- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- EWM - Vendor Returns Process - Returns Delivery Vs...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Dang_Bao_Van

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-10-2021

11:17 AM

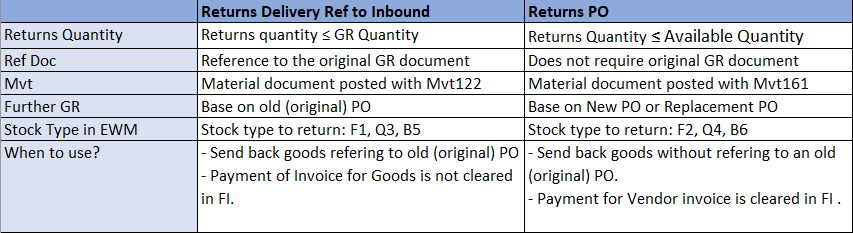

SAP offers 2 different processes of Vendor Returns: returns with Returns Delivery Ref to Inbound Delivery and returns with Returns PO. So what is the difference? In this blogs I will compare this 2 processes with EWM steps.

My Testing is based on Embedded EWM - S/4HANA 1909.

IMG: MM > Purchasing > Confirmations > Set Up Confirmation Control

Assign 0004 as Quantity Difference Profile

IMG: MM > Purchasing > Confirmations > Set Up Quantity Difference Profiles (GR Automotive)

IMG: MM > Purchasing > Confirmations > Define Internal Confirmation Categories

IMG: Logistics Execution > Shipping > Basic Shipping Functions > Shipping Point and Goods Receiving Point Determination > Assign Shipping Points

IMG: Material Management -> Purchasing -> Purchase Order -> Set up Stock Transport Order -> Define Shipping Data for Plants

Need to create a BP as Customer for Plants and assign BP here.

IMG: Logistics Execution > Shipping > Deliveries > Define Delivery Types

IMG: Logistics Execution > Shipping > Deliveries > Define Item Category Determination in Deliveries

Note: Assign GR Interims Storage Type 9010 to search sequence of Return Delivery

When using Returns PO, Vendor master data and Material Master data need some additional data as below.

For using Return Delivery, in Role Vendor, mark Vendor as Return Supplier.

For using Returns PO, maintain Customer roles for Sales.org & Distribution Channel. Assign Delivery Plant as plant where you returns stock.

For using Returns PO, maintain Sales View for material.

Step 1: Create Return Delivery Ref to Inbound

Tcode: /SCWM/PRDI

Before this step, a Inbound Delivery is created and GR is posted.

Stock is still in GR-ZONE, mean if you already putaway stock and confirmed putaway WT, you need manually transfer stock to GR Zone.

Step 2: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Note: Stock is taken from GR-ZONE to GI-ZONE

Step 3: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is completed.

Note: Stock Type is Q3 (or F1)

Material Document with Mvt 122 is created in S/4HANA

Step 1: Create Retuns PO

Tcode: ME21N

Select PO type - PO Return and mark Item as Return Item

Step 2: Create Outbound Delivery

Tcode: VL10B

Step 3: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Step 4: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is complete.

Note: Stock type is Q4 (or F2)

Material document is created with Mvt 161

*****

If you want to return stock rather than your original GR stock type, you must set up Stock Determination for other Stock type.

Example: GR with inbound delivery, stock type Q3. But you want to return stock with stock type Q4 or F2, it's possible.

IMG: EWM > Cross process Setting > Stock Determination

Create a Stock Determination Group and Assign Stock Determination.

You can create many stock Determination to picking more than 1 stock type for return.

Next step to assign Stock Determination Group to your Product Master.

/SCWM/MAT1

--- End ---

In which case will you use Returns Delivery Ref to Inbound or Returns PO? Feel free to question/comment on my Topics.

Regards,

Van Dang

Returns PO

https://help.sap.com/doc/cd4e70ed816d46aba0661d1cd5c1eabb/3.6/en-US/de6a3d45bb814393b04cff7fd6b9aefd...

Returns Delivery

https://help.sap.com/viewer/91b21005dded4984bcccf4a69ae1300c/2020.000/en-US/e263bd534f22b44ce1000000...

My Testing is based on Embedded EWM - S/4HANA 1909.

Compare Vendor Return Process with Returns Delivery Ref to Inbound and Returns PO

- Overall Process with EWM steps

- Comparation

Prerequisite

- Active BC Set - /SCWM/DLV_OUTBOUND_RETURN

Configuration

General Customizing

- Set up confirmation Control Key

IMG: MM > Purchasing > Confirmations > Set Up Confirmation Control

Assign 0004 as Quantity Difference Profile

IMG: MM > Purchasing > Confirmations > Set Up Quantity Difference Profiles (GR Automotive)

IMG: MM > Purchasing > Confirmations > Define Internal Confirmation Categories

- Shipping point determination

IMG: Logistics Execution > Shipping > Basic Shipping Functions > Shipping Point and Goods Receiving Point Determination > Assign Shipping Points

- Define shipping data (For Returns PO)

IMG: Material Management -> Purchasing -> Purchase Order -> Set up Stock Transport Order -> Define Shipping Data for Plants

Need to create a BP as Customer for Plants and assign BP here.

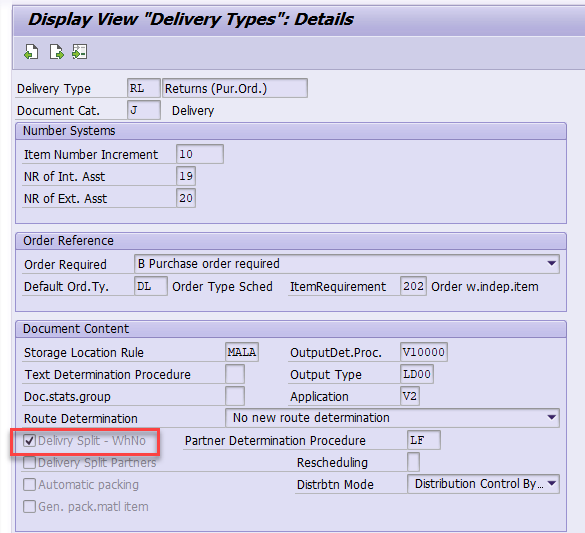

- Check "Delivery Split" in delivery Type

IMG: Logistics Execution > Shipping > Deliveries > Define Delivery Types

- Delivery Item Type Determination

IMG: Logistics Execution > Shipping > Deliveries > Define Item Category Determination in Deliveries

EWM Customizing

- Mapping Delivery Type and Item Type S/4HANA & EWM

- Determine WPT for Return Doc Type

- Define Storage search sequence

Note: Assign GR Interims Storage Type 9010 to search sequence of Return Delivery

- Determine Storage Type search sequence

Master data

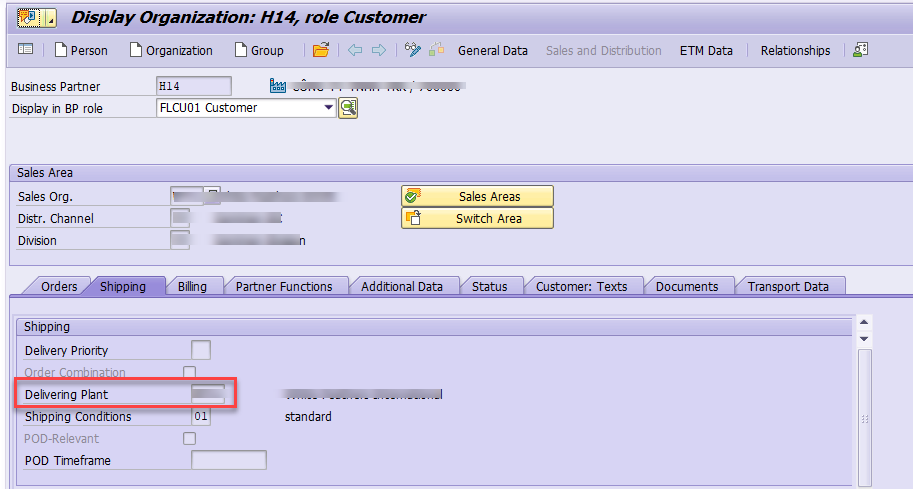

When using Returns PO, Vendor master data and Material Master data need some additional data as below.

- Vendor Master data:

For using Return Delivery, in Role Vendor, mark Vendor as Return Supplier.

For using Returns PO, maintain Customer roles for Sales.org & Distribution Channel. Assign Delivery Plant as plant where you returns stock.

- Material Master data:

For using Returns PO, maintain Sales View for material.

Testing

Vendor Returns - Using Returns Delivery Ref to Inbound Delivery

Step 1: Create Return Delivery Ref to Inbound

Tcode: /SCWM/PRDI

Before this step, a Inbound Delivery is created and GR is posted.

Stock is still in GR-ZONE, mean if you already putaway stock and confirmed putaway WT, you need manually transfer stock to GR Zone.

Step 2: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Note: Stock is taken from GR-ZONE to GI-ZONE

Step 3: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is completed.

Note: Stock Type is Q3 (or F1)

Material Document with Mvt 122 is created in S/4HANA

Vendor Returns - Using Returns PO

Step 1: Create Retuns PO

Tcode: ME21N

Select PO type - PO Return and mark Item as Return Item

Step 2: Create Outbound Delivery

Tcode: VL10B

Step 3: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Step 4: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is complete.

Note: Stock type is Q4 (or F2)

Material document is created with Mvt 161

*****

Important note!!!

If you want to return stock rather than your original GR stock type, you must set up Stock Determination for other Stock type.

Example: GR with inbound delivery, stock type Q3. But you want to return stock with stock type Q4 or F2, it's possible.

IMG: EWM > Cross process Setting > Stock Determination

Create a Stock Determination Group and Assign Stock Determination.

You can create many stock Determination to picking more than 1 stock type for return.

Next step to assign Stock Determination Group to your Product Master.

/SCWM/MAT1

--- End ---

In which case will you use Returns Delivery Ref to Inbound or Returns PO? Feel free to question/comment on my Topics.

Regards,

Van Dang

Reference

Returns PO

https://help.sap.com/doc/cd4e70ed816d46aba0661d1cd5c1eabb/3.6/en-US/de6a3d45bb814393b04cff7fd6b9aefd...

Returns Delivery

https://help.sap.com/viewer/91b21005dded4984bcccf4a69ae1300c/2020.000/en-US/e263bd534f22b44ce1000000...

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- EWM - Delivery Processing

24 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- Under-delivery return order in Supply Chain Management Q&A

- SAP Transportation Management Analytics in Supply Chain Management Blogs by SAP

- Received stock does not have inspection ID in ARM in Supply Chain Management Q&A

- SAP S/4 Hana SD Advanced Returns Management in Supply Chain Management Q&A

- What data sources can be used to combine "Customer Return ID" and "Invoice Request ID"? in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |