- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Increasing Reliability with Supply Protection

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-22-2021

2:55 PM

Almost every company wants to be reliable for its customers and to sell everything without leftovers, but it also wants to sell everything with a high margin. Supply protection (SUP) can help you to avoid shortages.

In many cases, companies want to prevent that customers who are considered as less important, order too much so that there is not enough stock left for the customers of higher priority. This is very typical in the fashion industry. Here, wholesale customers order at the very beginning of the season. Channels with higher margins or higher strategic importance (for example, e-commerce or the own Retail stores) order later.

On the other hand, it is also intended to sell as much as possible if there is no shortage regarding the stock.

Supply protection works like a virtual demand reservation defined for a specific material-plant-combination. If there is a supply protection object defined, for example, for the e-commerce channel, every other demand element must respect these reserved quantities as a restriction. In other words, the available stock will be reduced virtually, and the less important demand can only be confirmed, if there is enough unrestricted stock left.

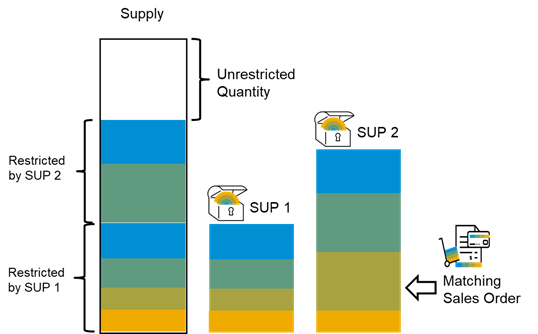

Within a supply protection object, you can define prioritized protection groups. Here, the logic works like this: Demand matching with a high priority protection group can ignore the protection for lower prioritized protection groups. Demand matching with a low priority protection group must respect the protection of higher or equal priority.

Prioritized protection is also called “vertical protection”, whereas the protection between different supply protection objects always works as mutual restriction with the complete protected quantities (independent, if the supply protection object consists of protection groups with different priorities).

Example:

Whenever a supply protection object has been activated, it will be considered in the logic of the product availability check (PAC) and restrict other demands. This is very important, especially if there is no easy way to get additional supply such as the example from the fashion industry.

Within a defined planning horizon, protection quantity can be defined for the different time buckets. You can divide a protection group in daily, weekly, monthly, or quarterly time buckets. You can, however, define only one time bucket.

Screen: Supply Protection Object

The advantage of time buckets is that they can expire over time. If there are time buckets defined for the peak season, the protected quantities will either be used (consumed by incoming orders / stock transport orders) or the protection can expire, if the groups for which the protection was defined, have not ordered the expected quantities. Expired protection frees quantities for other demands again.

If the end date of a time bucket has been passed, the protection expires. This frees again quantities for other customers. In other words, at the end of the season, it turns from a protected to a First-In First-Out (FIFO) principle.

It’s also possible to combine product allocation (PAL) together with supply protection. With product allocation you can define a limit for the demand element. So, a specific customer or any defined group (for example, a channel, or a market) cannot exceed a certain limit. With supply protection you can define a minimum quantity for this group, so that there is at least this quantity available for this customer group.

Incident component for clarifications: CA-ATP-SUP

SAP Note 2885961

SAP Help: Manage Supply Protection

Business Use Case

In many cases, companies want to prevent that customers who are considered as less important, order too much so that there is not enough stock left for the customers of higher priority. This is very typical in the fashion industry. Here, wholesale customers order at the very beginning of the season. Channels with higher margins or higher strategic importance (for example, e-commerce or the own Retail stores) order later.

On the other hand, it is also intended to sell as much as possible if there is no shortage regarding the stock.

How Does Supply Protection Work?

Supply protection works like a virtual demand reservation defined for a specific material-plant-combination. If there is a supply protection object defined, for example, for the e-commerce channel, every other demand element must respect these reserved quantities as a restriction. In other words, the available stock will be reduced virtually, and the less important demand can only be confirmed, if there is enough unrestricted stock left.

Within a supply protection object, you can define prioritized protection groups. Here, the logic works like this: Demand matching with a high priority protection group can ignore the protection for lower prioritized protection groups. Demand matching with a low priority protection group must respect the protection of higher or equal priority.

Prioritized protection is also called “vertical protection”, whereas the protection between different supply protection objects always works as mutual restriction with the complete protected quantities (independent, if the supply protection object consists of protection groups with different priorities).

Example:

Supply Protection

Whenever a supply protection object has been activated, it will be considered in the logic of the product availability check (PAC) and restrict other demands. This is very important, especially if there is no easy way to get additional supply such as the example from the fashion industry.

Within a defined planning horizon, protection quantity can be defined for the different time buckets. You can divide a protection group in daily, weekly, monthly, or quarterly time buckets. You can, however, define only one time bucket.

Screen: Supply Protection Object

The advantage of time buckets is that they can expire over time. If there are time buckets defined for the peak season, the protected quantities will either be used (consumed by incoming orders / stock transport orders) or the protection can expire, if the groups for which the protection was defined, have not ordered the expected quantities. Expired protection frees quantities for other demands again.

If the end date of a time bucket has been passed, the protection expires. This frees again quantities for other customers. In other words, at the end of the season, it turns from a protected to a First-In First-Out (FIFO) principle.

Supply Protection and Product Allocation

It’s also possible to combine product allocation (PAL) together with supply protection. With product allocation you can define a limit for the demand element. So, a specific customer or any defined group (for example, a channel, or a market) cannot exceed a certain limit. With supply protection you can define a minimum quantity for this group, so that there is at least this quantity available for this customer group.

Additional Information:

Incident component for clarifications: CA-ATP-SUP

SAP Note 2885961

SAP Community Blog:

- Manufacturing and Supply Chain in SAP S/4HANA Cloud 2102

- Supply Chain in SAP S/4HANA Cloud 2111

- Alerting Multiple Matches in Supply Protection by Using Situation Management

- Supply Protection in a Nutshell

SAP Help: Manage Supply Protection

- SAP Managed Tags:

- SAP S/4HANA for advanced ATP,

- SAP S/4HANA Public Cloud

Labels:

5 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

22 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

157 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,684 -

Product Updates

218 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- What You Need to Know: Security and Compliance when Moving to a Cloud ERP Solution in Enterprise Resource Planning Blogs by SAP

- Insights on Supply Protection using Temporary Assignment in Enterprise Resource Planning Blogs by SAP

- Join the Innovation Journey with SAP Enterprise Threat Detection, cloud edition in Enterprise Resource Planning Blogs by SAP

- Supply Protection In a Nutshell in Enterprise Resource Planning Blogs by SAP

- Restriction outside Planned Protection in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 13 | |

| 11 | |

| 10 | |

| 7 | |

| 7 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 |