- SAP Community

- Products and Technology

- Technology

- Technology Blogs by Members

- Sustainable Asset Integrity achieved by eliminatin...

Technology Blogs by Members

Explore a vibrant mix of technical expertise, industry insights, and tech buzz in member blogs covering SAP products, technology, and events. Get in the mix!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

RohanPatel

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

12-13-2021

3:31 PM

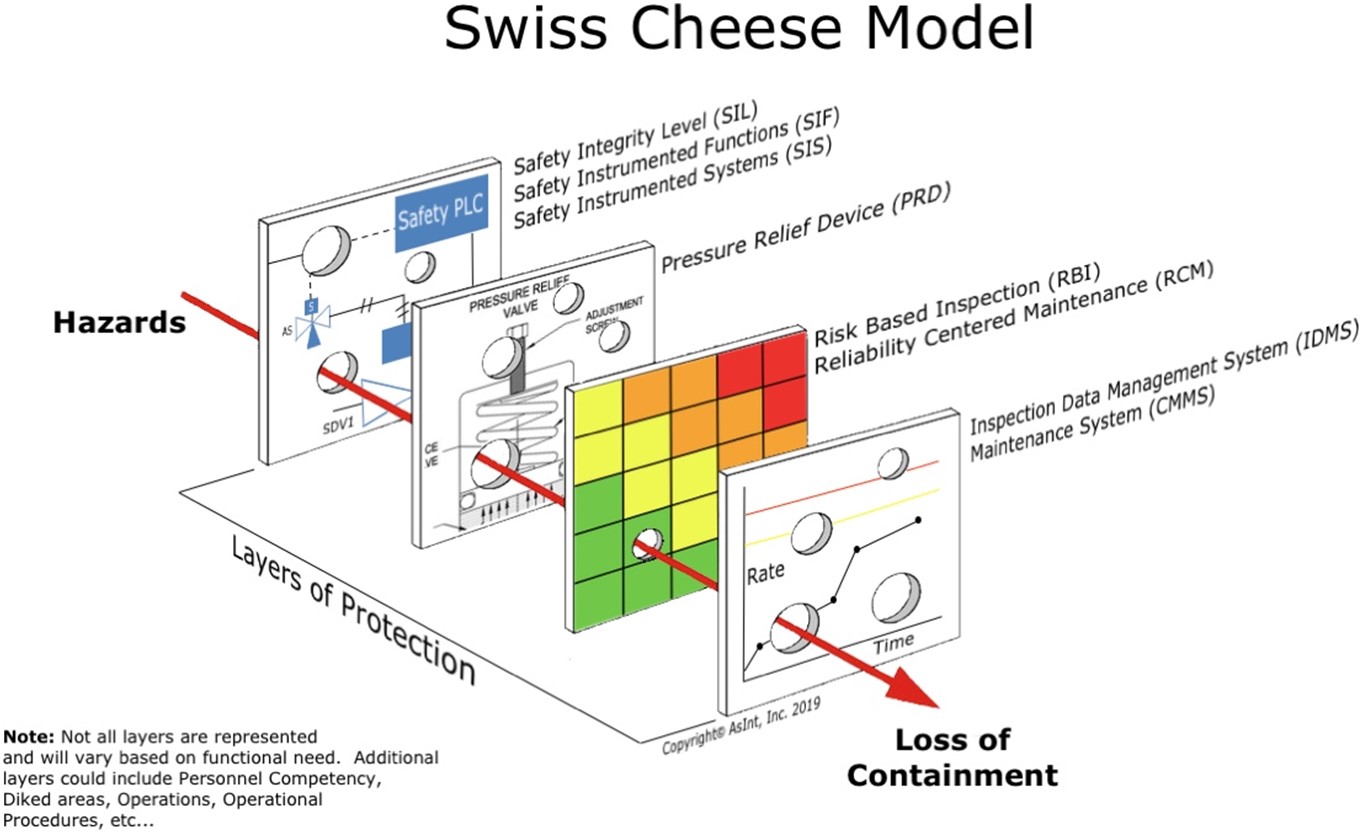

Within the Oil and Gas, Petrochem, and Chemical businesses, people are challenged with removing as many hazards as possible to avoid Loss of Containment. In the design of process systems, Layers of Protection are defined and implemented to ensure the product is never released to the environment or impacts the safety of people (HSE). These "Layers" can be physical, such as safety devices for isolation of the process if there is a leak or a training program to ensure operations, maintenance, and inspection personnel are qualified and equipped to perform their jobs with the highest level of competence. The layers are designed to be a multi-layered barrier for Preventing Loss of Containment. No single layer could be relied upon to ensure containment, but it makes up a comprehensive mitigation plan combined. However, each layer has "holes" or gaps, and when the holes line up, the potential for a release increase. This is referred to as the "Swiss Cheese Model."

Over the last few decades, OTS (off-the-shelf) software, or internally developed digital solutions, have been developed to manage the individual layers. These software functions are designed to address Inspections, Maintenance, Risk, Pressure Relief, Safety Instrumented Systems, and many other functions like HAZOP. In many cases, this has led to predicting or preventing failures. However, strong evidence suggests disconnected digital solutions designed to provide insight have had the opposite effect. These "data silos" prevent operators from seeing the whole picture regarding their "Layers of Protection" effectiveness, often leading to minor or catastrophic releases.

The solution to the "data silo" dilemma is to consolidate the software functions and data to address the various layers into a single platform. A single platform allows the operators to have a consolidated view of the physical and virtual assets designed to address a Loss of Containment. This big picture view greatly increases the knowledge of day-to-day decision-making to run the plant (OPEX) and future investments (CAPEX).

SAP has recently extended its traditional Asset and Work Management solutions to get closer to the physical asset with the addition of Asset Intelligence Network (AIN), Asset Strategy and Performance Management (ASPM), and SAP Predictive Asset Insights (PAI). The platform addresses each layer's large functions, including key data on the physical equipment and assessments and the work management and documentation of the assets that make up the containment layers. Within the platform, there are interconnected Apps to address FMEA (Failure Mode and Effect Analysis) and RCM (Reliability Centered Maintenance). Additionally, the platform allows for SAP partners, like AsInt, Inc., to develop Apps to address other layers such as Risk Based Inspection (RBI), Thickness Management (TM) and Inspections, and Safety Instrumented Systems (SIS) functions.

Performing these functions within the SAP ecosystem ensures all data needed to manage the Swiss cheese model is consolidated within the SAP Master Data. Removing data silos and disconnected work processes.

About AsInt. Inc

AsInt is changing how people develop, deliver, and access software for the oil and gas and petrochemical industry. Our goal is to create a full suite of applications that meet a range of asset integrity needs no matter the platform. The software is accessible via app stores and fit's purpose ease of use software.

Contact Information:

rohanpatel#about

CEO at AsInt Inc.

This information has already been published on the below reference link:

https://www.sap.com/products/asset-strategy-performance.html

https://asint.net/asset-integrity-swiss-cheese-and-data-silos

Over the last few decades, OTS (off-the-shelf) software, or internally developed digital solutions, have been developed to manage the individual layers. These software functions are designed to address Inspections, Maintenance, Risk, Pressure Relief, Safety Instrumented Systems, and many other functions like HAZOP. In many cases, this has led to predicting or preventing failures. However, strong evidence suggests disconnected digital solutions designed to provide insight have had the opposite effect. These "data silos" prevent operators from seeing the whole picture regarding their "Layers of Protection" effectiveness, often leading to minor or catastrophic releases.

The solution to the "data silo" dilemma is to consolidate the software functions and data to address the various layers into a single platform. A single platform allows the operators to have a consolidated view of the physical and virtual assets designed to address a Loss of Containment. This big picture view greatly increases the knowledge of day-to-day decision-making to run the plant (OPEX) and future investments (CAPEX).

SAP has recently extended its traditional Asset and Work Management solutions to get closer to the physical asset with the addition of Asset Intelligence Network (AIN), Asset Strategy and Performance Management (ASPM), and SAP Predictive Asset Insights (PAI). The platform addresses each layer's large functions, including key data on the physical equipment and assessments and the work management and documentation of the assets that make up the containment layers. Within the platform, there are interconnected Apps to address FMEA (Failure Mode and Effect Analysis) and RCM (Reliability Centered Maintenance). Additionally, the platform allows for SAP partners, like AsInt, Inc., to develop Apps to address other layers such as Risk Based Inspection (RBI), Thickness Management (TM) and Inspections, and Safety Instrumented Systems (SIS) functions.

Performing these functions within the SAP ecosystem ensures all data needed to manage the Swiss cheese model is consolidated within the SAP Master Data. Removing data silos and disconnected work processes.

About AsInt. Inc

AsInt is changing how people develop, deliver, and access software for the oil and gas and petrochemical industry. Our goal is to create a full suite of applications that meet a range of asset integrity needs no matter the platform. The software is accessible via app stores and fit's purpose ease of use software.

Contact Information:

rohanpatel#about

CEO at AsInt Inc.

This information has already been published on the below reference link:

https://www.sap.com/products/asset-strategy-performance.html

https://asint.net/asset-integrity-swiss-cheese-and-data-silos

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"automatische backups"

1 -

"regelmäßige sicherung"

1 -

"TypeScript" "Development" "FeedBack"

1 -

505 Technology Updates 53

1 -

ABAP

14 -

ABAP API

1 -

ABAP CDS Views

2 -

ABAP CDS Views - BW Extraction

1 -

ABAP CDS Views - CDC (Change Data Capture)

1 -

ABAP class

2 -

ABAP Cloud

2 -

ABAP Development

5 -

ABAP in Eclipse

1 -

ABAP Platform Trial

1 -

ABAP Programming

2 -

abap technical

1 -

absl

2 -

access data from SAP Datasphere directly from Snowflake

1 -

Access data from SAP datasphere to Qliksense

1 -

Accrual

1 -

action

1 -

adapter modules

1 -

Addon

1 -

Adobe Document Services

1 -

ADS

1 -

ADS Config

1 -

ADS with ABAP

1 -

ADS with Java

1 -

ADT

2 -

Advance Shipping and Receiving

1 -

Advanced Event Mesh

3 -

AEM

1 -

AI

7 -

AI Launchpad

1 -

AI Projects

1 -

AIML

9 -

Alert in Sap analytical cloud

1 -

Amazon S3

1 -

Analytical Dataset

1 -

Analytical Model

1 -

Analytics

1 -

Analyze Workload Data

1 -

annotations

1 -

API

1 -

API and Integration

3 -

API Call

2 -

Application Architecture

1 -

Application Development

5 -

Application Development for SAP HANA Cloud

3 -

Applications and Business Processes (AP)

1 -

Artificial Intelligence

1 -

Artificial Intelligence (AI)

5 -

Artificial Intelligence (AI) 1 Business Trends 363 Business Trends 8 Digital Transformation with Cloud ERP (DT) 1 Event Information 462 Event Information 15 Expert Insights 114 Expert Insights 76 Life at SAP 418 Life at SAP 1 Product Updates 4

1 -

Artificial Intelligence (AI) blockchain Data & Analytics

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise Oil Gas IoT Exploration Production

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise sustainability responsibility esg social compliance cybersecurity risk

1 -

ASE

1 -

ASR

2 -

ASUG

1 -

Attachments

1 -

Authorisations

1 -

Automating Processes

1 -

Automation

2 -

aws

2 -

Azure

1 -

Azure AI Studio

1 -

B2B Integration

1 -

Backorder Processing

1 -

Backup

1 -

Backup and Recovery

1 -

Backup schedule

1 -

BADI_MATERIAL_CHECK error message

1 -

Bank

1 -

BAS

1 -

basis

2 -

Basis Monitoring & Tcodes with Key notes

2 -

Batch Management

1 -

BDC

1 -

Best Practice

1 -

bitcoin

1 -

Blockchain

3 -

bodl

1 -

BOP in aATP

1 -

BOP Segments

1 -

BOP Strategies

1 -

BOP Variant

1 -

BPC

1 -

BPC LIVE

1 -

BTP

12 -

BTP Destination

2 -

Business AI

1 -

Business and IT Integration

1 -

Business application stu

1 -

Business Application Studio

1 -

Business Architecture

1 -

Business Communication Services

1 -

Business Continuity

1 -

Business Data Fabric

3 -

Business Partner

12 -

Business Partner Master Data

10 -

Business Technology Platform

2 -

Business Trends

4 -

CA

1 -

calculation view

1 -

CAP

3 -

Capgemini

1 -

CAPM

1 -

Catalyst for Efficiency: Revolutionizing SAP Integration Suite with Artificial Intelligence (AI) and

1 -

CCMS

2 -

CDQ

12 -

CDS

2 -

Cental Finance

1 -

Certificates

1 -

CFL

1 -

Change Management

1 -

chatbot

1 -

chatgpt

3 -

CL_SALV_TABLE

2 -

Class Runner

1 -

Classrunner

1 -

Cloud ALM Monitoring

1 -

Cloud ALM Operations

1 -

cloud connector

1 -

Cloud Extensibility

1 -

Cloud Foundry

4 -

Cloud Integration

6 -

Cloud Platform Integration

2 -

cloudalm

1 -

communication

1 -

Compensation Information Management

1 -

Compensation Management

1 -

Compliance

1 -

Compound Employee API

1 -

Configuration

1 -

Connectors

1 -

Consolidation Extension for SAP Analytics Cloud

2 -

Control Indicators.

1 -

Controller-Service-Repository pattern

1 -

Conversion

1 -

Cosine similarity

1 -

cryptocurrency

1 -

CSI

1 -

ctms

1 -

Custom chatbot

3 -

Custom Destination Service

1 -

custom fields

1 -

Customer Experience

1 -

Customer Journey

1 -

Customizing

1 -

cyber security

3 -

Data

1 -

Data & Analytics

1 -

Data Aging

1 -

Data Analytics

2 -

Data and Analytics (DA)

1 -

Data Archiving

1 -

Data Back-up

1 -

Data Governance

5 -

Data Integration

2 -

Data Quality

12 -

Data Quality Management

12 -

Data Synchronization

1 -

data transfer

1 -

Data Unleashed

1 -

Data Value

8 -

database tables

1 -

Datasphere

2 -

datenbanksicherung

1 -

dba cockpit

1 -

dbacockpit

1 -

Debugging

2 -

Delimiting Pay Components

1 -

Delta Integrations

1 -

Destination

3 -

Destination Service

1 -

Developer extensibility

1 -

Developing with SAP Integration Suite

1 -

Devops

1 -

digital transformation

1 -

Documentation

1 -

Dot Product

1 -

DQM

1 -

dump database

1 -

dump transaction

1 -

e-Invoice

1 -

E4H Conversion

1 -

Eclipse ADT ABAP Development Tools

2 -

edoc

1 -

edocument

1 -

ELA

1 -

Embedded Consolidation

1 -

Embedding

1 -

Embeddings

1 -

Employee Central

1 -

Employee Central Payroll

1 -

Employee Central Time Off

1 -

Employee Information

1 -

Employee Rehires

1 -

Enable Now

1 -

Enable now manager

1 -

endpoint

1 -

Enhancement Request

1 -

Enterprise Architecture

1 -

ETL Business Analytics with SAP Signavio

1 -

Euclidean distance

1 -

Event Dates

1 -

Event Driven Architecture

1 -

Event Mesh

2 -

Event Reason

1 -

EventBasedIntegration

1 -

EWM

1 -

EWM Outbound configuration

1 -

EWM-TM-Integration

1 -

Existing Event Changes

1 -

Expand

1 -

Expert

2 -

Expert Insights

2 -

Fiori

14 -

Fiori Elements

2 -

Fiori SAPUI5

12 -

Flask

1 -

Full Stack

8 -

Funds Management

1 -

General

1 -

Generative AI

1 -

Getting Started

1 -

GitHub

8 -

Grants Management

1 -

groovy

1 -

GTP

1 -

HANA

6 -

HANA Cloud

2 -

Hana Cloud Database Integration

2 -

HANA DB

2 -

HANA XS Advanced

1 -

Historical Events

1 -

home labs

1 -

HowTo

1 -

HR Data Management

1 -

html5

8 -

HTML5 Application

1 -

Identity cards validation

1 -

idm

1 -

Implementation

1 -

input parameter

1 -

instant payments

1 -

Integration

3 -

Integration Advisor

1 -

Integration Architecture

1 -

Integration Center

1 -

Integration Suite

1 -

intelligent enterprise

1 -

iot

1 -

Java

1 -

job

1 -

Job Information Changes

1 -

Job-Related Events

1 -

Job_Event_Information

1 -

joule

4 -

Journal Entries

1 -

Just Ask

1 -

Kerberos for ABAP

8 -

Kerberos for JAVA

8 -

KNN

1 -

Launch Wizard

1 -

learning content

2 -

Life at SAP

4 -

lightning

1 -

Linear Regression SAP HANA Cloud

1 -

local tax regulations

1 -

LP

1 -

Machine Learning

2 -

Marketing

1 -

Master Data

3 -

Master Data Management

14 -

Maxdb

2 -

MDG

1 -

MDGM

1 -

MDM

1 -

Message box.

1 -

Messages on RF Device

1 -

Microservices Architecture

1 -

Microsoft Universal Print

1 -

Middleware Solutions

1 -

Migration

5 -

ML Model Development

1 -

Modeling in SAP HANA Cloud

8 -

Monitoring

3 -

MTA

1 -

Multi-Record Scenarios

1 -

Multiple Event Triggers

1 -

Neo

1 -

New Event Creation

1 -

New Feature

1 -

Newcomer

1 -

NodeJS

2 -

ODATA

2 -

OData APIs

1 -

odatav2

1 -

ODATAV4

1 -

ODBC

1 -

ODBC Connection

1 -

Onpremise

1 -

open source

2 -

OpenAI API

1 -

Oracle

1 -

PaPM

1 -

PaPM Dynamic Data Copy through Writer function

1 -

PaPM Remote Call

1 -

PAS-C01

1 -

Pay Component Management

1 -

PGP

1 -

Pickle

1 -

PLANNING ARCHITECTURE

1 -

Popup in Sap analytical cloud

1 -

PostgrSQL

1 -

POSTMAN

1 -

Process Automation

2 -

Product Updates

4 -

PSM

1 -

Public Cloud

1 -

Python

4 -

Qlik

1 -

Qualtrics

1 -

RAP

3 -

RAP BO

2 -

Record Deletion

1 -

Recovery

1 -

recurring payments

1 -

redeply

1 -

Release

1 -

Remote Consumption Model

1 -

Replication Flows

1 -

research

1 -

Resilience

1 -

REST

1 -

REST API

1 -

Retagging Required

1 -

Risk

1 -

Rolling Kernel Switch

1 -

route

1 -

rules

1 -

S4 HANA

1 -

S4 HANA Cloud

1 -

S4 HANA On-Premise

1 -

S4HANA

3 -

S4HANA_OP_2023

2 -

SAC

10 -

SAC PLANNING

9 -

SAP

4 -

SAP ABAP

1 -

SAP Advanced Event Mesh

1 -

SAP AI Core

8 -

SAP AI Launchpad

8 -

SAP Analytic Cloud Compass

1 -

Sap Analytical Cloud

1 -

SAP Analytics Cloud

4 -

SAP Analytics Cloud for Consolidation

3 -

SAP Analytics Cloud Story

1 -

SAP analytics clouds

1 -

SAP BAS

1 -

SAP Basis

6 -

SAP BODS

1 -

SAP BODS certification.

1 -

SAP BTP

21 -

SAP BTP Build Work Zone

2 -

SAP BTP Cloud Foundry

6 -

SAP BTP Costing

1 -

SAP BTP CTMS

1 -

SAP BTP Innovation

1 -

SAP BTP Migration Tool

1 -

SAP BTP SDK IOS

1 -

SAP Build

11 -

SAP Build App

1 -

SAP Build apps

1 -

SAP Build CodeJam

1 -

SAP Build Process Automation

3 -

SAP Build work zone

10 -

SAP Business Objects Platform

1 -

SAP Business Technology

2 -

SAP Business Technology Platform (XP)

1 -

sap bw

1 -

SAP CAP

2 -

SAP CDC

1 -

SAP CDP

1 -

SAP CDS VIEW

1 -

SAP Certification

1 -

SAP Cloud ALM

4 -

SAP Cloud Application Programming Model

1 -

SAP Cloud Integration for Data Services

1 -

SAP cloud platform

8 -

SAP Companion

1 -

SAP CPI

3 -

SAP CPI (Cloud Platform Integration)

2 -

SAP CPI Discover tab

1 -

sap credential store

1 -

SAP Customer Data Cloud

1 -

SAP Customer Data Platform

1 -

SAP Data Intelligence

1 -

SAP Data Migration in Retail Industry

1 -

SAP Data Services

1 -

SAP DATABASE

1 -

SAP Dataspher to Non SAP BI tools

1 -

SAP Datasphere

10 -

SAP DRC

1 -

SAP EWM

1 -

SAP Fiori

2 -

SAP Fiori App Embedding

1 -

Sap Fiori Extension Project Using BAS

1 -

SAP GRC

1 -

SAP HANA

1 -

SAP HCM (Human Capital Management)

1 -

SAP HR Solutions

1 -

SAP IDM

1 -

SAP Integration Suite

9 -

SAP Integrations

4 -

SAP iRPA

2 -

SAP Learning Class

1 -

SAP Learning Hub

1 -

SAP Odata

2 -

SAP on Azure

1 -

SAP PartnerEdge

1 -

sap partners

1 -

SAP Password Reset

1 -

SAP PO Migration

1 -

SAP Prepackaged Content

1 -

SAP Process Automation

2 -

SAP Process Integration

2 -

SAP Process Orchestration

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Cloud for Finance

1 -

SAP S4HANA Cloud private edition

1 -

SAP Sandbox

1 -

SAP STMS

1 -

SAP successfactors

3 -

SAP SuccessFactors HXM Core

1 -

SAP Time

1 -

SAP TM

2 -

SAP Trading Partner Management

1 -

SAP UI5

1 -

SAP Upgrade

1 -

SAP Utilities

1 -

SAP-GUI

8 -

SAP_COM_0276

1 -

SAPBTP

1 -

SAPCPI

1 -

SAPEWM

1 -

sapmentors

1 -

saponaws

2 -

SAPS4HANA

1 -

SAPUI5

4 -

schedule

1 -

Secure Login Client Setup

8 -

security

9 -

Selenium Testing

1 -

SEN

1 -

SEN Manager

1 -

service

1 -

SET_CELL_TYPE

1 -

SET_CELL_TYPE_COLUMN

1 -

SFTP scenario

2 -

Simplex

1 -

Single Sign On

8 -

Singlesource

1 -

SKLearn

1 -

soap

1 -

Software Development

1 -

SOLMAN

1 -

solman 7.2

2 -

Solution Manager

3 -

sp_dumpdb

1 -

sp_dumptrans

1 -

SQL

1 -

sql script

1 -

SSL

8 -

SSO

8 -

Substring function

1 -

SuccessFactors

1 -

SuccessFactors Platform

1 -

SuccessFactors Time Tracking

1 -

Sybase

1 -

system copy method

1 -

System owner

1 -

Table splitting

1 -

Tax Integration

1 -

Technical article

1 -

Technical articles

1 -

Technology Updates

14 -

Technology Updates

1 -

Technology_Updates

1 -

terraform

1 -

Threats

1 -

Time Collectors

1 -

Time Off

2 -

Time Sheet

1 -

Time Sheet SAP SuccessFactors Time Tracking

1 -

Tips and tricks

2 -

toggle button

1 -

Tools

1 -

Trainings & Certifications

1 -

Transport in SAP BODS

1 -

Transport Management

1 -

TypeScript

2 -

ui designer

1 -

unbind

1 -

Unified Customer Profile

1 -

UPB

1 -

Use of Parameters for Data Copy in PaPM

1 -

User Unlock

1 -

VA02

1 -

Validations

1 -

Vector Database

2 -

Vector Engine

1 -

Visual Studio Code

1 -

VSCode

1 -

Web SDK

1 -

work zone

1 -

workload

1 -

xsa

1 -

XSA Refresh

1

- « Previous

- Next »

Related Content

- 10+ ways to reshape your SAP landscape with SAP Business Technology Platform – Blog 4 in Technology Blogs by SAP

- What you need to know about Finance in SAP S/4HANA Cloud, Public Edition in Technology Blogs by SAP

- 10+ ways to reshape your SAP landscape with SAP Business Technology Platform - Blog 3 in Technology Blogs by SAP

- What’s New in SAP HANA Cloud – March 2024 in Technology Blogs by SAP

- Modeling in SAP SuccessFactors Incentive Management in Technology Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 13 | |

| 11 | |

| 5 | |

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 |