- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Monday Knowledge Snippet (MKS) – 105 S/4HANA 2020 ...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member18

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-20-2020

6:08 AM

With the Release to Customer for S/4HANA 2020 (see great blog about the Transportation Management features here), I can announce the availability of the Unified Package Builder. Sometimes the road is not too long from vision (MKS100) to reality as we understand the sense of urgency for improved integration across the application portfolio. As the vision blog already explains the motivation, I will jump right into the solution.

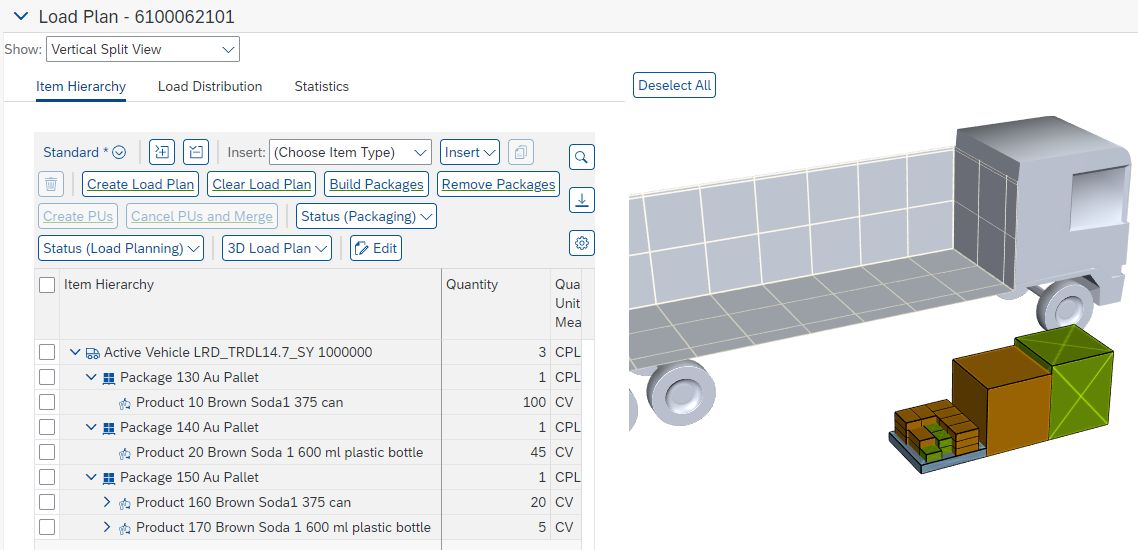

In my scenario, I have a freight order for which I want to apply package building. If I do so (in this case in the Transportation Cockpit because this gives me the best overview about my transportation plan, but also possible in the document itself), I get the item hierarchy created and a nice visualization in the load plan area:

There are 2 full quantity pallets based on the definitions in the material master, each containing a single product. You notice the exact item positions in the visualization of the mixed pallet, so we know that the detailed mixed package building using the package builder optimizer must have been applied. This was configured in the Package Builder Profile defined in the Planning Profile used for the Transportation Cockpit session.

We can also run this scenario independently of the Transportation Management in the Package Builder test report /SCMB/TEST_PB:

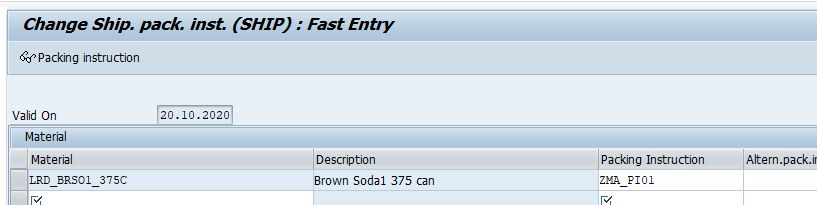

So far, so good. But in your scenario you can not use the Supply Chain Execution Package Builder! You have to use existing Packing Instructions to fulfill customer requirements. You have thousands of them and you do not want to transfer them in whatever way into the master data or SCE PB using enhancement spots!

Okay, so let's take a look into the Package Building Profile. Here quite a lot of things changed in S/4HANA 2020, but I focus on the UPB settings. There is a new area available called 'Package Building Engine', where you can select the PI (the Package Builder is the default selection). This enables you to make entries on the Packing Instruction tab. Here the link to the PI relevant settings in made by defining the Packing Transaction Profile (you can find this in the customizing under Logistics - General -> Handling Unit Management -> Automatic Packing) and the HU Object.

The Packing Transaction Profile should look familiar to you when the PI is already used in other applications.

This links to the determination procedures for the packing instructions. Here are the required definitions in POP1 and POF1.

You notice compared to the full quantity definitions in this PI the product splits at 95 CV instead of 100 CV.

You notice compared to the full quantity definitions in this PI the product splits at 40 CV instead of 45 CV.

If you run this now in the Package Builder test report with the very same product quantities, the result is this:

PI successfully applied! No mixed pallet created. The attributes of the result pallets should match what is defined in the PIs.

Technically this was achieved using the new API /SCMB/IF_PB_UNIFIED, where you can find further information about the structure of the items to be packaged, the result items, package details and item positions.

Mission accomplished? For sure not, as all of this only makes sense when the business processes are using the UPB. In S/4HANA Transportation Management, all processes requiring package building (during Freight Unit Building, Consolidation Package Building, Package Unit Creation) are already switched to the new API. This enables our customers to use exactly what they require as package building can be configured per freight unit building rule, document type, or planning session.

To prove the application integration, we can adjust our planning profile and switch to our new Package Building Profile having the PI activated:

We run package building again for the very same Freight Order

The result reflects the PI definitions. We see no exact item positions as the PI can not return this.

Even if I have demonstrated this with the PI, you might have noticed the other option Packaging Specification. This works in a similar manner and is also ready to go.

Here is where we are at: PI and PS are integrated as encapsulated components without any change. So they run (including whatever enhancements you have made) like in any other context. The API for the items to be packaged is pretty lean as we stick to the fields the TM can supply. I am aware that the PI determination can be based on many other fields using conditions, so this will be depending on the customer requirements an area of further enhancements. Together with the first customers to use the API we will manage to get this done.

Use cases combining for example PI and SCE PB (build cartons using PI and create pallets using PB, create full pallets using PI and mixed pallets using PB) are not supported yet.

Even though it is said that I miss the big picture of logistics processes, I hope the UPB can help S/4HANA customers to tackle their scenarios better. As with any new component, we are eager to hear your feedback and ideas.

More info: TM Podcast Black Belt Edition - Package Builder

In my scenario, I have a freight order for which I want to apply package building. If I do so (in this case in the Transportation Cockpit because this gives me the best overview about my transportation plan, but also possible in the document itself), I get the item hierarchy created and a nice visualization in the load plan area:

There are 2 full quantity pallets based on the definitions in the material master, each containing a single product. You notice the exact item positions in the visualization of the mixed pallet, so we know that the detailed mixed package building using the package builder optimizer must have been applied. This was configured in the Package Builder Profile defined in the Planning Profile used for the Transportation Cockpit session.

We can also run this scenario independently of the Transportation Management in the Package Builder test report /SCMB/TEST_PB:

So far, so good. But in your scenario you can not use the Supply Chain Execution Package Builder! You have to use existing Packing Instructions to fulfill customer requirements. You have thousands of them and you do not want to transfer them in whatever way into the master data or SCE PB using enhancement spots!

Okay, so let's take a look into the Package Building Profile. Here quite a lot of things changed in S/4HANA 2020, but I focus on the UPB settings. There is a new area available called 'Package Building Engine', where you can select the PI (the Package Builder is the default selection). This enables you to make entries on the Packing Instruction tab. Here the link to the PI relevant settings in made by defining the Packing Transaction Profile (you can find this in the customizing under Logistics - General -> Handling Unit Management -> Automatic Packing) and the HU Object.

The Packing Transaction Profile should look familiar to you when the PI is already used in other applications.

This links to the determination procedures for the packing instructions. Here are the required definitions in POP1 and POF1.

You notice compared to the full quantity definitions in this PI the product splits at 95 CV instead of 100 CV.

You notice compared to the full quantity definitions in this PI the product splits at 40 CV instead of 45 CV.

If you run this now in the Package Builder test report with the very same product quantities, the result is this:

PI successfully applied! No mixed pallet created. The attributes of the result pallets should match what is defined in the PIs.

Technically this was achieved using the new API /SCMB/IF_PB_UNIFIED, where you can find further information about the structure of the items to be packaged, the result items, package details and item positions.

Mission accomplished? For sure not, as all of this only makes sense when the business processes are using the UPB. In S/4HANA Transportation Management, all processes requiring package building (during Freight Unit Building, Consolidation Package Building, Package Unit Creation) are already switched to the new API. This enables our customers to use exactly what they require as package building can be configured per freight unit building rule, document type, or planning session.

To prove the application integration, we can adjust our planning profile and switch to our new Package Building Profile having the PI activated:

We run package building again for the very same Freight Order

and get this result:

The result reflects the PI definitions. We see no exact item positions as the PI can not return this.

Even if I have demonstrated this with the PI, you might have noticed the other option Packaging Specification. This works in a similar manner and is also ready to go.

Here is where we are at: PI and PS are integrated as encapsulated components without any change. So they run (including whatever enhancements you have made) like in any other context. The API for the items to be packaged is pretty lean as we stick to the fields the TM can supply. I am aware that the PI determination can be based on many other fields using conditions, so this will be depending on the customer requirements an area of further enhancements. Together with the first customers to use the API we will manage to get this done.

Use cases combining for example PI and SCE PB (build cartons using PI and create pallets using PB, create full pallets using PI and mixed pallets using PB) are not supported yet.

Even though it is said that I miss the big picture of logistics processes, I hope the UPB can help S/4HANA customers to tackle their scenarios better. As with any new component, we are eager to hear your feedback and ideas.

More info: TM Podcast Black Belt Edition - Package Builder

- SAP Managed Tags:

- SAP Transportation Management

Labels:

7 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

46 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

67 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

18

Related Content

- VSR Optimizer considering net weight for maximum utilization instead of gross weight in Supply Chain Management Q&A

- RISE with SAP advanced PLM package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

- Automatic packing for outbound delivery using Unified Package Builder- Customer Connect - 281072 in Supply Chain Management Blogs by SAP

- Automatic packing of EWM Outbound delivery based on Packing Instructions (UPB) in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 5 | |

| 5 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |