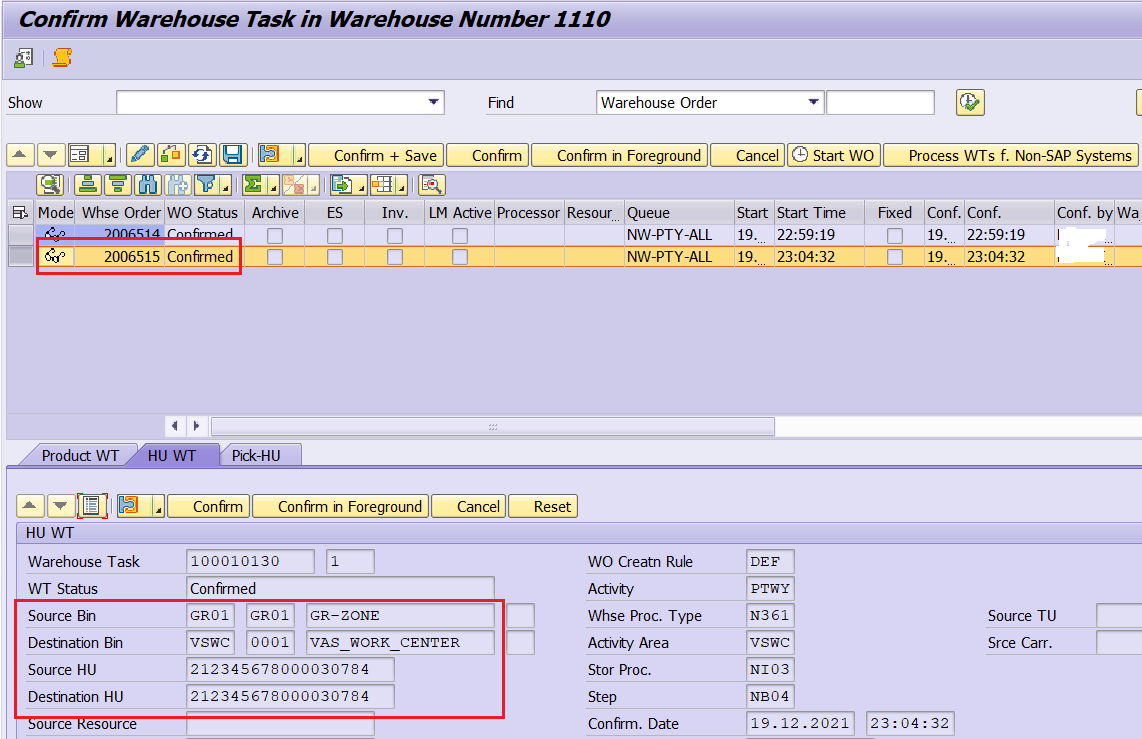

- Confirm the new warehouse order created using the transaction code:/SCWM/TO_CONF so that Handling unit will be moved from GR zone to VAS work center.

- Perform the VAS activities in the VAS work center using the transaction code:/SCWM/VASEXEC.

Enter the quantity of Auxiliary Product and complete the VAS order by changing the status either with or without quantity deviation.

- Once the VAS activities are completed for the respective VAS order, then select the Handling unit and click on “Complete Process Step for HU”. By doing this Put-away warehouse order will be enabled to perform the put-away activity.

- VAS order is completed, and it can be viewed using the transaction code: /SCWM/VAS_I.

- Finally, confirm the warehouse order created using the transaction code:/SCWM/TO_CONF so that Handling unit will be moved from VAS work center to the final Put-away bin.

- The inbound delivery is marked as completed once the goods are moved to the final put away bin.

Conclusion:

This blog post walks you through various steps involved in Value-added service with test results.

Note: In the above mentioned case auxiliary product stock was not maintained in the warehouse . In case if you want to record the auxiliary product stock in the warehouse then follow this below mentioned steps:

- Enable the "Consumptn-Rel.VAS" indicator in the warehouse product master under the warehouse tab using the t-code:/SCWM/MAT1.

- Then assign this storage bin to a workcenter or to a warehouse number from where you post the auxiliary products using the t-code:/SCWM/73000001.

20 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- Smartforms assigned to technician cannot be edited by a service leader in Supply Chain Management Q&A

- Error While activating Odata service in Supply Chain Management Q&A

- Business Network for Logistics - Customer Onboarding Webinar Series in Supply Chain Management Blogs by SAP

- Announcement: New integration platform in SAP Business Network for Logistics in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |