- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Problem solving process by using 8D methodology in...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member65

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-26-2021

5:39 PM

This blog explains about one of the new features from QM module i.e., “Problem solving process through 8D methodology”, Which is available in in S/4 HANA 1909 and S/4 HANA 2020 as well.

When we implement QM module for automobile industry, the most common ask from business is to map 8D methodology in SAP. Since we do not have direct solution in standard SAP either we do custom development or we do work around by defining tasks and activities in quality notifications. Now SAP came up with feature called “Non-conformance management” which deals with defects recording and investigation for that defect either through traditional Quality notifications or with 8D methodology.

What is 8D methodology?

The eight disciplines (8D) model is one of the problem solving approach typically employed by quality engineers. It is most used by the automotive industry however it has been successfully applied in healthcare, retail, finance, government and manufacturing.

The purpose of the 8D methodology is to identify, correct, and eliminate recurring problems, making it useful in product and process improvement. The 8D problem solving model establishes a permanent corrective action based on statistical analysis of the problem and focuses on the origin of the problem by determining its root causes. Although it originally comprised eight stages, or disciplines, the eight disciplines system was later augmented by an initial planning stage.

How to use 8D methodology?

How 8D methodology works in S/4 HANA?

When any defect identified by Quality technician or Quality engineer, they will create defect by using “Process defects” fiori app and upload the relevant documents and picture if required.

In this app, we have option to two option for problem solving for the created defect under “problem solving process tab” Here you can choose one of the below options.

Once you select 8D methodology, you can get below format as like legacy 8D format. Here you can eight disciplines. Initially all tasks will have status “Not started”. Once you start the task you can change the status to “In process” and then you can change to “complete” once it gets completed.

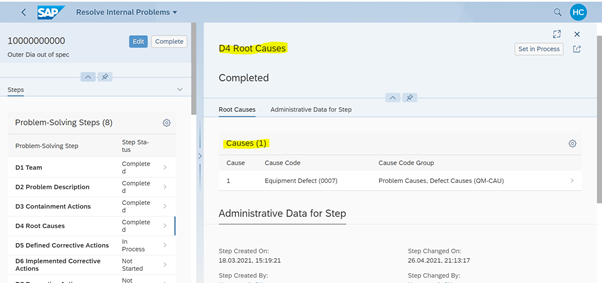

During this process, you can define the root cause in D4, can define task for corrective action with respect to root cause in D5, can implement task and can be assigned, which was defined in earlier stage in D6 and can perform prevent actions in D7.

Once step get completed, update the status as “Completed” so that status can be monitored. By this way you can perform 8D steps by using standard SAP functionality.

This functionality available only in fiori that means this feature is not available in GUI. By using this functionality, we can map 8D methodology requirement in SAP without any custom development or without any work arounds.

Thanks & Regards

Hanumantharao.C

SME-PP/QM

When we implement QM module for automobile industry, the most common ask from business is to map 8D methodology in SAP. Since we do not have direct solution in standard SAP either we do custom development or we do work around by defining tasks and activities in quality notifications. Now SAP came up with feature called “Non-conformance management” which deals with defects recording and investigation for that defect either through traditional Quality notifications or with 8D methodology.

What is 8D methodology?

The eight disciplines (8D) model is one of the problem solving approach typically employed by quality engineers. It is most used by the automotive industry however it has been successfully applied in healthcare, retail, finance, government and manufacturing.

The purpose of the 8D methodology is to identify, correct, and eliminate recurring problems, making it useful in product and process improvement. The 8D problem solving model establishes a permanent corrective action based on statistical analysis of the problem and focuses on the origin of the problem by determining its root causes. Although it originally comprised eight stages, or disciplines, the eight disciplines system was later augmented by an initial planning stage.

How to use 8D methodology?

- D1: Use a team - Select and establish a team of people with product/process knowledge.

- D2: Define and describe the problem- Specify the problem by identifying in quantifiable terms the who, what, where, when, why, how, and how many (5W2H) for the problem.

- D3: Develop interim containment plan; implement and verify interim actions- Define and implement containment actions to isolate the problem from any customer.

- D4: Determine, identify, and verify root causes and escape points- Identify all applicable causes that could explain why the problem occurred. Also identify why the problem was not noticed at the time it occurred by using 5 whys and cause and effect diagram to map causes against the effect or problem identified.

- D5: Choose and verify permanent corrections (PCs) for problem/nonconformity- Through preproduction programs, quantitatively confirm that the selected correction will resolve the problem for the customer.

- D6: Implement and validate corrective actions- Define and implement the best corrective actions (CA).

- D7: Take preventive measures- Modify the management systems, operation systems, practices, and procedures to prevent recurrence of this and all similar problems.

- D8: Congratulate your team- Recognize the collective efforts of the team. The team needs to be formally thanked by the organization.

How 8D methodology works in S/4 HANA?

When any defect identified by Quality technician or Quality engineer, they will create defect by using “Process defects” fiori app and upload the relevant documents and picture if required.

In this app, we have option to two option for problem solving for the created defect under “problem solving process tab” Here you can choose one of the below options.

- Quality tasks

- 8D methodology.

Once you select 8D methodology, you can get below format as like legacy 8D format. Here you can eight disciplines. Initially all tasks will have status “Not started”. Once you start the task you can change the status to “In process” and then you can change to “complete” once it gets completed.

During this process, you can define the root cause in D4, can define task for corrective action with respect to root cause in D5, can implement task and can be assigned, which was defined in earlier stage in D6 and can perform prevent actions in D7.

Once step get completed, update the status as “Completed” so that status can be monitored. By this way you can perform 8D steps by using standard SAP functionality.

This functionality available only in fiori that means this feature is not available in GUI. By using this functionality, we can map 8D methodology requirement in SAP without any custom development or without any work arounds.

Thanks & Regards

Hanumantharao.C

SME-PP/QM

- SAP Managed Tags:

- MAN (Manufacturing),

- PLM Quality Management (QM)

6 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Customizing

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

Ledger Combinations in SAP

1 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

S4HANACloud audit

1 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

Time Management

1 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- SAP S/4HANA Data Migration and Master Data Management Best Practices with SAP BTP in Enterprise Resource Planning Blogs by SAP

- SAP Activate methodology Prepare and Explore phases in the context of SAFe. in Enterprise Resource Planning Blogs by SAP

- Jumpstart your cloud ERP journey with guided enablement in RISE with SAP Methodology in Enterprise Resource Planning Blogs by SAP

- Working with SAFe Epics in the SAP Activate Discover phase in Enterprise Resource Planning Blogs by SAP

- Update of the SAP Activate Roadmap for SAP S/4HANA (on prem) upgrades with the Clean Core Strategy in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 11 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 |