- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Use Case for Situation Handling – MRP Material Exc...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

kusiel_camargo

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-29-2021

6:08 AM

Introduction

As part of the SAP S/4HANA RIG team, we would like to provide some examples of Use Cases for Situation Handling that could be beneficial for your company. In the SAP Portal you can find the Use Cases available in your SAP S/4HANA version.

There are several activities that require our attention during the daily work. However, if we delay to action in some of them, we can cause subsequent impact in the supply-chain, or waste money by purchasing or producing unnecessary goods.

Situation Handling is a strategic SAP product, which brings a real tool to handle tasks which are difficult to follow-up, are time-consuming and on top of that, risky for business supply-chain when unattended.

In this blog, I will present to you how to monitor MRP Material Exceptions and act proactively when you receive the alerts via the Situation Handling tools.

Business scenario

Imagine that you are the production planner, and you have already a production order planned to supply the demand of a sales order. Now, by any reason, the sales order was cancelled, meaning that you don´t need to produce anymore. If you are not looking the Monitor Material Coverage or the Stock / Requirements List, you won´t cancel the production order on time.

1) How can Situation Handling help us?

The template MRP Material Exceptions is used by Situation Handling to inform specific members of your MRP organization automatically about exception messages that occurred during the MRP run for purchase orders or production orders that are no longer needed. For that, we can consider the conditions of the following exceptions:

- Cancel Process

- Excess Stock

2) How is Situation Handling set for this scenario?

You can check an example of this process in the SAP Best Practices Explorer, under the scope item J44 ( Chapters 2.4.2 - Prerequisite for Material Exception and 4.5 – Material Exception). There, you will see an example of exception handling for Purchase Requisitions. In this blog, I will show you an example when a sales order is cancelled.

2.1) Pre-requisites

You need the following SAP roles to set-up and test this scenario:

- SAP_BR_BUSINESS_PROCESS_SPEC - Business Process Specialist

- SAP_BR_BPC_EXPERT - Configuration Expert - Business Process Configuration

- SAP_BR_MATL_PLNR_EXT_PROC - Material Planner - External Procurement

- SAP_BR_PRODN_PLNR - Production Planner

You must have the users that will receive the notifications created as Employee Business Partners.

2.2) Defining the list of users to receive material exception notifications

Go to the app "Manage Teams and Responsibilities" and click on “Create”.

Then, select the Type “SMRPT” and press “Enter”.

Inform the Name, Global ID and change the status to “Enabled”.

In the Responsibility Definitions, you can assign the MRP Controller(s), Material(s) and Plant(s) allowed.

Next, verify the Team Owner and add the Team Members that will receive the notifications by clicking on “Create” > selecting the Employees > pressing “Go”.

Save.

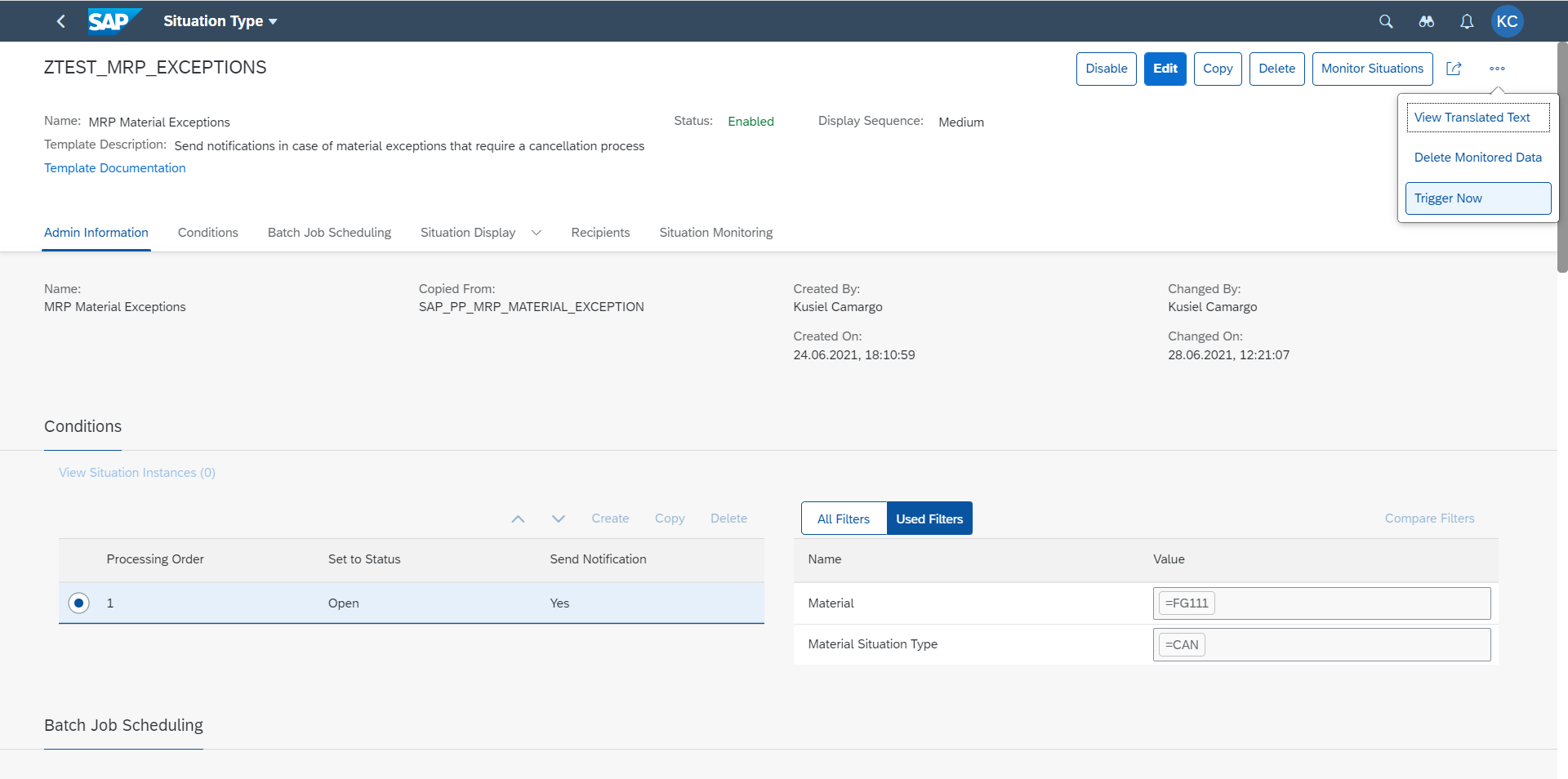

2.3) Defining your Situation type by copying the template MRP Material Exceptions

In the Fiori app “Manage situation types” , select the template SAP_PP_MRP_MATERIAL_EXCEPTION and click on “Copy”.

Now you are creating a New Situation Type, based on pre-fulfilled information copied from the template.

In the section “Admin information”, define an ID and a Name.

For the section “Conditions”, you will define the criteria to trigger the notification. The template proposes to send notifications with status “Open” and Material Situation Type = “CAN” (Cancel Process). In our example, I´ll restrict as well by Material.

But what is the situation type “Cancel Process”? It is the Exception Message “20 – Cancel Process” in the MD04 – Stock / Requirements List.

For Batch job scheduling, define when the system will check the documents and send the notification. In this case, it will be every day at 6 am Brazil.

TIP: if you´re-testing your scenario, you can trigger the job immediately after saving your situation type, clicking on “…” and “Trigger Now”.

In the section “Situation Display”, you can adjust the content of the message to be sent. For instance, you can add some variables in the Message Details by using “{ }”, or simply leave the text from the template.

Also, we recommend you flag that the system will aggregate several notifications in only one message.

In the section “Recipients”, review the Responsibility Definition and set the Member Function

In the section “Situation Monitoring”, flag “Monitor Instances” and save the Situation Type.

Click “Yes” to enable your Situation Type

3) How a Notification looks like?

Now, let´s execute the process to receive a notification.

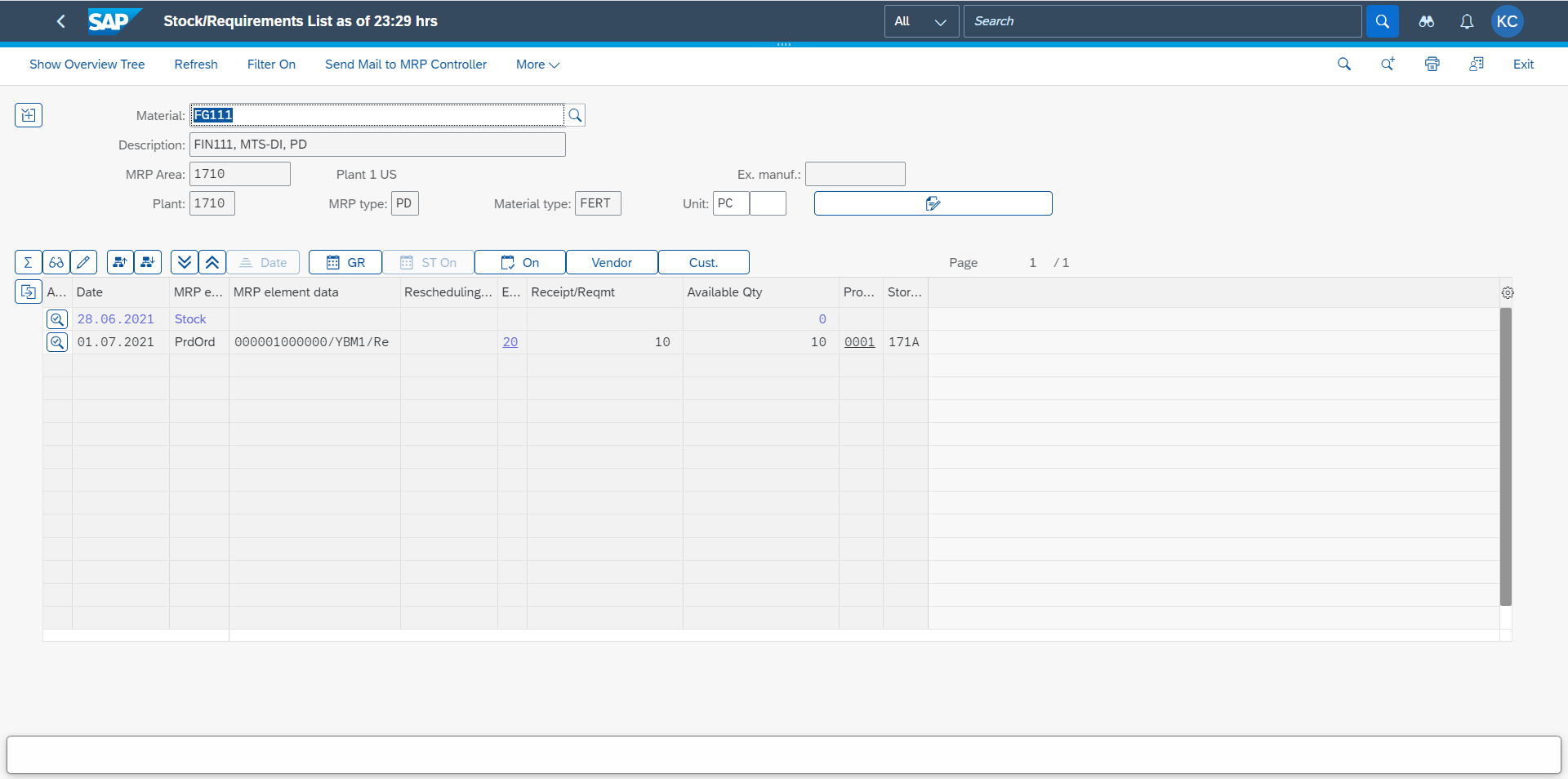

Initially, we have a Sales Order of 10 pieces with a Production Order created to supply this demand.

Then, by any reason, I cancel the Sales Order. For instance, enter in the app “Change Sales Order” > go to the tab “Item Detail” > select a “Reason for Rejection” > save the Sales Order.

You will notice that the Stock/ Requirements List has changed. Now we have a Production Order with the Material Exception “20” – Cancel Process.

Trigger the Job manually in the app “Manage Situation Type” or wait for the automatic daily execution according to the date / time you defined.

Once the Job is triggered, the employees assigned will receive a notification on the top right of their Fiori Launchpad screen.

Click on the icon and check the notification message.

You can click directly in the message and the system will take you to the app “Manage Material Coverage” (For Make-to-order scenarios, we need to go to the app “Monitor Material Coverage – Net and Individual Segments (Version 2)”, select the material and click on “Manage Materials”).

In the “Stock/ Requirements List” section, you will see a “trash can” icon in the column “Rescheduling”, for cancelling the Production Order.

Click on the “trash can” icon.

Click on “Yes” to confirm the Technical Completion of the Order.

There is no Production Order anymore in the Stock/ Requirements List.

You can click on “Close Situation” > select “Resolved” and click on “Confirm” to close this notification.

Conclusion

I hope you have learned about how SAP Situation Handling – MRP Material Exception can help you to monitor the supply-chain changes and react proactively. If you are interested to learn more about Situation Handling in the SAP S/4HANA, I suggest you the following blogs created by the SAP S/4HANA RIG team:

- SAP Fiori for SAP S/4HANA – Getting started with SAP Situation Handling

- Situation Handling: Use Case – Confirmation is Overdue for PR Item

- Situation Handling – Case Invoice Skipped in Payment Advice

Additionally, there are some very nice demos in the openSAP portal:

- openSAP Microlearning – Situation Handling for Physical Inventory Counting

- openSAP course s4h21 - Delivering Value with Intelligent Innovations in SAP S/4HANA – Unit 3

You’ll find much more on our SAP Fiori for SAP S/4HANA wiki

Other helpful links:

- See all questions and answers about SAP Fiori for SAP S/4HANA

- Follow SAP Fiori for SAP S/4HANAfor more blogs and updates

- Ask a Question about SAP Fiori for SAP S/4HANA

- Visit your community topic page for SAP Fiori

Please, let us know your comments. If you have any questions, we encourage you to post into the Q&A are using the Tags SAP S/4HANA, SAP Situation Handling and S/4HANA RIG and we will try to answer them as soon as possible.

Thank you!

Brought to you by the SAP S/4HANA RIG team.

- SAP Managed Tags:

- SAP Fiori,

- SAP S/4HANA,

- SAP Supply Chain Management,

- MAN (Manufacturing),

- SAP S/4HANA Private Cloud

Labels:

10 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

155 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- Collective processing of PR's generated by MRP in S4 Hana Public Cloud in Enterprise Resource Planning Q&A

- How to set BOM when splitting material codes from different suppliers for the same material in Enterprise Resource Planning Q&A

- Dynamizing Material Specifications and Inspection Plans in SAP in Enterprise Resource Planning Q&A

- Introducing the market standard of electronic invoicing for the United States in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 8 | |

| 7 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |