- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- SAP Digital Manufacturing Cloud (DMC) 2111 - Relea...

Product Lifecycle Management Blogs by SAP

Dive into product lifecycle management news, learn about digitalizing PLM for the digital supply chain, and stay informed with product updates from SAP.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-16-2021

8:57 PM

Dear Colleagues,

We are excited to introduce you to the SAP Digital Manufacturing Cloud 2111 release. The 2111 release is pivotal in delivering our customers' performance and availability to run our cloud applications at the plant.

For Discrete Customers, we introduced additional Digital Manufacturing Cloud Edge Computing functionality. As well as Configure Next Numbers Using Material Groups, Create a Formula for a BOM Header Material, Assign Production Resources and Tools to an Operation Activity, and New API's.

For Process Customers, we introduced some very existing features:

- Weigh & Dispense plugin for the POD

- Support splitting SFC from the Order POD and assignment of alternative resources

- Improve extensibility by new published APIs

For Analytics, we introduced the first version of the Production Line Monitor application, an exciting new WYSIWIG tool for building your own operational displays.

Highlights:

New - Line Monitor for Process Orders ONLY

The newly developed capability in DMC enables shopfloor supervisors, who are responsible for the production line, to monitor, track and measure production to meet business goals using the "Production Line Monitor" plugins that are pre-delivered in DMC POD designer. Using the plugins, design the content required to monitor the production line in the POD designer. The line monitor provides insights on various perspectives such as the "Production target," "Production quality," "Assets," and "Overall equipment effectiveness." Get the insights on various perspectives mentioned earlier at a comprehensive overview level and dive deep to get the details on each perspective. The overview page from the perspective of "Production" provides a qualitative overview about the status of the orders actively executed in the production lines on the shop floor or plant floor to judge whether the considered production target for those orders is met or not w.r.t time.

Additionally, the detailed information page helps get visibility on the actual amount produced against planned production quantity at the order level. The overview page from the perspective of "Product Quality" provides a quick overview of the overall production situation whether the considered quality target for that shift is met or not. The detailed information on the yield and scarp for the respective active orders and the trends and aggregated values of the measurement of IoT sensors associated with the product quality can also be viewed and monitored in near real-time. The impact of asset availability and unplanned downtimes is provided in the "Asset view". Finally, the production lines OEE is presented in the monitoring application to help the supervisor focus on the source of the issues, thus helping to improve productivity and performance-driven by data.

New - SAP Modular Production

Processes, requirements, and processes in Manufacturing have constantly been changing over the last decades. The number of product variants is steadily increasing while product volume per variant is decreasing. This leads to challenges for many manufacturers who have automated and standardized their production over many years to increase efficiency and throughput for highly standardized products.

To support this trend, the SAP Industry 4. NOW solution 'SAP Modular Production' will enhance the Digital Manufacturing Cloud offering with the following capabilities:

1) Dynamic Routing & Ad-hoc Decisions

2) Work in Progress Transport

3) Supply to Manufacturing Cell

4) Visualization

5) Analytics

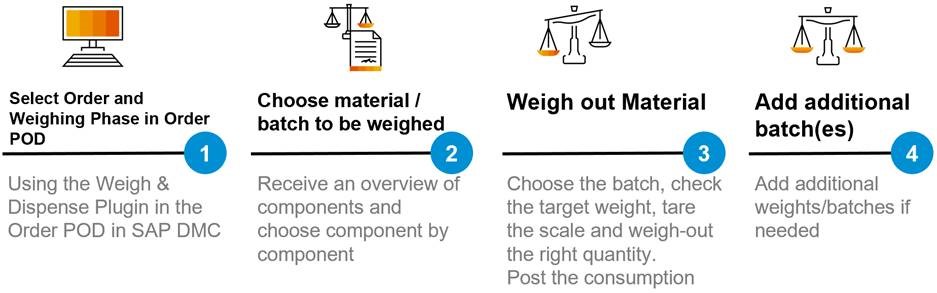

Process Manufacturing – Weigh & Dispense

SAP Digital Manufacturing Cloud for Execution in Process industries now supports the process of Weigh & Dispense as a standard POD UI. Weigh & dispense is the process of removing precisely specified amounts of bulk raw material from their source container and dispensing them into aliquots of specific quantities into other containers. It's a key part for many manufacturing processes to support for high precision recipe ingredient management and enhances our capabilities to integrate with weigh scale and material dispensing equipment. This process is simple and easy to follow, and the POD UIs guide the user to the appropriate next steps:

What's New Viewer - SAP Digital Manufacturing Cloud

ASSETS

SAP Digital Manufacturing Cloud (DMC): Home Page

SAP Digital Manufacturing Cloud 2111 - Release Highlights: Full List Here

SAP Digital Manufacturing Roadmaps: Customer Published

Thank You,

Rusty Baldwin & Sam Castro

- SAP Managed Tags:

- SAP Digital Manufacturing,

- SAP Manufacturing Execution,

- Digital Transformation

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- Quick Start guide for PLM system integration 3.0 Implementation in Product Lifecycle Management Blogs by SAP

- Striking the Perfect Balance in Product Lifecycle Management Blogs by SAP

- MII configuration and content transport management in Product Lifecycle Management Blogs by SAP

- Embedding Visualization into SAP Asset Performance Management Step by Step Guide in Product Lifecycle Management Blogs by SAP

- Exploring the Journey of SAP PLM Experts Becoming Authors in Product Lifecycle Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |