- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Asset Management in SAP S/4HANA Cloud 2102

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Maintenance Operations

Resource Scheduling

Business Processes

Maintenance Operations

Intelligent Scenario for Damage Code Prediction

Let's start directly with the most intelligent release highlight in Maintenance Management, the use of Machine Learning capabilities for damage code prediction.

This feature enables you to view appropriate damage code as part of the value help. You can view the proposed damaged code on an existing maintenance order. The damage code suggestions are based on the information available for the notification such as notification type, description, plant, functional location, equipment number and long text.

In the following video, a maintenance technician or supervisor opens the My Maintenance Jobs app, searches for maintenance orders which are ready for execution, opens the details of a particular order, and adds a new malfunction. For this purpose it's necessary to maintain the malfunction details. When the user opens the value help for the damage code on the malfunction details screen, the system automatically proposes a damage code specifying the Confidence calculated by the machine learning model. Then the user has the free choice to accept the proposal or choose any other damage code. The business benefits are obvious:

- Decrease the time needed to assign the correct damage code

- Improve your data quality for later breakdown analysis

Video 1: Use Machine Learning algorithms to propose damage code when adding a malfunction in a maintenance order.

Configuring Intelligent Scenario for Damage Code Prediction

Watch the next video where an analytics specialist trains and activates the model so that the system proposes damage code on an existing work order. The procedure to activate the intelligent scenario for damage code prediction consist of the following steps:

- Select Intelligent Scenario Management tile.

- Select a Package under Intelligent Scenarios table.

- Select EAM_ML_ORDER_DAMAGE_CODE package.

- Select Model and click Train to create a model version.

- Select Model Version and click Activate.

Video 2: Train and activate the intelligent scenario model for damage code prediction

Technically the damage code prediction is based on a random forest algorithm.

Maintenance Request

Technical Object Search based on Functional Location Hierarchy

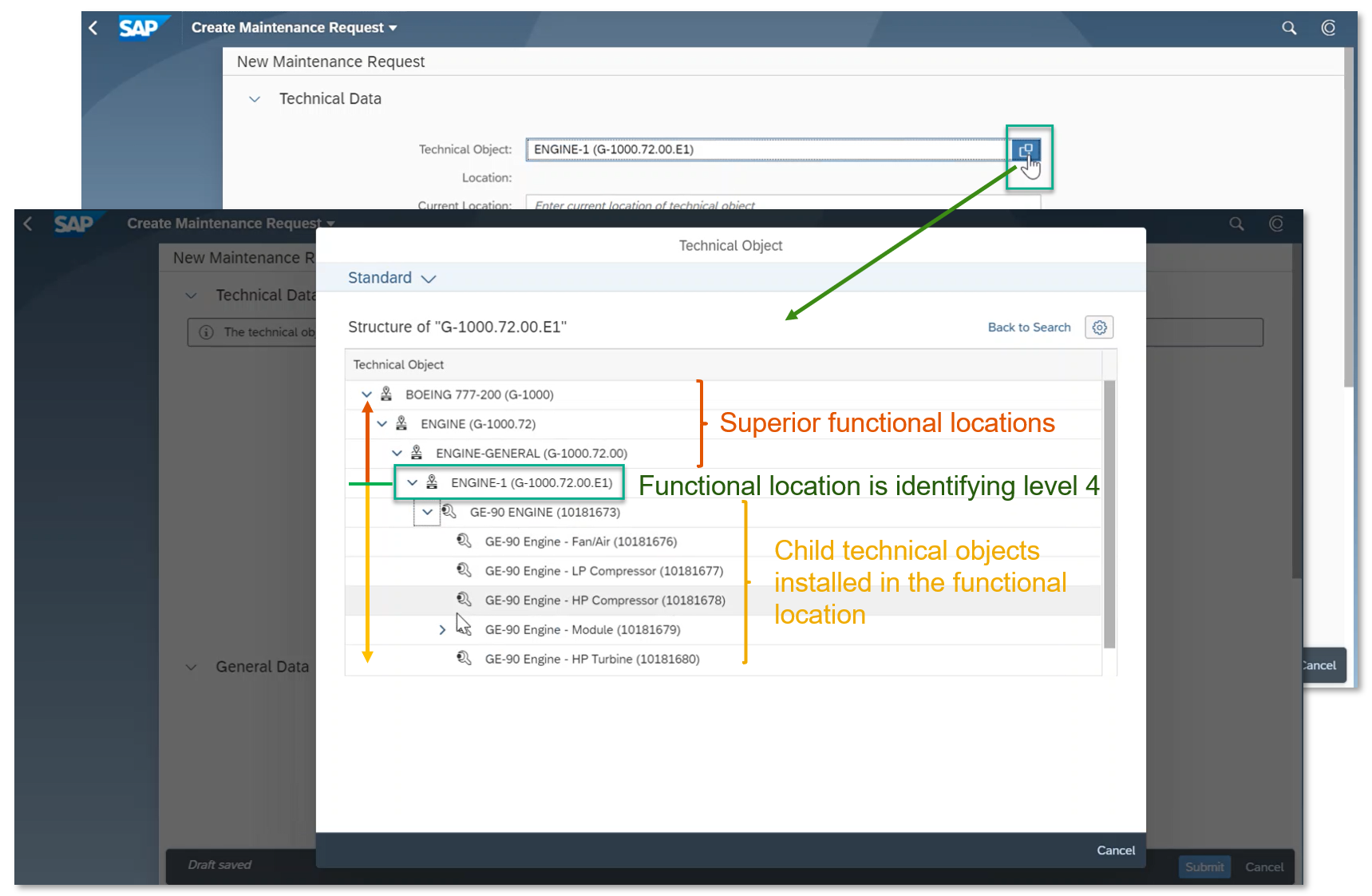

In the Create Maintenance Request app, you can now view hierarchy of functional location and equipment. If the functional location is an identifying level, complete hierarchy of a technical object is displayed which include superior functional locations and child technical objects. These are technical objects that are installed in the functional location. If it is not an identifying level it will show only superior functional location and not child technical objects.

Let me illustrate the logic with an example:

To enable the ‘Search’ with functional location hierarchy with its sub functional locations and installed equipment, a setting in the self-service configuration UI (SSCUI) is necessary. For this purpose, the business process configuration expert (role SAP_BR_BPC_EXPERT) opens the Manage Your Solution app and selects the configuration step Create Structure Indication for Reference Locations/Functional Locations in application area Asset Management, sub application area Maintenance Management and item name Order Processing.

In our example the configuration to define the structure indicator is maintained with the following setting: The 2nd Identifying Level is equal 4.

Fig. 1: 'Manage Your Solution' app - configuration step 'Create Structure Indication for Reference Locations/Functional Locations'

If the maintenance technician enters a functional location which is the identifying level 4, the value help displays the complete hierarchy of the technical object which include the three superior functional locations and the child technical objects that are installed in the functional location:

Fig. 2: Create Maintenance Request app - Technical Object Search based on Functional Location Hierarchy

For comparison, if the technician enters the name a functional location in the hierarchy which does not meet the identifying level, the value help shows only the superior functional location and not child technical objects.

Fig. 3: Create Maintenance Request app - Technical Object Search based on Functional Location Hierarchy

Quick view

In the My Maintenance Requests and Screen Maintenance Requests apps, you can use quick view for technical object and maintenance order and navigate to corresponding object pages for additional details.

Fig. 4: Quick view for technical object and maintenance order as well as navigation to corresponding object pages

Phase and sub phase

In the My Maintenance Requests and Screen Maintenance Requests apps, you can view the phase and sub phase of a maintenance request.

Fig. 5: View the phase and sub phase of a maintenance request

Phase control code

Configuration Settings

You can block the transition of an order or an operation from one phase to another phase using phase control codes.

Fig. 6: Typical use case: Set and reset phase control code to block a particular process phase for a while

For this purpose you can setup the phase control code for maintenance orders with Authorization Keys and System Statuses.

The configuration step Define Phase Control Code for Maintenance Orders is available in the Manage Your Solution app if you select the application area Asset Management, sub application area Maintenance Management and item name Order Processing:

Fig. 7: 'Manage Your Solution' app - configuration step 'Define Phase Control Code for Maintenance Orders'

You can set and reset a phase control code if you navigate to the Phase Control tab on the Maintenance Order detail page using the app Find Maintenance Order.

Fig. 8: Add and deactivate a phase control code on a maintenance order

API for Maintenance Tasklist

The inbound OData service Maintenance Tasklist enables external systems and other consumers to read, create and update maintenance task list data through API calls.

One can use it to access data from general, equipment or functional location task list data. The service makes maintenance task list data available through its header, operation, maintenance package, and operation relationship entities. You can also query each entity to retrieve the corresponding business data.

(back to top)

Resource Scheduling

Maintenance Scheduling Board - Gantt Chart

We've made several changes in the Maintenance Scheduling Board app. For example, you can now move order operations directly in the chart using drag and drop and show Must start on constraints for order operations.

Drag and Drop of Operations

You can now use drag and drop to move individual order operations in the chart. The app adjusts the start time to the nearest hour to the drop position.

Fig. 9: Maintenance Scheduling Board app - Drag and Drop of Operations

To help you better distinguish between implicit and explicit relationships, implicit relationships are now indicated by a dashed gray line instead of a solid gray line. Remember: To show relationships in the chart, you must first enable the relevant settings.

New Chart Settings

Two new settings allow you to show additional information in the chart:

● Show Non-Working Times: You can show the times when a work center is closed. In the chart, non-working times are visualized as light gray vertical bands.

● Show 'Must-Start On' Constraints: For order operations that have a Must start on constraint, you can show the date and time when the operation must start. In the chart, the constraint is visualized by a vertical line at the beginning of the operation bar.

Fig. 10: Maintenance Scheduling Board app - New chart settings for showing Non-Working Times and visualization of restrictions (Must-Start On Constraints)

Manage Work Center Utilization

Cross-App Navigation

If you have the required authorization, you can now open the Change Work Center app from the Change Work Center Capacity dialog. To open the app, just click the link for the work center name as shown in the figure.

Fig. 11: Manage Work Center Utilization app - Open the Change Work Center app from the Change Work Center Capacity dialog via cross-app navigation

The short video below shows the cross-app navigation. A maintenance planner or supervisor who has been assigned business catalog Production (Discrete) - Process Engineering (SAP_SCM_BC_PROC_ENG_MC) opens the Change Work Center Capacity dialog within the Manage Work Center Utilization app and navigates to the Change Work Center app by clicking the link for the work center name.

Fig. 12: Cross-app navigation from the Manage Work Center Utilization app to the Change Work Center app

Additional fields available now

The following attributes are now available as filters in the filter bar and as table columns on the Maintenance Order Operations tab within the Manage Work Center Utilization app:

- Order Phase Control

- Operation Phase Control

- Technical Object (Operation)

- Functional Location (Operation)

- Equipment (Operation)

- System Condition (Operation)

Fig. 13: Manage Work Center Utilization app - Field Operation Phase Control is now available as filter in the filter bar and as table column on the Maintenance Order Operations tab

(back to top)

Business Processes

Although this blog is focused on SAP S/4HANA Cloud let us conclude by expanding our view of products in the environment.

For this purpose, open the SAP API Business Hub, click on Business Processes in the navigation pane on the left side and expand the overview of business processes by choosing the View more option.

Fig. 14: SAP API Business Hub - Business Processes

Acquire to Decommission (Hybrid)

Click on the tile Acquire to Decommission (Hybrid) to review the process flow of the business process.

Fig. 15: SAP API Business Hub - Business Process 'Acquire to Decommission'

For instance, click on the process flow step Monitor asset and events. The detailed view on this step shows how the products SAP S/4HANA, SAP Predictive Asset Insights (formerly known as SAP Predictive Maintenance and Service) and SAP Internet of Things interact.

Fig. 16: Business process 'Acquire to Decommission (Hybrid)' - details of step 'Monitor asset and events'

This process flow leads me to an interesting innovation in SAP Predictive Asset Insights which is an Internet of Things (IoT) application that helps you to avoid costly disruptions by predicting equipment malfunctions before they happen by processing huge volumes of information technology (IT) and operational technology (OT) data using sophisticated machine learning algorithms.

SAP Predictive Asset Insights 2.0

The Alert Analysis Tool as part of SAP Predictive Asset Insights displays a list of the current alerts that are triggered by equipment events or rules defined for sensor data and health scores. Alerts calculated from sensor data or health scores give you information about the issues your equipment or functional locations (technical objects) are experiencing. Within the alert analysis tool, you can display an alert page that contains the alert details and additional information. The information provided helps you to decide on prescriptive maintenance and helps to identify potential actions to be taken for the incoming alerts. With the 2102 release, customers are able to customize the process for handling alerts with additional attributes. For this purpose, alert extensibility supports

- Definition of custom alert attributes

- Manual population of custom alert attributes

- Display of custom alert attributes in alert lists and as part of detailed alert information

The animated figure below shows how an administrator configures a required custom field with the name "Custom Status" to alert by calling a public API. After this configuration step the user opens the Explorer app and adds the custom field as a new column to the alert list.

Fig. 17: Configure a new custom field to alert by calling a public API

The next figure shows a test scenario in which the custom field is populated via API call with the value "Send from Machine". Than the information sent from source is displayed in the custom field on the Explorer app.

Fig. 18: The information sent from source is displayed in the custom field on the Explorer app.

(back to top)

Thanks for reading this blog post. Stay tuned!

You will find a collection of my SAP S/4HANA Cloud release blogs here:

For more information on SAP S/4HANA Cloud, check out the following links:

- SAP S/4HANA Cloud release info: http://www.sap.com/s4-cloudrelease

- Latest SAP S/4HANA Cloud Release Blogs here and previous release highlights here

- Product videos on our SAP S/4HANA Cloud and SAP S/4HANA YouTube playlist

- SAP S/4HANA PSCC Digital Enablement Wheel here

- Early Release Webinar Series here

- Inside SAP S/4HANA Podcast here

- SAP S/4HANA Microlearning (OP/CL) – The ultimate collection blog

- openSAP Microlearnings for SAP S/4HANA for Supply Chain here

- Best practices for SAP S/4HANA Cloud here

- SAP S/4HANA Cloud Customer Community for Manufacturing here

- Feature Scope Description here

- Help Portal Product Page here

- Implementation Portal here

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

155 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

- CDS view Required - S4Hana Public Cloud MD04 - stock functionality (released) in Enterprise Resource Planning Q&A

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Improvements to manage treasury position in SAP Treasury and Risk Management in Enterprise Resource Planning Blogs by SAP

- How to find field technical details in S4HANA Cloud solution in Enterprise Resource Planning Q&A

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 8 | |

| 7 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |