- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Staging to Production in SAP Extended Warehouse Ma...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Jörg_Michaelis

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-02-2021

11:01 AM

Today I would like to bring your attention a presentation our Product Management team has prepared that provides a detailed overview on Staging to Production in SAP EWM.

In a previous blog we published in 2020, we have already discussed about receiving from production, which is referring to the overall process of receiving the produced materials from a manufacturing order and then do the put away of received goods in the SAP Extended Warehouse Management system.

This time the blog post will cover the supply to production side of things, also known as staging to production. Staging to production refers to the overall process of picking the requested raw materials or components and supplying them to production with guidance from the Extended Warehouse Management system.

SAP EWM supports different options for staging to production, whether the staging was triggered by SAP EWM, a core system such as SAP ERP or SAP S/4HANA, or a production system such as SAP Manufacturing Execution (SAP ME), or SAP Digital Manufacturing Cloud (SAP DMC).

SAP ERP or SAP S/4HANA Triggered Staging to Production

When discussing staging to production triggered by the ERP system, aside from the three categories of staging scenarios (Staging for Production with Deliveries; Production Supply with Kanban; Production Supply with JIT Call) we need to first mention that these scenarios can take place in one of 4 organizational model options which define how the warehouse architecture is broadly configured within a system. These options are:

- PSA managed under Available for Sale (AFS) storage location

- PSA managed under separate EWM storage location

- PSA managed by non EWM storage location

- PSA managed under separate EWM warehouse

Below is a graphical representation of how these organizational models look like.

Most combinations between ERP triggered staging scenarios and organizational models were available in SAP EWM since EWM 7.0. You can read the full descriptions and differences of these scenarios in the slide deck linked in the introduction of this article.

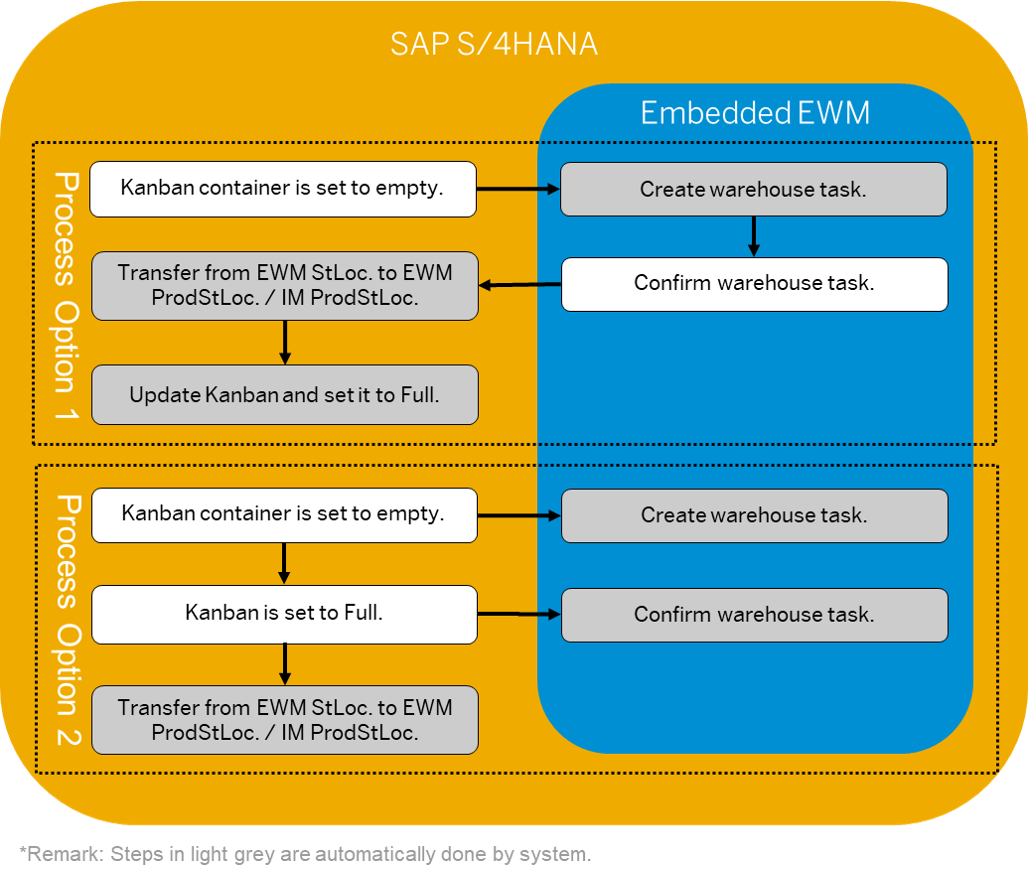

However, I want to point out two highlights. The first is the Production Supply with Kanban scenario via a direct Warehouse Task. This scenario is available beginning with the 1909 release for embedded SAP EWM. In this scenario, no production supply delivery is necessary, as the warehouse task is automatically created when a container is set to empty.

The other highlight scenario is JIT Supply to Production – Stock Transfer for JIT Call. This scenario is supported since the SAP S/4HANA 2020 release for embedded SAP EWM. Just as in the Kanban scenario described above, there is no outbound delivery / production supply delivery anymore, as an EWM stock transfer warehouse request is used instead. The warehouse task is created upon a JIT Call creation, with option to include wave management. Production supply for JIT Call is possible via distribution equipment.

SAP EWM Triggered Staging to Production

Unlike the case of ERP triggered staging, SAP EWM triggered staging has only 2 scenarios: Crate Part Production Supply and Advanced Production Supply using Production Material Request (PMR).

Of the two, Crate Part Production Supply scenario (supported since SAP EWM 7.0) only supports PSA managed under AFS storage location or separate EWM storage location. The details of this scenarios will not be outlined here, but you can read more about it in our linked document.

The other scenario (Advance Production Supply using PMR), is supported since EWM 9.2, and it introduced a new object in EWM called the Production Material Request. The PMR is a Warehouse Request for Production Integration, which can be used for staging & consumption for production but does not cover goods receipt. With the PMR it is also possible to do the staging for several items at one time, or even a partial quantity. With the PMR, new transactions and one report were introduced to facilitate Production Supply from EWM. One transaction is the “WDY_APPLICATION – Staging for Production” transaction. By using this transaction, users can get automatic quantity proposal for staging as well as directly create tasks for staging (no warehouse request needed).

With the report “/SCWM/STAGE – Schedule Staging for Production” warehouse operators can schedule to run the report regularly to create warehouse tasks automatically in background with quantity proposed. And finally, with another transaction “WDY_APPLICATION – Clear Production Supply Area” , operators can release stock reference from manufacturing order in case it is not needed anymore, as well as create warehouse tasks for moving materials back to storage from the PSA.

With the addition of the PMR, EWM becomes responsible for staging with more flexibility to optimize production supply. Staging for production can continue even if ERP is temporarily not available, and delivery documents are not used anymore, so that Less system resources are used and TCO is improved. For more details and screenshots of these scenarios, please refer to our linked document.

MES Triggered Staging to Production

In this scenario, a request to replenish stock can be triggered by SAP ME (supported since SAP EWM 9.2 and SAP ME 15.2, since SAP EWM 9.4 enhanced with external APIs for 3rd party MES). The request for single-order staging is automatically sent when the order is released or the SFC number is started or completed. The request contains only EWM-relevant components, either for all or just some specific steps. SAP EWM sends back a notification of staging confirmation automatically to SAP ME, and then the quantity of Inventory IDs are updated in SAP ME based on query of stock in the SAP EWM managed PSA (supported since SAP S/4HANA OP 1909 FPS1 and SAP ME 15.4 SP00). With this scenario, components staging is triggered when the production system determines a real demand. This pull method for staging serves production processes with limited space in the PSA better than a push method.

It is also possible to integrate SAP EWM with SAP Digital Manufacturing Cloud, since SAP S/4HANA OP 1909 FPS1 and SAP DMCe 2008 for below scenarios:

- Single Order Staging provides sending a request for the components to be staged for a specific order to a warehouse managed with SAP Extended Warehouse Management.

- Single Order Staging Confirmation allows thetransfer of stock change notification from SAP EWM to SAP DMCe when the warehouse task of component staging is confirmed (with SAP EWM Note 2944311).

Please note that Integration between SAP EWM and SAP DMCe has similar processes with the integration between SAP EWM and SAP ME.

Outlook

The journey towards an even deeper integration between production and warehousing is steadily and surely moving forward. Before I end today’s article I would like to share with you some news about the planned developments in the area of MES driven staging coming in this year’s SAP S/4HANA 2021 OP release. Below are some highlights of MES-Driven Staging process:

- Introduce a new staging method “Single Order Staging with Warehouse Request”

- Enable staging status synchronization between EWM and MES, with quantity updates in the Staging Request

- Enable users to check PSA capacity when creating Staging Tasks

- Restrict creating Staging Tasks from PMR

- Enable Wave Management for MES-Driven Staging

FIND OUT MORE!

There are more things to cover in the topic of Production Staging, and you can read about them in our “Staging for Production in SAP EWM – Overview” document.

For more details and technical information on our new releases, you can visit our “What’s New” viewer on help.sap.com.

For more information on upcoming developments, please visit our Roadmap Explorer.

For more information about SAP Extended Warehouse Management, please follow us on social media, our YouTube channel or our community pages:

SAP EWM Community:

https://www.sap.com/community/topics/extended-warehouse-management.html

SAP Digital Supply Chain Channel:

https://www.youtube.com/channel/UCELmE2CEAkcwqpBLnuZHufA

EWM LinkedIn Community:

https://www.linkedin.com/groups/1952257/

Release information and restrictions of embedded EWM on SAP S/4HANA 2020 and S/4HANA 2020 FPS01:

https://launchpad.support.sap.com/#/notes/2938306

Release information and restrictions of Decentralized EWM on SAP S/4HANA 2020 and S/4HANA 2020 FPS01:

https://launchpad.support.sap.com/#/notes/2938308

For a complete list of Q&A from the EWM community, please access this link:

https://answers.sap.com/tags/01200615320800000705

In case you do not find your specific question there, feel free to post your question via the following form:

https://answers.sap.com/questions/ask.html?primaryTagId=01200615320800000705

- SAP Managed Tags:

- SAP Extended Warehouse Management

Labels:

8 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

64 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Asset Performance Management Embedding Cumulocity IoT to Drive Innovations in IoT and AI in Supply Chain Management Blogs by SAP

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- Announcement: New integration platform in SAP Business Network for Logistics in Supply Chain Management Blogs by SAP

- Premium Hub CoE – DSC Knowledge Bits Series in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 8 | |

| 8 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 |