- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Flexible bin concept in EWM

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

martinprokop

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-08-2021

5:01 PM

Introduction

One of putaway strategies in standard EWM is called "Storage Behavior: Flexible bins". The documentation for this feature describes the customizing steps nicely. What is not described there, is the main idea, the concept of this feature. This is, what I try to formulate bellow.

Flexible Bin Concept

The standard concept is working with a network of cells of same size (x & y dimension). This network can be used to create new flexible bins of different sizes, consisting from 1-n adjacent cells. It is obvious, such bins are more likely directly on the floor, in a warehouse area without any fixed racking structures.

A bin can for example be named as combination of

- prefix (area)

- XY coordinates of lower left end cell of the bin

- XY coordinates of upper right end cell of the bin

"A1-0302-0303" reaches from cell (X = 03, Y = 02) to cell (X = 03, Y = 03) in the area A1

Network of cells forming flexible bins

You define the pattern for these bins in transaction /SCWM/FLEXBINAREA:

These bins are created either:

1. during confirmation of a WT (bin in a specific format is entered in NLPLA)

2. by a Badi during creation of a WT

Option 1 needs to create primarily a putaway WT without specific NLPLA bin (see "WT Generic" in customizing of Storage type).

However, it is hardly possible the user could correctly specify the name of the newly created bin using above described logic (specifying lower left and upper right cell of the bin he's just used for putaway...)

Confirmation of WT with manually entered flexible bin

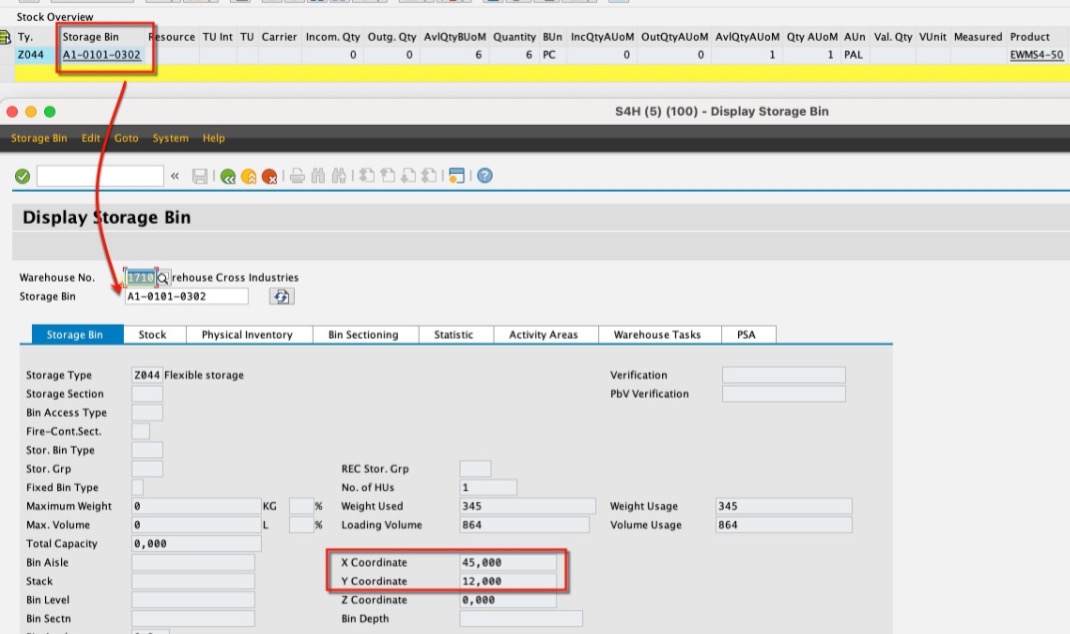

New flexible bin created with coordinates of the lower left cell

Option 2 is more likely to be used. The logic in the example code for Badi /SCWM/EX_CORE_DYNBIN_DESTBIN tries to determine the next available cell in the network, and to find how many adjacent cells are needed for putaway of the certain WT item.

It is only pity the number of cells is determined on hand of length and width of the basic UoM of the product being putaway(...), instead of using of measurments of the HU for example. But, it is only an example code, of course. You are free to engage with your own logic.

Determination of the new bin size in number of cells

Finally, Badi composes the name of newly assigned bin (e.g. "A1-0302-0303") and WT is created with this target bin already.

It is, again, a bit tricky to imagine, how this new bin code will be confirmed on RF... There will be probably no bin label to be scanned in this case. More likely in this case the destination bin will not be required in RF (by customizing of confirmation control).

Flexible bins are automatically deleted

when being emptied, at least in standard. Freed cells are available for composition of new bins again.

Addtional hints

There is a bit mismatch in terminology around this topic. Although "Flexible bins" is used in the end-user interface, the main class is /SCWM/CL_DYNBIN and also in the code is mostly referred as "Dynamic bins".

This can lead to mistakes, as the term "Dynamic bins" was rather used in WM, in case of bins in interim storage types 9xx, which vere automatically created and deleted by system. These bins, however, were used only technically to distinguish for example original Purchase order number, but did not represent a physical area in the warehouse.

Conclusion

Main concept of "Storage behavior: Flexible bin" is clarified and possible use-cases are presented.

- SAP Managed Tags:

- EWM - Basic Functions

5 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- Drive productivity, safely and sustainably, with SAP manufacturing solutions in Supply Chain Management Blogs by SAP

- How strikes affect the supply chain in Supply Chain Management Blogs by SAP

- RISE with SAP advanced PLM package in Supply Chain Management Blogs by SAP

- Through MRP run, Flexible Workflow for Purchase Requisition is not triggerring in Supply Chain Management Q&A

- Advanced Shipping and Receiving – Go-live support insights in bgRFC based EWM-TM integration in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |