- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Monday Knowledge Snippet (MKS) – 109 S/4HANA 2020 ...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member18

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-03-2020

6:11 AM

Today I would like to show a feature that actually links 2 already existing features together to create new options for end-to-end transportation planning. On the one hand we have the feature of location groupings, that can be considered during package building (see MKS94 for more details). On the other hand, we have Package Units introduced with TM 9.6 / S41909 (see MKS91). Remember, the purpose of PUs is to reflect actual packaging, that will only change on an exceptional basis and improve the input for the automated vehicle, scheduling and route planning.

Package Units could so far only be create early during Freight Unit Building, manually, or automatically using the feature ‘Create PU based on PB’ (Create Package Units based on Package Building). For the later, only the ‘Exclusive Package for Customer’ (MKS93) was considered. When the feature detected one or multiple Freight Units for the same customer having the indicator set, it created Package Units and assigned the Freight Units to it. The FUs going to other customers not having the indicator stayed untouched. All further planning happens based on the created PUs and the still unplanned FUs.

The automatic PU creation is also possible automatically using a background report (/SCMTMS/PLN_PB_FU_BGD). In addition, the PU creation can be added as a pre-processing step to automatic planning strategies (method VSR_CEPU).

It became clear quickly that the PUs are a powerful tool to improve and streamline the planning. Luckily, the feature to create them automatically was designed from the vey beginning having in mind that additional Freight Unit attributes could be a trigger to do so.

So let’s check how this evolved. I have a scenario with a location soft group represented by a location hierarchy. It contains two shopping malls each having 2 customer locations (shops, restaurants,…). A location soft group means for my scenario that I prefer all to be delivered items going to customers within a unique group on one or multiple separated pallets if the utilization is good enough (see MKS106) during consolidation package building. If the defined threshold is not fulfilled, I prefer the items to be packaged following a product grouping to enable easy search for the delivery person.

Nice feature to consider this during consolidation package building, but it would be even better to transfer those top level package fulfilling a utilization threshold into Package Units before calling the VSR optimizer.

Location Soft Group

I set the location hierarchy in the Package Building Profile.

In my planning session in the Transportation Cockpit I have multiple Freight Units going to customers within the shopping malls, but also FUs for customers outside.

And now I activate the new enhanced creation of PUs in the Planning Profile:

Here you now have the option to define a ‘Location Group Utilization Threshold’, a ‘BP Utilization Threshold’, and select a ‘Dimension for Utilization Threshold’. The first 2 are percentages and for the dimension you can select ‘Volume’, ‘Weight’, or ‘Height’.

My expectation would be with 50% and ‘Volume’, that a pallet filled by all items going to all customers within a shopping mall and having a volume utilization of for example 55%, a PU would be created. So let’s check and trigger the function ‘Create PUs Based on PB’ for all FUs selected:

You notice that all FUs are now planned and Execution Documents (PUs) created.

Let’s take a closer look:

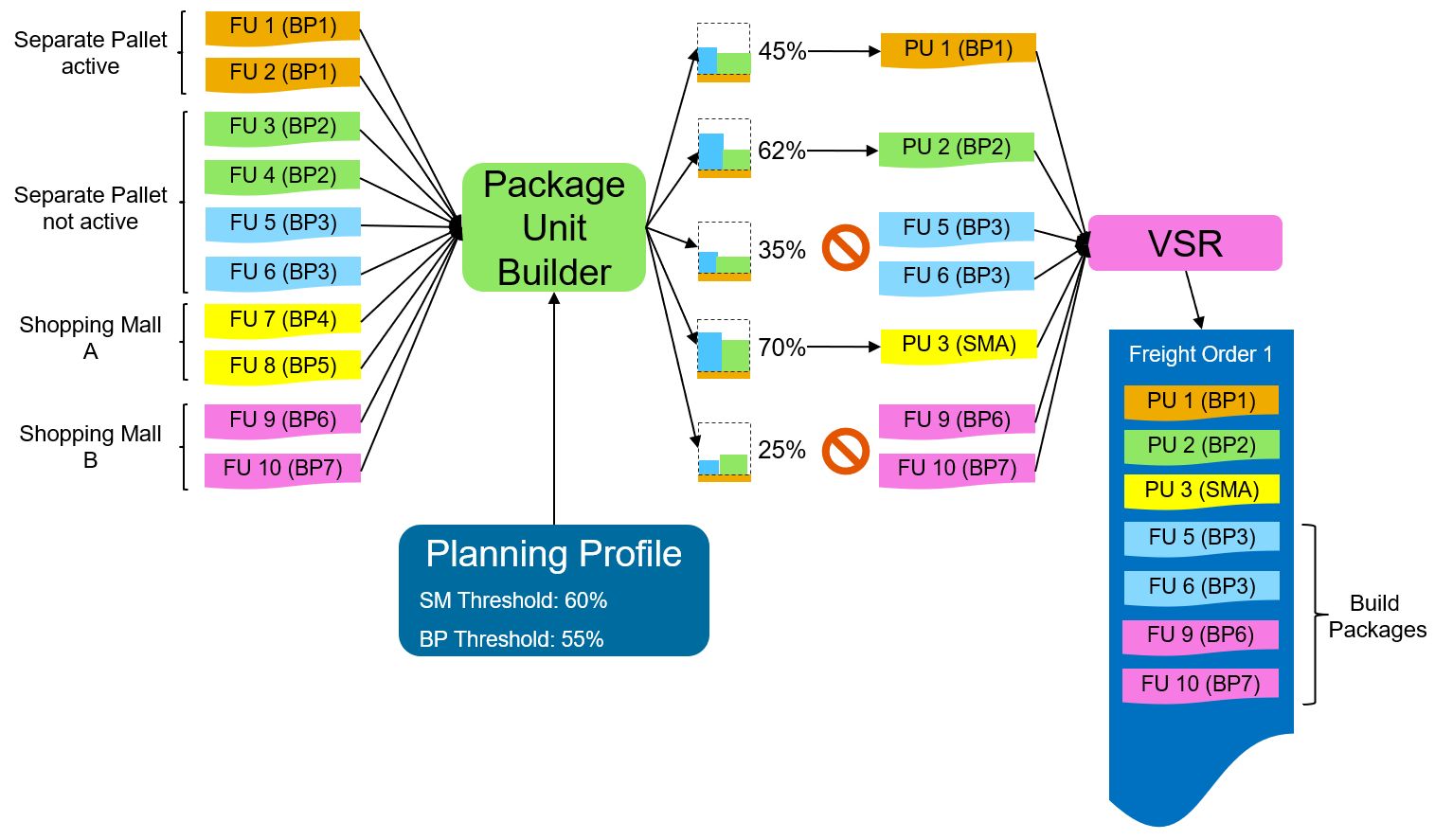

Here is the explanation for what has happened.

The example does not leave a FU unplanned. If I would raise the thresholds, some of them would not be created.

Note that the location soft grouping is preferred over the single customer. So even if a customer within a shopping mall would order sufficient quantity for a well utilized pallet, it would be combined with other items for customers within the same shopping mall.

You also notice an additional thing: As soon as a single pallet fulfills the threshold, all pallets are transferred into the PU (you can still select a PU type that reflects a 1:1 what would lead to multiple PUs, but I guess in this scenario it would be better to use a type allowing multiple top level packages within a PU). It would make little sense to improve the searching for these items by keeping most of them on a separate pallet and force the delivery person to search for the rest on product grouped pallets. The result can be uneven distributions (like in PU $2), but for this ideas like spreading / balancing could be applied (move items from the full pallet to the low pallet).

The Package Units created represent reality as you would want them to go together from a routing perspective and also be packaged together. Huge improvement for the VSR as it does not have to work on package estimates for those FUs.

Here a model showing an example including unplanned FUs:

Package Units could so far only be create early during Freight Unit Building, manually, or automatically using the feature ‘Create PU based on PB’ (Create Package Units based on Package Building). For the later, only the ‘Exclusive Package for Customer’ (MKS93) was considered. When the feature detected one or multiple Freight Units for the same customer having the indicator set, it created Package Units and assigned the Freight Units to it. The FUs going to other customers not having the indicator stayed untouched. All further planning happens based on the created PUs and the still unplanned FUs.

The automatic PU creation is also possible automatically using a background report (/SCMTMS/PLN_PB_FU_BGD). In addition, the PU creation can be added as a pre-processing step to automatic planning strategies (method VSR_CEPU).

It became clear quickly that the PUs are a powerful tool to improve and streamline the planning. Luckily, the feature to create them automatically was designed from the vey beginning having in mind that additional Freight Unit attributes could be a trigger to do so.

So let’s check how this evolved. I have a scenario with a location soft group represented by a location hierarchy. It contains two shopping malls each having 2 customer locations (shops, restaurants,…). A location soft group means for my scenario that I prefer all to be delivered items going to customers within a unique group on one or multiple separated pallets if the utilization is good enough (see MKS106) during consolidation package building. If the defined threshold is not fulfilled, I prefer the items to be packaged following a product grouping to enable easy search for the delivery person.

Nice feature to consider this during consolidation package building, but it would be even better to transfer those top level package fulfilling a utilization threshold into Package Units before calling the VSR optimizer.

Location Soft Group

I set the location hierarchy in the Package Building Profile.

In my planning session in the Transportation Cockpit I have multiple Freight Units going to customers within the shopping malls, but also FUs for customers outside.

And now I activate the new enhanced creation of PUs in the Planning Profile:

Here you now have the option to define a ‘Location Group Utilization Threshold’, a ‘BP Utilization Threshold’, and select a ‘Dimension for Utilization Threshold’. The first 2 are percentages and for the dimension you can select ‘Volume’, ‘Weight’, or ‘Height’.

My expectation would be with 50% and ‘Volume’, that a pallet filled by all items going to all customers within a shopping mall and having a volume utilization of for example 55%, a PU would be created. So let’s check and trigger the function ‘Create PUs Based on PB’ for all FUs selected:

You notice that all FUs are now planned and Execution Documents (PUs) created.

Let’s take a closer look:

Here is the explanation for what has happened.

- PU ($4) created for the FU having the ‘Separate Package for Customer’ indicator.

- PUs ($5,$6) created per shopping mall as the location utilization threshold was fulfilled

- PUs ($2,$3) created per customer

The example does not leave a FU unplanned. If I would raise the thresholds, some of them would not be created.

Note that the location soft grouping is preferred over the single customer. So even if a customer within a shopping mall would order sufficient quantity for a well utilized pallet, it would be combined with other items for customers within the same shopping mall.

You also notice an additional thing: As soon as a single pallet fulfills the threshold, all pallets are transferred into the PU (you can still select a PU type that reflects a 1:1 what would lead to multiple PUs, but I guess in this scenario it would be better to use a type allowing multiple top level packages within a PU). It would make little sense to improve the searching for these items by keeping most of them on a separate pallet and force the delivery person to search for the rest on product grouped pallets. The result can be uneven distributions (like in PU $2), but for this ideas like spreading / balancing could be applied (move items from the full pallet to the low pallet).

The Package Units created represent reality as you would want them to go together from a routing perspective and also be packaged together. Huge improvement for the VSR as it does not have to work on package estimates for those FUs.

Here a model showing an example including unplanned FUs:

- SAP Managed Tags:

- SAP Transportation Management

Labels:

3 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- Transforming Cell Gene Therapy Operations: The Power of Integrated Scheduling and Resource Planning Systems in Supply Chain Management Blogs by SAP

- Transforming Digital Supply Chains with AI in Supply Chain Management Blogs by SAP

- Advanced Scheduling Board - F5460 in Supply Chain Management Blogs by SAP

- SAP IBP: Cost-optimized supply plan considering capacities and material constraints and explore co-production using 3rd party in Supply Chain Management Blogs by Members

- Warehouse Management System Boosts Productivity- Here’s How in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 8 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |