- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Synchronous Goods Receipt for Kanban: Kanban for i...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Synchronous Goods Receipt for Kanban:-

With this feature, synchronous goods receipt with the Kanban replenishment strategy In-House can be posted with Production using the control type ''Working with Production Orders for goods receipt from discrete manufacturing directly to the bin of the production supply area (PSA).

Diagram from SAP document to understand synchronous goods movement.

Synchronous goods movements are also supported for the following Kanban strategies:

Summarized JIT call (Kanban) with goods receipt from vendor directly to PSA bin.

Kanban replenishment strategy In-House Production using the control type Processing with Planned Orders and Cost Collector for goods receipt from repetitive manufacturing directly to the PSA bin

For this blog, Kanban Inhouse '0006' Replenishment strategy has been taken.

Step 1:Kanban to empty →creation of production order

System will create a Production order emptying Kanban Card,

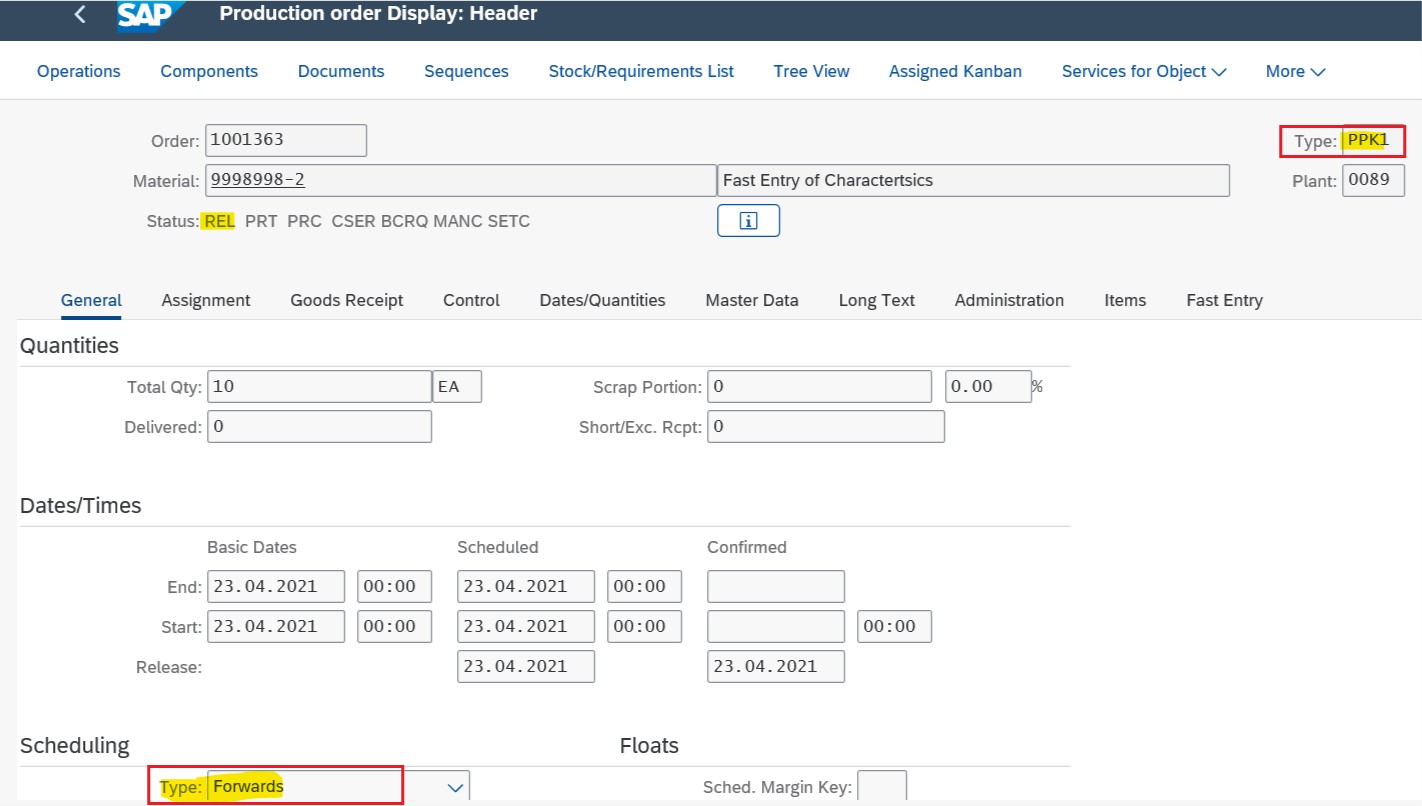

Configure all PP production order process for Auto Order release, synchronous goods posting from production scheduling profile and control cycle. Use SAP standard order type for Kanban PPK1 with Forward scheduling.

Step 2: Confirmation and GR of prod. order →Kanban to full

On successful Kanban confirmation, Card signal changes from Empty to Full.

System created a material document associated with Production order.

Production Order Completed.

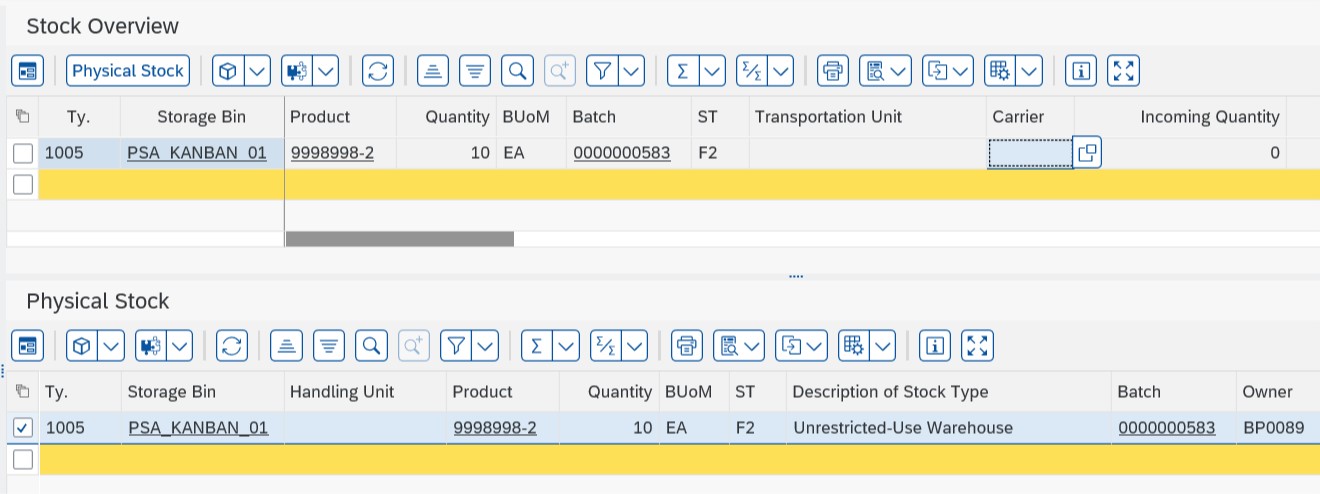

Stock Updated.

Warehouse Task created & Confirmed automatically.

Customization Involved.

Effects on Existing Data

The system determines the goods receipt bin from the Kanban control cycle.

Effects on Customizing

Activate synchronous goods receipt in the production scheduling profile assigned to the Kanban material:

In Customizing for Production under Shop Floor Control Master Data Define Production Scheduling Profile for Discrete Manufacturing

- Set up several options for control of 'Automatic Warehouse Task Creation'' at storage type level or WPT level. Also determination of WPT with synchronous posting without document type and Item type

Thanks for reading through, I would write more stuff on EWM Manufacturing integration on S/4 HANA 2020 Embedded EWM.

Reference:https://help.sap.com/doc/474a13c5e9964c849c3a14d6c04339b5/100/en-US/363e55b4cd0a400b86f994b282cd4f7f...

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- How strikes affect the supply chain in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

- Practical Insights into New Features of SAP EWM in S/4HANA 2023 in Supply Chain Management Blogs by Members

- Early Stock Simulation for PMR documents Posting- Consumption & Consumption Reversal in Supply Chain Management Blogs by SAP

- Cracking the Easter Supply Chain: Balancing Demand, Sustainability and Chocolate Eggs in Supply Chain Management Blogs by SAP

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |