- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Monday Knowledge Snippet (MKS) – 107 S/4HANA 2020 ...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member18

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-20-2020

9:51 AM

One of the limitations of the Supply Chain Execution Package Builder was the strict assignment of intermediate packaging to a single next level or top level package material. In scenarios, where for example products are first cartonized and then packaged onto pallets, everything packaged into the same carton material ends up on the same pallet material. For customers using standardized carton materials (so for example only a single carton material at all), this do not allow to differentiate the next level packaging.

To give an example: A company packages tea and coffee products. Everything goes into a single carton material. By default, everything goes onto euro pallets. Here is the product hierarchy:

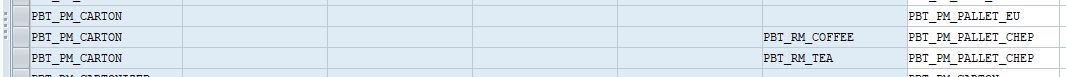

In the package type assignment, the following definitions have been made:

Running the package building in test report /SCMB/TEST_PB with 2 products, we can see full cartons created only containing a single product and a mixed carton:

Now imagine that the business requires that all tea products shall be separated and go onto chep pallets. This was not possible so far without using the package builder enhancement spot, but now there is a new option in the package type assignment available called 'Contained Material'. So we add another entry to the scenario indicating that cartons that contain tea products (we can use either a product number or a reference material number here) go to the chep pallet:

Running the scenario with the same product quantities leads no to this:

We can see that the carton with tea only is really separated and packaged onto the chep pallet, while the full coffee carton remains together with the mixed carton.

As an alternative, we could imagine that the customer wants to separate the mixed cartons from the full product cartons. To do so, we adjust the assignments in the following manner:

As a result, we get:

This also works in combination with products going directly to the pallets.

Another step forward.

To give an example: A company packages tea and coffee products. Everything goes into a single carton material. By default, everything goes onto euro pallets. Here is the product hierarchy:

In the package type assignment, the following definitions have been made:

Running the package building in test report /SCMB/TEST_PB with 2 products, we can see full cartons created only containing a single product and a mixed carton:

Now imagine that the business requires that all tea products shall be separated and go onto chep pallets. This was not possible so far without using the package builder enhancement spot, but now there is a new option in the package type assignment available called 'Contained Material'. So we add another entry to the scenario indicating that cartons that contain tea products (we can use either a product number or a reference material number here) go to the chep pallet:

Running the scenario with the same product quantities leads no to this:

We can see that the carton with tea only is really separated and packaged onto the chep pallet, while the full coffee carton remains together with the mixed carton.

As an alternative, we could imagine that the customer wants to separate the mixed cartons from the full product cartons. To do so, we adjust the assignments in the following manner:

As a result, we get:

This also works in combination with products going directly to the pallets.

Another step forward.

- SAP Managed Tags:

- SAP Transportation Management

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

3 -

Expert Insights

12 -

Expert Insights

36 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

60 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

15

Related Content

- SAP Materials Management Introduction in Supply Chain Management Blogs by Members

- Enriched version of Transportation Management Incident Creation with Support Assistant in Supply Chain Management Blogs by SAP

- From Concept to Creation: UX, PM, and Dev's Role in User-Friendly UIs in Supply Chain Management Blogs by SAP

- From Chaos to Clarity: Master Data Management (MDM) role in Digital Transformation success in Supply Chain Management Blogs by Members

- Data Science with SAP HANA Predictive Analytics Library (PAL), AMDP (ABAP Managed Database Procedure) and Core Data Services (CDS) Table Functions in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 7 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |