- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Multi Resource Scheduling in S/4 HANA ePPDS

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-03-2021

1:45 PM

Multi Resource Scheduling Heuristics in S/4 HANA

Purpose:

The purpose of this document is, How to reduce the total lead time of the multiple Orders loaded on the same Resource, with the same Start Date using the most suitable Heuristics in PPDS. You can use this algorithm(FM: /SAPAPO/HEU_MULTIRES_SCHED) to switch modes and sources of supply according to defined time blocks, to keep the receipts as close to the required date as possible.

Configuration Data

Activate the Business function

Using the Transaction: SFW5, Need to activate the below Business function SCM_APO_PPDS_PI

Copy the Multi Resource Heuristics

Copy the Multi Resource Heuristics  Create Master Data

Create Master DataThe below scenario is based on the Master data Finished Material: PPDSFIN1 Raw Materials: PPDSR1 & PPDS R2. Create BOM for the Finished material : PPDSFIN1

Work Centres: PPDSWC1, PPDSWC2, PPDSWC3 (Maintained as Modes in PDS) .

Create Routing for the FG Material, with Operation details maintained with Classification.

Create the Production Version Creation Product Data structure

Create Material Master

Material Master for all the required Materials like, FG, & Raw Materials can be created using Transaction Code: MM01. Make sure, for these Materials Advanced Planning Check, activated & necessary filed values maintained in the Advanced Planning.

Create BOM

Follow standard steps for creating BOM for the FG Material using the T Code: CS01

Create the Work Centres using the T Code CR01

Activate the Advanced Planning & also maintain the APO Resource Settings.

Maintain the Classification, for Identifying the Alternate Resources

Maintain the same for all the rest of the alternate Resources like PPDSWC2 & PPDSWC3

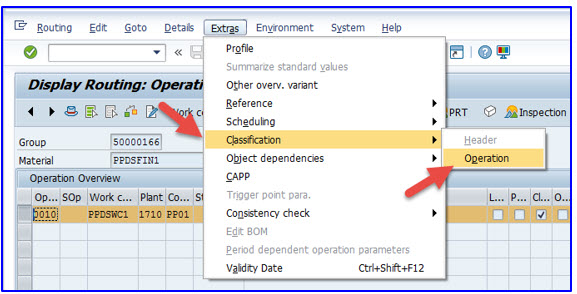

Create the Routing using the T Code CA01

Follow the standard stapes to create the Routing for the FG Material

Maintain the Classification at the Operation Level, with Class Type: 19 & assign the Class as shown below, with Priority as the Characteristic

Create Production Version

Follow the standard steps for creating the Production Version

Production Version is nothing but the Combination of BOM & Routing

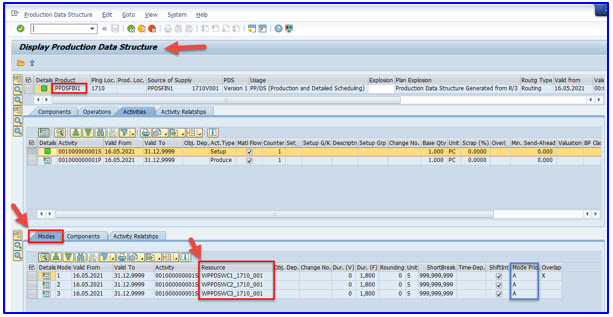

Create Production Data Structure

T Code: CURTOADV_CREATE

Create the Production Data Structure for the Finished Product in the Plant 1710

Once created the Production Data Structure, you can view/display the same using the

T Code: /SAPAPO/CURTO_SIMU (For the Finished Material: PPDSFIN1)

*** Make sure, all the Alternate Resources data is visible in the Modes

*** Make sure, all the Alternate Resources data is visible in the ModesExecute the below Transaction Steps

Create the Planned Orders in the Product View of the FG Material

Using the T Code: /SAPAPO/RRP3.

Create Multiple Planned orders, with same Start/Completion Date & with the smaller Lot size to get completed within the Day (Each order will take Less than 8H)

Take a look of the below Example, Planned Order with Order Qty : 4 are created with the same Start/Completion Date

**Make sure, all the Orders have the smaller Lot sizes

**Make sure, all the Orders have the smaller Lot sizesExecute the Heuristics I the Detailed Scheduling Board.

T Code : /SAPAPO/CDPS0

Maintain the Heuristic Profile in the Profile details

Look at this Video, to visualize the Effect of the Multi Resource Scheduling Heuristics

Hope this helps You in understanding the Concept of Multi Resource Scheduling.

Thanks A Lot for all Your kind feedback/comments.

Best Regards : Raja Sekhara Reddy Bannuru

Useful Links : https://wiki.scn.sap.com/wiki/display/SCM/Scenario+-+Run+Heuristic+SAP_MULT_SCH+in+PPDS+Planning+Boa...

- SAP Managed Tags:

- SCM APO Production Planning and Detailed Scheduling (PP/DS)

4 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- Keep Innovating with SAP Digital Manufacturing for Supply Chain - What's New in the 2402 Release in Supply Chain Management Blogs by SAP

- A day in the life of Sarah, a Production Supervisor using SAP Digital Manufacturing in Supply Chain Management Blogs by SAP

- What's new in SAP S/4HANA Asset Management for resource scheduling in Supply Chain Management Blogs by SAP

- Transforming Cell Gene Therapy Operations: The Power of Integrated Scheduling and Resource Planning Systems in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |